Benefits of Using a Vacuum Glass Lifter Sucker for Glass Handling

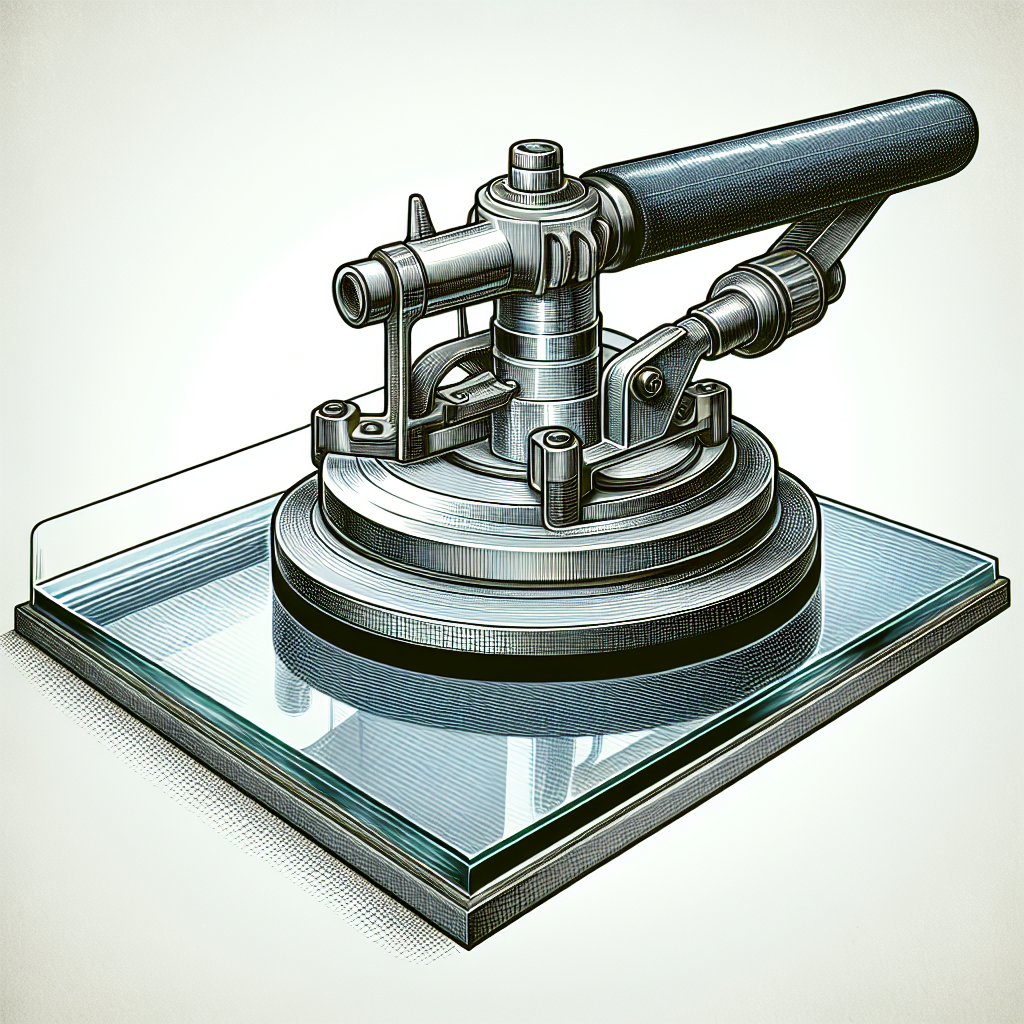

Glass handling can be a challenging task, especially when dealing with large and heavy pieces. The risk of accidents and injuries is high, and the potential for damage to the glass is always present. However, with the advent of vacuum glass lifter suckers, glass handling has become much easier and safer. These innovative devices have revolutionized the industry, providing numerous benefits to those involved in glass handling.

One of the key benefits of using a vacuum glass lifter sucker is the increased safety it offers. Traditional methods of glass handling often involve manual lifting, which can put a strain on the body and increase the risk of accidents. With a vacuum glass lifter sucker, the glass is securely held in place by suction, eliminating the need for manual lifting. This significantly reduces the risk of injuries and accidents, making glass handling a much safer process.

In addition to improved safety, vacuum glass lifter suckers also offer increased efficiency. These devices are designed to handle glass with ease, allowing for quick and effortless lifting and moving. This means that glass can be transported and positioned much faster, saving valuable time and increasing productivity. Whether it’s in a construction site or a glass manufacturing facility, the use of a vacuum glass lifter sucker can greatly improve efficiency and streamline operations.

Another advantage of using a vacuum glass lifter sucker is the ability to handle a wide range of glass sizes and shapes. These devices are adjustable and can be customized to accommodate different glass dimensions. Whether it’s a small window pane or a large glass panel, a vacuum glass lifter sucker can securely hold and transport it. This versatility makes these devices suitable for various applications, from residential glass installation to commercial glass fabrication.

Furthermore, vacuum glass lifter suckers are designed to minimize the risk of damage to the glass. The suction cups are made from materials that are gentle on the glass surface, preventing scratches and other forms of damage. Additionally, the suction force can be adjusted to ensure a secure grip without exerting excessive pressure on the glass. This careful handling reduces the likelihood of costly mistakes and ensures that the glass remains in pristine condition throughout the handling process.

Lastly, vacuum glass lifter suckers are user-friendly and easy to operate. They are equipped with intuitive controls that allow for precise positioning and movement of the glass. The devices are also lightweight and portable, making them convenient to use in different locations. With minimal training, anyone can learn to operate a vacuum glass lifter sucker effectively, further enhancing its usability and practicality.

In conclusion, the benefits of using a vacuum glass lifter sucker for glass handling are undeniable. These devices offer increased safety, improved efficiency, versatility in handling different glass sizes and shapes, and minimize the risk of damage to the glass. With their user-friendly design and ease of operation, vacuum glass lifter suckers have become an essential tool for anyone involved in glass handling. Whether it’s for residential or commercial applications, these devices provide a hassle-free solution for the transportation and positioning of glass, making the entire process much smoother and more efficient.

How Vacuum Glass Lifter Suckers Improve Efficiency in Glass Installation

Glass installation can be a challenging and time-consuming task. The fragility of glass makes it prone to breakage, and its weight can make it difficult to handle. However, with the advent of vacuum glass lifter suckers, the process of glass installation has become much more efficient and hassle-free.

One of the key benefits of using vacuum glass lifter suckers is the improved efficiency they bring to the glass installation process. These devices are designed to securely grip glass panels, allowing them to be lifted and moved with ease. This eliminates the need for manual lifting, which can be physically demanding and time-consuming. With a vacuum glass lifter sucker, glass panels can be effortlessly lifted and positioned, saving both time and energy.

In addition to improving efficiency, vacuum glass lifter suckers also enhance safety during glass installation. The suction cups on these devices create a strong and reliable grip on the glass, reducing the risk of accidents and breakage. This is particularly important when working with large and heavy glass panels, as any mishandling can result in serious injuries or damage. By using a vacuum glass lifter sucker, installers can have peace of mind knowing that the glass is securely held in place.

Furthermore, vacuum glass lifter suckers offer versatility in glass handling. These devices are designed to accommodate different sizes and shapes of glass panels, making them suitable for a wide range of installation projects. Whether it’s a small window or a large glass facade, a vacuum glass lifter sucker can provide the necessary support and stability. This versatility allows installers to tackle various glass installation tasks without the need for multiple tools or equipment.

Another advantage of using vacuum glass lifter suckers is their ease of use. These devices are typically lightweight and portable, making them easy to maneuver and transport. They are also equipped with user-friendly controls, allowing installers to adjust the suction power and release the glass panels with precision. This simplicity of operation ensures that even inexperienced users can handle glass installation tasks efficiently and safely.

Moreover, vacuum glass lifter suckers contribute to a cleaner and more professional installation. The suction cups on these devices leave no marks or residue on the glass, ensuring a pristine finish. This is particularly important in architectural projects where aesthetics play a crucial role. By using a vacuum glass lifter sucker, installers can ensure that the glass panels are handled with care and precision, resulting in a high-quality installation.

In conclusion, vacuum glass lifter suckers have revolutionized the glass installation industry by improving efficiency, enhancing safety, offering versatility, and providing ease of use. These devices have become an indispensable tool for installers, allowing them to handle glass panels with ease and precision. Whether it’s a small residential window or a large commercial facade, a vacuum glass lifter sucker is the key to hassle-free glass handling. With their numerous benefits, it’s no wonder that these devices have become a staple in the glass installation industry.

Safety Measures and Best Practices for Operating Vacuum Glass Lifter Suckers

Safety Measures and Best Practices for Operating Vacuum Glass Lifter Suckers

When it comes to handling glass, safety should always be the top priority. Glass is a fragile material that can easily break, causing serious injuries. That’s why it’s crucial to follow safety measures and best practices when operating a vacuum glass lifter sucker. In this article, we will discuss some important guidelines to ensure hassle-free glass handling.

First and foremost, before using a vacuum glass lifter sucker, it’s essential to inspect the equipment thoroughly. Check for any signs of damage or wear and tear. Make sure all the components are in good working condition, including the vacuum pump, suction cups, and control panel. If you notice any issues, it’s crucial to address them immediately and not use the equipment until it’s repaired or replaced.

Once you have confirmed that the vacuum glass lifter sucker is in proper working order, it’s time to prepare the glass for lifting. Before attempting to lift the glass, ensure that it is clean and free from any debris or contaminants. Even the smallest particles can affect the suction and compromise the lifting process. Additionally, make sure the glass is dry to prevent any slipping or sliding during the lifting operation.

When positioning the vacuum glass lifter sucker on the glass, it’s important to place it in the center of the pane. This ensures an even distribution of weight and minimizes the risk of the glass cracking or breaking. Avoid placing the suction cups too close to the edges, as this can create stress points and increase the chances of damage.

Before activating the vacuum pump, double-check that the suction cups are securely attached to the glass. Ensure that they are aligned properly and have a tight seal. This step is crucial to prevent any air leakage and maintain a strong grip on the glass. Once you are confident that everything is in place, you can activate the vacuum pump.

During the lifting operation, it’s important to maintain a steady and controlled movement. Avoid sudden jerks or movements that can put unnecessary stress on the glass. It’s also crucial to keep a firm grip on the control panel and be aware of your surroundings. Make sure there is enough clearance for the glass to be lifted without hitting any obstacles or causing damage to nearby objects.

When lowering the glass, it’s important to do so slowly and carefully. Gradually release the suction by activating the release valve on the vacuum glass lifter sucker. This allows the glass to be safely and smoothly placed in its desired location. Avoid dropping or releasing the glass abruptly, as this can lead to accidents and damage.

After completing the glass handling operation, it’s important to clean and maintain the vacuum glass lifter sucker. Remove any debris or dirt from the suction cups and ensure that all components are properly cleaned and lubricated. Regular maintenance will prolong the lifespan of the equipment and ensure its optimal performance.

In conclusion, operating a vacuum glass lifter sucker requires adherence to safety measures and best practices. By following these guidelines, you can ensure hassle-free glass handling and minimize the risk of accidents or damage. Remember to inspect the equipment, prepare the glass properly, position the suction cups correctly, maintain a steady movement, and clean and maintain the equipment regularly. With these precautions in place, you can handle glass with confidence and efficiency.