Increased Efficiency and Productivity with Vacuum Glass Lifters

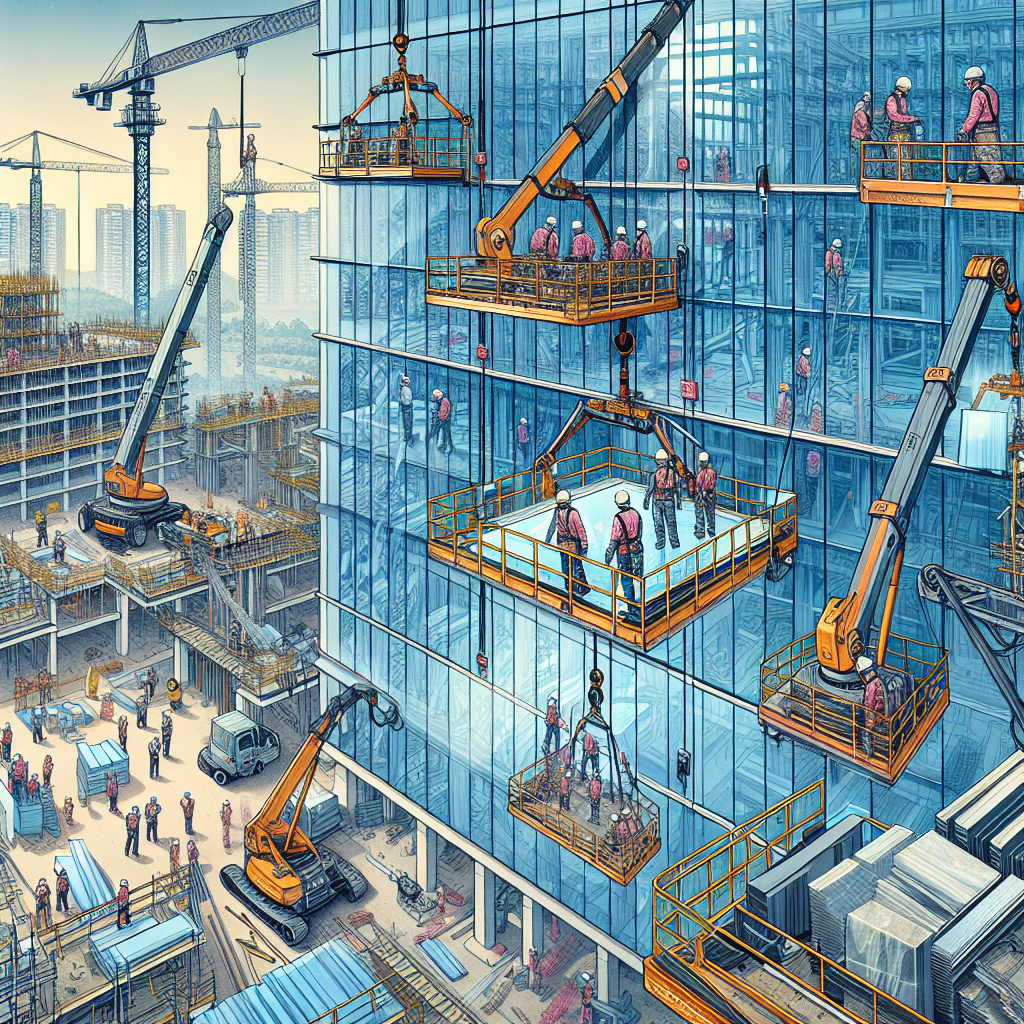

Vacuum glass lifters have become an essential tool for large projects due to their ability to increase efficiency and productivity. These innovative devices have revolutionized the way glass panels are handled and installed, making them a must-have for any construction or renovation project.

One of the main advantages of vacuum glass lifters is their ability to lift and transport heavy glass panels with ease. Traditional methods of handling glass panels often require multiple workers and specialized equipment, which can be time-consuming and labor-intensive. With vacuum glass lifters, a single operator can easily maneuver and position glass panels, saving both time and manpower.

The efficiency of vacuum glass lifters is further enhanced by their quick and easy setup. These devices are designed to be user-friendly, with intuitive controls and adjustable settings that allow operators to customize the lifting process to suit their specific needs. This means that even workers with minimal training can quickly learn how to operate a vacuum glass lifter, reducing the learning curve and increasing overall productivity.

Another key advantage of vacuum glass lifters is their ability to handle glass panels of various sizes and shapes. Whether it’s a small window pane or a large glass curtain wall, these versatile devices can securely grip and lift glass panels of different dimensions. This eliminates the need for multiple lifting tools or the risk of damaging the glass during the handling process.

Furthermore, vacuum glass lifters are designed with safety in mind. These devices are equipped with advanced safety features such as audible alarms, visual indicators, and emergency stop buttons to ensure the well-being of both the operator and the glass panels. The vacuum suction cups used in these lifters are specifically designed to provide a secure grip on the glass, minimizing the risk of accidents or damage.

In addition to their efficiency and safety benefits, vacuum glass lifters also offer cost savings for large projects. By reducing the need for additional manpower and specialized equipment, these devices can significantly lower labor costs. Moreover, the speed and ease of glass panel installation with vacuum glass lifters can help shorten project timelines, resulting in overall cost savings.

The increased efficiency and productivity offered by vacuum glass lifters have made them a game-changer in the construction industry. These devices have not only simplified the handling and installation of glass panels but have also improved the overall quality of work. With their ability to lift heavy loads, handle various glass panel sizes, and ensure safety, vacuum glass lifters have become an indispensable tool for large projects.

In conclusion, vacuum glass lifters have become a must-have for large projects due to their ability to increase efficiency and productivity. These devices offer numerous advantages, including easy handling of heavy glass panels, quick setup, versatility in handling different glass sizes, enhanced safety features, and cost savings. With their ability to streamline the glass installation process, vacuum glass lifters have become an essential tool for any construction or renovation project.

Enhanced Safety Measures Provided by Vacuum Glass Lifters

Enhanced Safety Measures Provided by Vacuum Glass Lifters

When it comes to large construction projects, safety should always be a top priority. The use of vacuum glass lifters has become increasingly popular in recent years due to their ability to enhance safety measures on these types of projects. These innovative devices provide a secure and efficient way to handle and transport large glass panels, reducing the risk of accidents and injuries.

One of the key safety features of vacuum glass lifters is their ability to securely grip and hold glass panels in place. Traditional methods of lifting and moving glass panels often involve the use of clamps or suction cups, which can be prone to slipping or failing under the weight of the glass. Vacuum glass lifters, on the other hand, use a powerful vacuum suction system to create a strong and reliable grip on the glass. This ensures that the glass panels remain securely in place throughout the lifting and transportation process, minimizing the risk of accidents caused by glass panels falling or shifting.

In addition to their secure grip, vacuum glass lifters also offer enhanced stability during the lifting and transportation of glass panels. These devices are typically equipped with multiple suction cups or pads that distribute the weight of the glass evenly, reducing the risk of the glass becoming unbalanced or tipping over. This stability is particularly important when working with large and heavy glass panels, as any instability could lead to accidents and injuries.

Furthermore, vacuum glass lifters are designed with safety features that prevent the glass from being released accidentally. These devices often have a manual release valve that allows the operator to control the release of the vacuum suction, ensuring that the glass is only released when intended. This feature provides an added layer of safety, as it prevents the glass from being dropped or released prematurely, which could cause damage to the glass or pose a risk to nearby workers.

Another safety benefit of vacuum glass lifters is their ability to reduce the physical strain on workers. Lifting and moving large glass panels manually can be a physically demanding task, putting strain on the back, shoulders, and arms of workers. Vacuum glass lifters eliminate the need for manual lifting, as they are designed to do the heavy lifting for the workers. This not only reduces the risk of musculoskeletal injuries but also increases productivity by allowing workers to focus on other tasks instead of spending time and energy on lifting and moving heavy glass panels.

In conclusion, vacuum glass lifters are a must-have for large construction projects due to the enhanced safety measures they provide. These devices offer a secure grip and enhanced stability, reducing the risk of accidents caused by glass panels falling or shifting. They also have safety features that prevent accidental release of the glass and reduce the physical strain on workers. By investing in vacuum glass lifters, construction companies can ensure the safety of their workers and improve the efficiency of their projects.

Cost-Effective Solutions for Large Projects with Vacuum Glass Lifters

Why Vacuum Glass Lifters Are a Must-Have for Large Projects

When it comes to large projects that involve handling heavy glass panels, having the right equipment is crucial. One such equipment that has proven to be a game-changer in the industry is the vacuum glass lifter. These innovative devices have revolutionized the way glass panels are handled, making them a must-have for any large project.

One of the main reasons why vacuum glass lifters are so popular is their cost-effectiveness. Traditional methods of lifting and moving glass panels often require a large workforce and specialized equipment, which can be expensive. In contrast, vacuum glass lifters are designed to be efficient and require minimal manpower. With just one operator, these lifters can easily lift and transport heavy glass panels, saving both time and money.

Another advantage of vacuum glass lifters is their versatility. These devices are designed to handle a wide range of glass panel sizes and shapes, making them suitable for various projects. Whether you are working on a high-rise building with large floor-to-ceiling windows or a small storefront with delicate glass displays, vacuum glass lifters can handle it all. This versatility eliminates the need for multiple lifting devices, further reducing costs and increasing efficiency.

In addition to their cost-effectiveness and versatility, vacuum glass lifters also offer enhanced safety features. Traditional methods of lifting glass panels often involve the risk of accidents and injuries. With vacuum glass lifters, the risk of accidents is significantly reduced. These lifters use suction cups to securely grip the glass panels, ensuring a stable and safe lifting process. Furthermore, many vacuum glass lifters are equipped with additional safety features such as alarms and sensors that alert the operator of any potential issues, further enhancing the safety of the operation.

Furthermore, vacuum glass lifters are designed to be user-friendly. They are equipped with intuitive controls that are easy to operate, even for those with limited experience. This means that you don’t need to invest in extensive training for your workforce to use these lifters effectively. The simplicity of operation also reduces the risk of human error, further enhancing the safety and efficiency of the lifting process.

Lastly, vacuum glass lifters are designed to be durable and long-lasting. They are built with high-quality materials that can withstand the rigors of heavy-duty use. This means that once you invest in a vacuum glass lifter, you can expect it to serve you for many years to come, providing a reliable and cost-effective solution for your large projects.

In conclusion, vacuum glass lifters are a must-have for any large project that involves handling heavy glass panels. Their cost-effectiveness, versatility, enhanced safety features, user-friendliness, and durability make them an invaluable tool in the industry. By investing in a vacuum glass lifter, you can significantly reduce costs, increase efficiency, and ensure the safety of your workforce. So, if you are planning a large project that involves glass panels, make sure to consider the benefits of vacuum glass lifters.