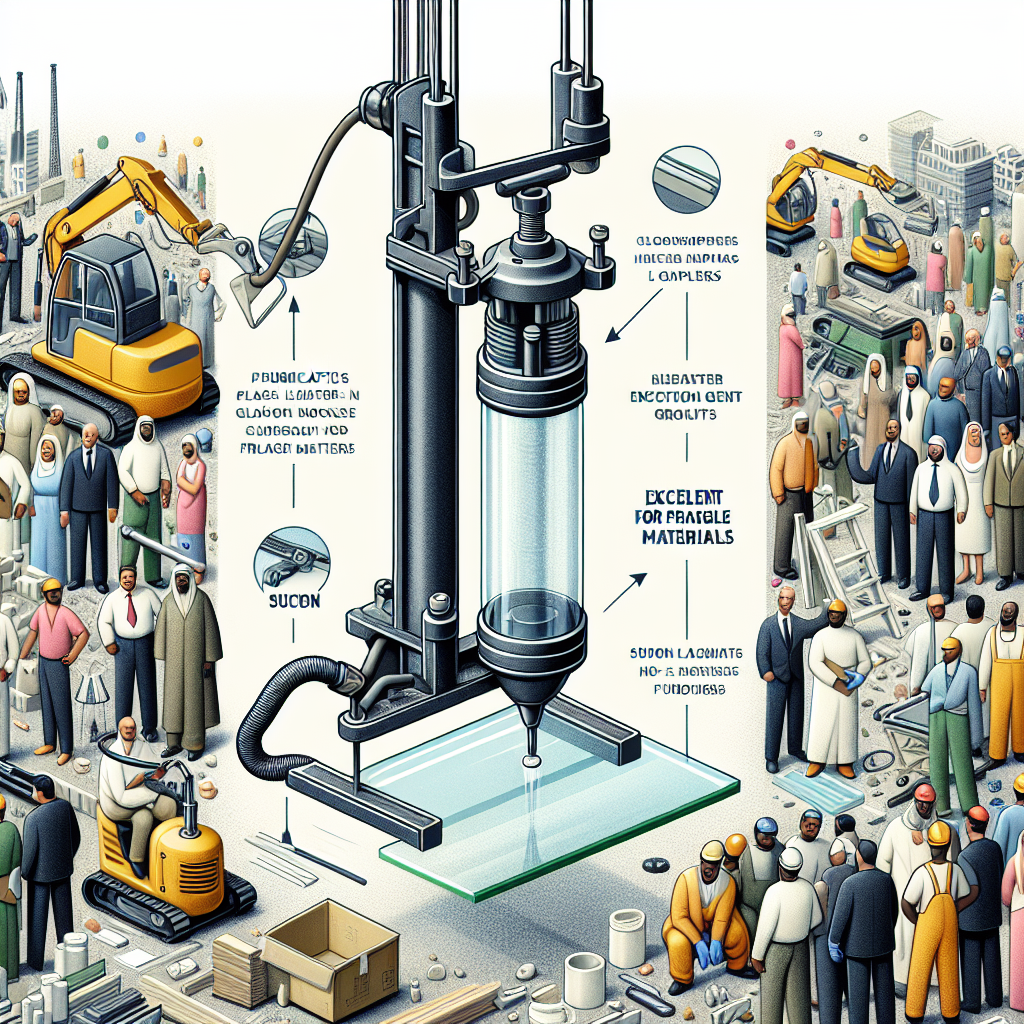

Benefits of Using Pneumatic Glass Lifters for Fragile Glass Panels

Glass panels are delicate and require careful handling to prevent damage. When it comes to lifting and moving these fragile panels, pneumatic glass lifters are the perfect solution. These specialized lifting devices offer numerous benefits that make them ideal for working with fragile glass.

One of the main advantages of using pneumatic glass lifters is their ability to provide a secure grip on the glass panels. These lifters use suction cups that create a vacuum seal, ensuring a strong hold on the glass. This eliminates the risk of the panels slipping or falling during the lifting process, minimizing the chances of breakage.

Furthermore, pneumatic glass lifters are designed to distribute the weight of the glass evenly. This prevents any undue stress or pressure on specific areas of the panel, reducing the risk of cracks or fractures. The even weight distribution also makes it easier to maneuver the glass panels, allowing for precise placement without compromising their structural integrity.

Another benefit of pneumatic glass lifters is their versatility. These lifters can be used with various types of glass panels, including those with different shapes, sizes, and thicknesses. Whether you are working with large, heavy panels or smaller, more delicate ones, pneumatic glass lifters can accommodate your needs. This versatility makes them a valuable tool for a wide range of glass-related projects.

In addition to their versatility, pneumatic glass lifters are also highly adjustable. They can be easily adapted to different angles and positions, allowing for greater flexibility in handling glass panels. This adjustability is particularly useful when working with curved or irregularly shaped glass, as it ensures a secure grip and precise control during lifting and placement.

Furthermore, pneumatic glass lifters are designed with safety in mind. These devices are equipped with features such as audible alarms and visual indicators that alert operators to any potential issues or malfunctions. This ensures that any problems can be addressed promptly, minimizing the risk of accidents or damage to the glass panels.

Moreover, pneumatic glass lifters are ergonomically designed to reduce strain and fatigue on the operator. These lifters are equipped with handles and controls that are easy to reach and operate, allowing for comfortable and efficient use. This not only improves productivity but also reduces the risk of injuries caused by repetitive or strenuous movements.

Lastly, pneumatic glass lifters are cost-effective. Investing in these lifters can save both time and money in the long run. The secure grip and precise control provided by pneumatic glass lifters minimize the risk of breakage, reducing the need for costly repairs or replacements. Additionally, the efficiency and versatility of these lifters allow for faster and more efficient glass installation, saving valuable time and resources.

In conclusion, pneumatic glass lifters offer numerous benefits that make them perfect for handling fragile glass panels. Their secure grip, even weight distribution, versatility, adjustability, safety features, ergonomic design, and cost-effectiveness make them an invaluable tool for any glass-related project. By investing in pneumatic glass lifters, you can ensure the safe and efficient handling of fragile glass panels, minimizing the risk of damage and maximizing productivity.

How Pneumatic Glass Lifters Ensure Safe Handling of Fragile Glass Panels

Glass panels are delicate and require careful handling to prevent damage. When it comes to lifting and moving these fragile objects, pneumatic glass lifters are the perfect solution. These specialized lifting devices use air pressure to create a vacuum seal, allowing for safe and secure transportation of glass panels.

One of the main advantages of pneumatic glass lifters is their ability to distribute the weight of the glass evenly. This is crucial when dealing with large and heavy glass panels, as uneven weight distribution can lead to cracks or breakage. The vacuum seal created by the pneumatic lifter ensures that the glass is held securely in place, preventing any shifting or movement during transportation.

In addition to providing even weight distribution, pneumatic glass lifters also offer a high level of control and precision. The operator can easily adjust the lifting force to accommodate different sizes and weights of glass panels. This allows for a more customized and tailored approach to lifting, ensuring that the glass is handled with the utmost care.

Furthermore, pneumatic glass lifters are designed with safety in mind. These devices are equipped with multiple safety features to prevent accidents and injuries. For example, many pneumatic lifters have an automatic release valve that allows for quick and controlled release of the glass panel. This eliminates the risk of sudden drops or jerky movements that could cause the glass to shatter.

Another safety feature of pneumatic glass lifters is their ability to maintain a secure grip even in the event of a power failure. The vacuum seal created by the lifter is not dependent on electricity, meaning that the glass panel will remain securely held in place even if the power goes out. This provides peace of mind to both the operator and the client, knowing that their fragile glass panels are protected at all times.

Pneumatic glass lifters are also highly versatile and can be used in a variety of settings. Whether it’s in a construction site, a manufacturing facility, or a glass installation project, these lifters can handle the job. They can be easily attached to cranes, forklifts, or other lifting equipment, making them a convenient and efficient choice for any glass handling task.

In conclusion, pneumatic glass lifters are the perfect solution for safely handling fragile glass panels. Their ability to distribute weight evenly, provide precise control, and offer multiple safety features make them an ideal choice for any glass lifting operation. Whether it’s for a small residential project or a large-scale commercial installation, pneumatic glass lifters ensure that the glass is transported and installed without any damage or breakage. So, if you’re in the business of working with glass panels, investing in a pneumatic glass lifter is a wise decision that will save you time, money, and headaches in the long run.

Key Features and Specifications of Pneumatic Glass Lifters for Fragile Glass Panels

Pneumatic glass lifters have become increasingly popular in the construction and manufacturing industries due to their ability to safely handle fragile glass panels. These lifters are specifically designed to provide a secure and efficient way to transport and install glass panels without causing any damage. In this article, we will explore the key features and specifications of pneumatic glass lifters that make them perfect for fragile glass panels.

One of the most important features of pneumatic glass lifters is their suction cup system. These lifters are equipped with multiple suction cups that create a strong vacuum seal on the glass panel. This vacuum seal ensures that the glass panel remains securely attached to the lifter throughout the lifting and transportation process. The suction cups are made from high-quality materials that are gentle on the glass surface, preventing any scratches or marks.

Another key feature of pneumatic glass lifters is their adjustable lifting capacity. These lifters come in various models with different lifting capacities, allowing them to handle glass panels of different sizes and weights. The lifting capacity can be easily adjusted to accommodate the specific requirements of each glass panel, ensuring a safe and secure lift. This versatility makes pneumatic glass lifters suitable for a wide range of glass panel installations, from small windows to large glass facades.

In addition to their adjustable lifting capacity, pneumatic glass lifters also offer a range of lifting options. These lifters can be operated manually or with the help of a remote control. The manual operation allows for precise control over the lifting process, while the remote control option provides convenience and ease of use. This flexibility in lifting options ensures that the glass panels can be lifted and positioned with utmost accuracy and precision.

Furthermore, pneumatic glass lifters are designed with safety in mind. These lifters are equipped with safety features such as audible alarms and visual indicators that alert the operator in case of any issues or malfunctions. The lifters also have a built-in safety valve that prevents the glass panel from falling in the event of a sudden loss of pressure. These safety features provide peace of mind to the operators and minimize the risk of accidents or damage to the glass panels.

Another important specification of pneumatic glass lifters is their portability. These lifters are compact and lightweight, making them easy to transport and maneuver on construction sites or manufacturing facilities. They can be easily moved from one location to another, allowing for efficient and quick glass panel installations. The portability of pneumatic glass lifters also makes them suitable for projects that require multiple lifts in different areas.

In conclusion, pneumatic glass lifters are the perfect solution for handling fragile glass panels. Their key features and specifications, such as the suction cup system, adjustable lifting capacity, various lifting options, safety features, and portability, make them an ideal choice for construction and manufacturing industries. These lifters provide a secure and efficient way to transport and install glass panels without causing any damage. With pneumatic glass lifters, fragile glass panels can be handled with utmost care and precision, ensuring a successful and safe installation process.