Increased Efficiency and Productivity with Pneumatic Glass Lifters

Why Glass Installers Choose Pneumatic Glass Lifters

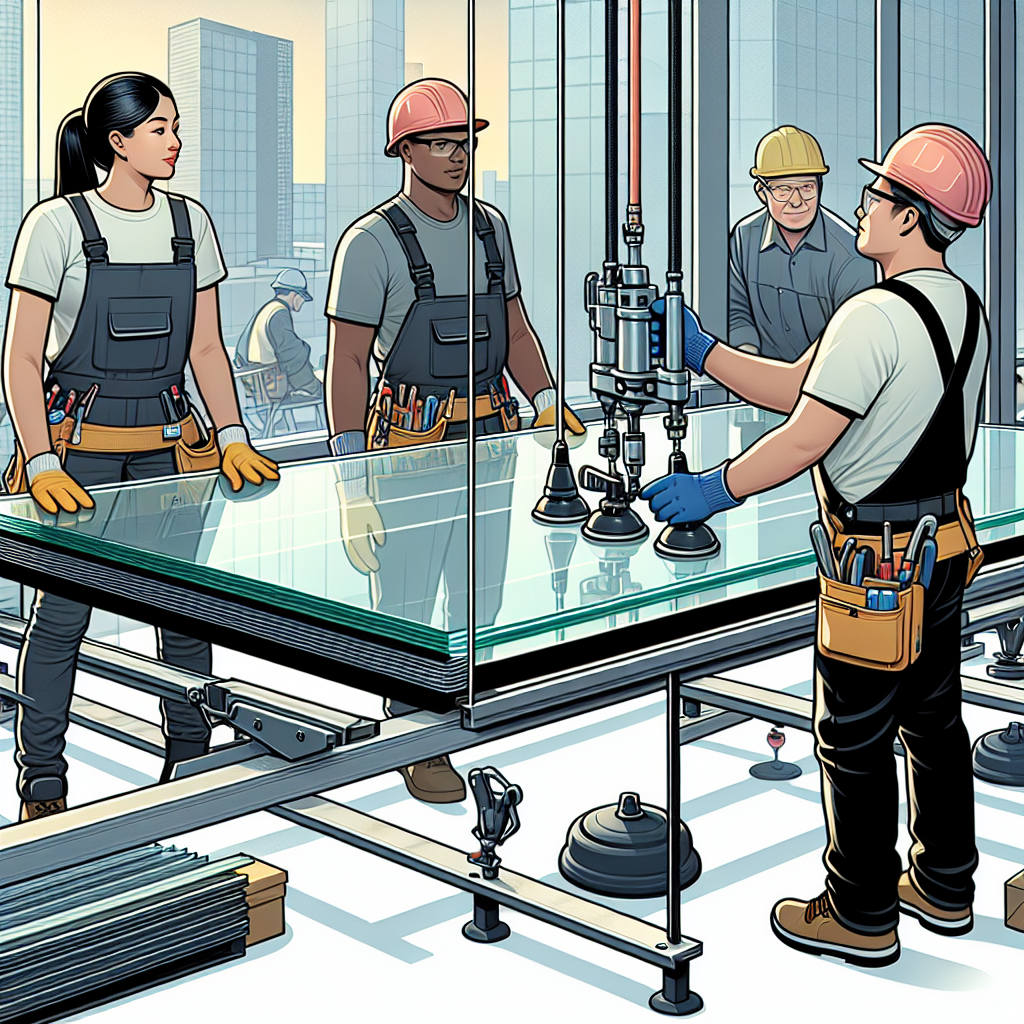

Glass installation is a delicate and precise process that requires the use of specialized equipment to ensure the safety of both the installers and the glass itself. One such piece of equipment that has become increasingly popular among glass installers is the pneumatic glass lifter. These powerful machines offer a range of benefits that contribute to increased efficiency and productivity on the job.

One of the main reasons why glass installers choose pneumatic glass lifters is their ability to handle heavy loads with ease. These lifters are designed to lift and transport large sheets of glass, which can weigh hundreds of pounds. By utilizing the power of compressed air, pneumatic glass lifters can effortlessly lift and maneuver these heavy loads, reducing the strain on the installers and minimizing the risk of accidents or injuries.

In addition to their strength, pneumatic glass lifters also offer a high level of precision. The lifting mechanism of these machines allows for precise control over the movement of the glass, ensuring that it is positioned accurately and securely in place. This level of precision is crucial in glass installation, as even the slightest misalignment can compromise the integrity of the installation. With pneumatic glass lifters, installers can have confidence in the accuracy of their work, resulting in a higher quality finished product.

Another advantage of pneumatic glass lifters is their versatility. These machines are designed to be adaptable to various types of glass installations, including vertical, horizontal, and overhead applications. This versatility allows glass installers to tackle a wide range of projects with a single piece of equipment, eliminating the need for multiple tools and reducing setup time. By streamlining the installation process, pneumatic glass lifters contribute to increased efficiency and productivity on the job site.

Furthermore, pneumatic glass lifters are designed with the safety of the installers in mind. These machines are equipped with safety features such as non-slip pads and vacuum sensors that ensure a secure grip on the glass at all times. This reduces the risk of accidents and damage to the glass, providing peace of mind to both the installers and their clients. Additionally, the use of pneumatic glass lifters eliminates the need for manual lifting and carrying of heavy glass sheets, further reducing the risk of strain or injury to the installers.

In conclusion, pneumatic glass lifters have become the preferred choice of glass installers due to their ability to increase efficiency and productivity on the job. These machines offer the strength and precision necessary for handling heavy loads of glass, while also providing versatility and safety features that contribute to a higher quality finished product. By investing in pneumatic glass lifters, glass installers can streamline their operations, reduce the risk of accidents or injuries, and ultimately deliver exceptional results to their clients.

Enhanced Safety Measures Provided by Pneumatic Glass Lifters

Glass installation can be a challenging and potentially dangerous task. The weight and fragility of glass make it susceptible to accidents and injuries. That’s why glass installers rely on pneumatic glass lifters to enhance safety measures during the installation process.

One of the key advantages of using pneumatic glass lifters is their ability to handle heavy loads with ease. These lifters are equipped with powerful suction cups that create a vacuum seal on the glass surface, allowing it to be lifted and moved effortlessly. This eliminates the need for manual lifting, reducing the risk of strain or back injuries for the installers.

Furthermore, pneumatic glass lifters are designed to provide a secure grip on the glass, ensuring that it remains stable during transportation and installation. The vacuum seal created by the suction cups creates a strong bond between the lifter and the glass, preventing any slippage or accidental drops. This feature is particularly crucial when working with large or oversized glass panels, which can be extremely heavy and difficult to handle manually.

In addition to their lifting capabilities, pneumatic glass lifters also offer enhanced control and precision during the installation process. These lifters are equipped with adjustable arms and suction cups, allowing installers to position the glass accurately and align it with the desired location. This level of control ensures that the glass is installed correctly, reducing the risk of accidents or damage caused by misalignment.

Another safety feature provided by pneumatic glass lifters is their ability to absorb shocks and vibrations. Glass panels are susceptible to cracking or shattering when subjected to sudden impacts or vibrations. Pneumatic lifters are designed to minimize these risks by providing a cushioning effect during transportation and installation. The suction cups absorb shocks and vibrations, reducing the likelihood of glass breakage and ensuring a safer working environment for the installers.

Moreover, pneumatic glass lifters are equipped with safety mechanisms that prevent accidental releases. These mechanisms include pressure sensors and alarms that alert the operator if the vacuum seal is compromised. This ensures that the glass remains securely attached to the lifter at all times, minimizing the risk of accidents or injuries caused by unexpected drops.

Furthermore, pneumatic glass lifters are designed to be versatile and adaptable to different installation scenarios. They can be used on various types of glass, including tempered, laminated, and insulated glass. This versatility allows glass installers to use the same lifter for different projects, reducing the need for multiple specialized tools and equipment.

In conclusion, pneumatic glass lifters offer enhanced safety measures for glass installers. Their ability to handle heavy loads, provide a secure grip, offer control and precision, absorb shocks and vibrations, and prevent accidental releases make them an indispensable tool in the glass installation industry. By choosing pneumatic glass lifters, installers can ensure a safer working environment and minimize the risk of accidents or injuries during the installation process.

Cost-effectiveness and Time-saving Benefits of Pneumatic Glass Lifters

Glass installation can be a challenging and time-consuming task, requiring careful handling and precision. To simplify this process, many glass installers are turning to pneumatic glass lifters. These innovative tools offer a range of cost-effectiveness and time-saving benefits that make them a popular choice in the industry.

One of the primary reasons why glass installers choose pneumatic glass lifters is their cost-effectiveness. Traditional methods of glass installation often involve the use of manual labor or heavy machinery, both of which can be expensive. Pneumatic glass lifters, on the other hand, offer a more affordable alternative. These lifters are typically lightweight and portable, reducing the need for additional equipment or manpower. This not only saves money but also allows for greater flexibility in terms of project logistics.

In addition to being cost-effective, pneumatic glass lifters also save time. Time is of the essence in any construction project, and glass installation is no exception. Pneumatic glass lifters are designed to streamline the installation process, allowing for quicker and more efficient work. These lifters are equipped with powerful suction cups that securely hold the glass in place, eliminating the need for manual lifting and positioning. This not only reduces the risk of accidents and injuries but also speeds up the overall installation time.

Furthermore, pneumatic glass lifters offer a level of precision that is difficult to achieve with traditional methods. The suction cups on these lifters can be adjusted to accommodate different glass sizes and shapes, ensuring a perfect fit every time. This eliminates the need for time-consuming adjustments or modifications, allowing installers to complete their work with greater accuracy and efficiency.

Another advantage of pneumatic glass lifters is their versatility. These lifters can be used for a wide range of glass installation projects, from windows and doors to skylights and glass partitions. This versatility makes them a valuable investment for glass installers, as they can be used on multiple projects without the need for additional equipment. This not only saves money but also reduces the need for storage space, making pneumatic glass lifters a practical choice for both large and small-scale operations.

In conclusion, pneumatic glass lifters offer a range of cost-effectiveness and time-saving benefits that make them a preferred choice for glass installers. Their lightweight and portable design, combined with powerful suction cups, streamline the installation process and reduce the need for additional equipment or manpower. The precision and versatility of these lifters further enhance their value, allowing for quick and efficient work on a variety of glass installation projects. With all these advantages, it’s no wonder why glass installers are increasingly turning to pneumatic glass lifters as their tool of choice.