Benefits of Using a Vacuum Glass Lifter Sucker for Handling Large Glass Panels

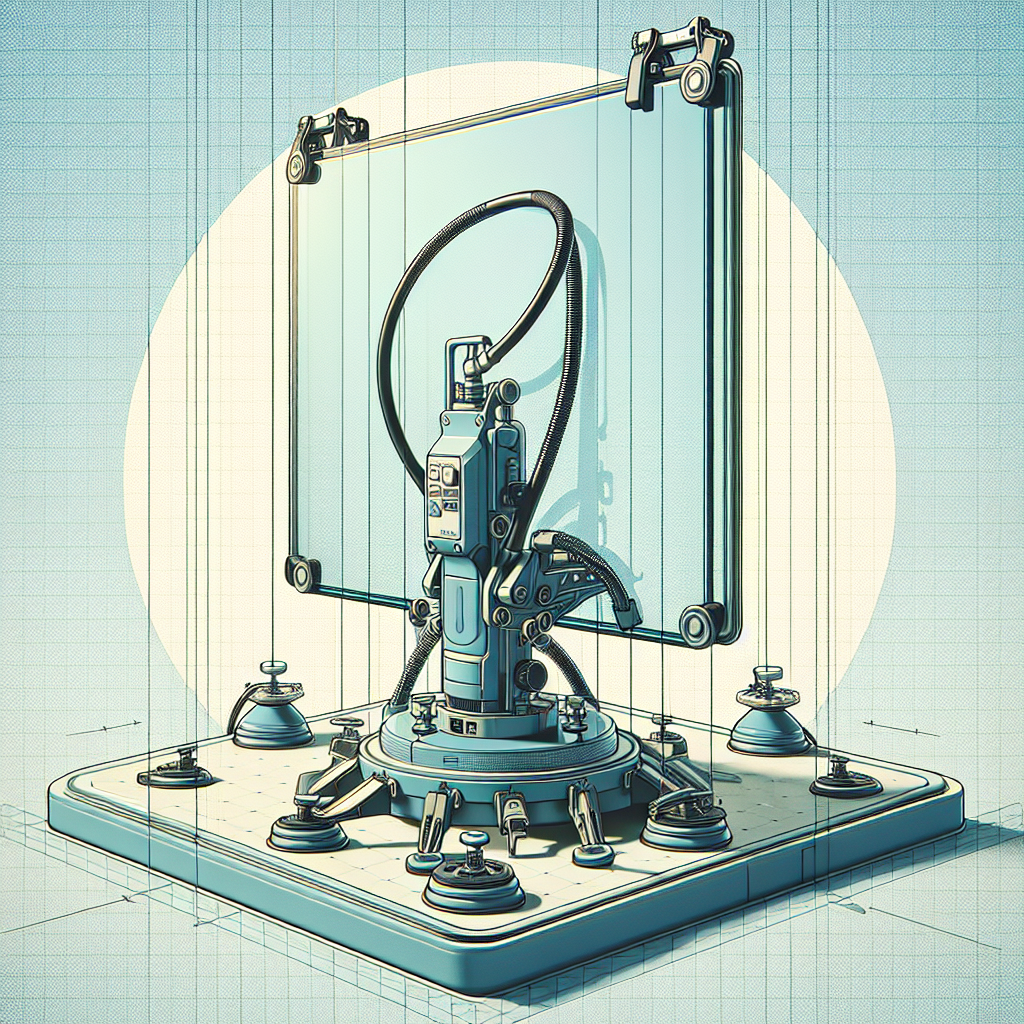

Vacuum Glass Lifter Sucker: The Ideal Tool for Handling Large Glass Panels

When it comes to handling large glass panels, it can be a daunting task. The sheer size and weight of these panels make them difficult to maneuver and transport safely. However, with the advent of vacuum glass lifter suckers, this task has become much easier and more efficient. In this article, we will explore the benefits of using a vacuum glass lifter sucker for handling large glass panels.

One of the primary advantages of using a vacuum glass lifter sucker is its ability to securely grip and lift large glass panels. The suction cups on the lifter create a strong vacuum seal, ensuring that the glass panel remains firmly in place during transport. This eliminates the risk of the panel slipping or falling, which could result in damage or injury. The lifter’s ability to securely grip the glass panel provides peace of mind to the operator, knowing that the panel is held securely and will not be compromised during handling.

Another benefit of using a vacuum glass lifter sucker is its ease of use. The lifter is designed to be user-friendly, with simple controls and intuitive operation. This means that even operators with minimal experience can quickly learn how to use the lifter effectively. The lifter’s ergonomic design also reduces the strain on the operator, making it easier and more comfortable to handle large glass panels. This not only improves efficiency but also reduces the risk of operator fatigue or injury.

Furthermore, using a vacuum glass lifter sucker significantly speeds up the handling process. Traditional methods of handling large glass panels often require multiple operators and specialized equipment. This can be time-consuming and costly. However, with a vacuum glass lifter sucker, a single operator can easily handle large glass panels, reducing the need for additional manpower. The lifter’s efficiency allows for quicker turnaround times, increasing productivity and reducing overall project timelines.

In addition to its efficiency, a vacuum glass lifter sucker also offers versatility in handling different types of glass panels. Whether it’s a large window, a glass door, or a decorative glass panel, the lifter can adapt to various shapes and sizes. This versatility makes it an ideal tool for a wide range of applications, from construction sites to manufacturing facilities. The lifter’s ability to handle different types of glass panels eliminates the need for multiple tools, simplifying the handling process and reducing costs.

Lastly, using a vacuum glass lifter sucker promotes safety in the workplace. The lifter’s secure grip and stability minimize the risk of accidents or injuries during the handling process. Additionally, the lifter’s design includes safety features such as audible alarms and visual indicators, alerting the operator to any potential issues or malfunctions. This ensures that the operator can take immediate action to prevent accidents or damage.

In conclusion, a vacuum glass lifter sucker is the ideal tool for handling large glass panels. Its ability to securely grip and lift glass panels, ease of use, efficiency, versatility, and safety features make it a valuable asset in any industry that deals with large glass panels. By investing in a vacuum glass lifter sucker, businesses can improve productivity, reduce costs, and ensure the safety of their workers.

How to Choose the Right Vacuum Glass Lifter Sucker for Your Glass Handling Needs

Vacuum Glass Lifter Sucker: The Ideal Tool for Handling Large Glass Panels

When it comes to handling large glass panels, having the right tool is essential. One such tool that has gained popularity in recent years is the vacuum glass lifter sucker. This innovative device is designed to make the process of lifting and moving heavy glass panels much easier and safer. However, with so many options available on the market, it can be overwhelming to choose the right vacuum glass lifter sucker for your specific needs. In this article, we will discuss some important factors to consider when selecting the perfect tool for your glass handling requirements.

First and foremost, it is crucial to consider the weight capacity of the vacuum glass lifter sucker. Different models come with varying weight limits, so it is essential to choose one that can handle the weight of the glass panels you will be working with. It is always better to opt for a vacuum lifter with a higher weight capacity to ensure that it can handle any future projects as well.

Another important factor to consider is the size and shape of the glass panels you will be handling. Some vacuum glass lifters are designed specifically for flat glass panels, while others can handle curved or irregularly shaped ones as well. It is important to choose a lifter that is compatible with the type of glass panels you will be working with to ensure a secure grip and prevent any accidents or damage.

Additionally, it is crucial to consider the type of surface the glass panels will be placed on. Some vacuum glass lifters are designed for smooth surfaces, while others can handle rough or textured surfaces as well. If you will be working on surfaces that are not perfectly smooth, it is important to choose a lifter that has suction cups or pads specifically designed for such surfaces to ensure a strong and secure grip.

Furthermore, it is important to consider the power source of the vacuum glass lifter sucker. Some models are powered by electricity, while others are battery-operated. Electric-powered lifters are generally more powerful and can handle heavier loads, but they require a power source nearby. On the other hand, battery-operated lifters offer more flexibility and can be used in areas where electricity is not readily available. It is important to choose a power source that suits your specific needs and working environment.

Lastly, it is crucial to consider the safety features of the vacuum glass lifter sucker. Look for features such as audible alarms or warning lights that indicate when the suction is weakening or when the battery is running low. These safety features can help prevent accidents and ensure that the glass panels are handled with utmost care.

In conclusion, choosing the right vacuum glass lifter sucker for your glass handling needs is essential to ensure efficiency, safety, and ease of use. Consider factors such as weight capacity, compatibility with different glass panel shapes, suitability for different surface types, power source, and safety features. By carefully evaluating these factors, you can select the perfect tool that will make your glass handling tasks a breeze.

Safety Tips for Using a Vacuum Glass Lifter Sucker to Handle Large Glass Panels

Safety Tips for Using a Vacuum Glass Lifter Sucker to Handle Large Glass Panels

When it comes to handling large glass panels, using a vacuum glass lifter sucker can be a game-changer. This tool is specifically designed to make the process of lifting and moving heavy glass panels much easier and safer. However, it is important to keep in mind that using a vacuum glass lifter sucker requires proper knowledge and caution to ensure the safety of both the operator and the glass panels.

First and foremost, before using a vacuum glass lifter sucker, it is crucial to inspect the equipment thoroughly. Check for any signs of damage or wear and tear. Make sure that all the components, such as the vacuum pads and the suction cups, are in good condition and securely attached. Any damaged or faulty parts should be replaced immediately to avoid any accidents or mishaps during the lifting process.

Another important safety tip is to ensure that the glass panel is clean and free from any debris or contaminants. Even the smallest particles can affect the suction power of the vacuum glass lifter sucker, compromising its ability to securely hold the glass panel. Therefore, it is essential to clean the glass surface thoroughly before attempting to lift it. This will not only ensure a stronger grip but also prevent any scratches or damages to the glass.

Furthermore, it is crucial to assess the weight and dimensions of the glass panel before using the vacuum glass lifter sucker. Each lifter has its own weight capacity, and exceeding this limit can lead to accidents and injuries. Always refer to the manufacturer’s guidelines and specifications to determine the maximum weight that the lifter can handle. Additionally, consider the size and shape of the glass panel to ensure that it can be safely lifted and maneuvered without any issues.

In addition to inspecting the equipment and assessing the glass panel, it is important to pay attention to the environment in which the lifting operation will take place. Ensure that the surface where the glass panel will be placed is clean, level, and free from any obstructions. This will provide a stable and secure base for the glass panel, reducing the risk of it slipping or falling during the lifting process. Moreover, be aware of any potential hazards in the surrounding area, such as overhead obstacles or uneven terrain, and take appropriate measures to mitigate these risks.

Lastly, always follow proper lifting techniques when using a vacuum glass lifter sucker. Maintain a stable and balanced posture, keeping your back straight and using your legs to lift the glass panel. Avoid twisting or jerking movements that can strain your muscles or cause the glass panel to shift unexpectedly. Additionally, communicate with your team members if you are working in a group, ensuring that everyone is coordinated and aware of their roles and responsibilities.

In conclusion, using a vacuum glass lifter sucker can greatly simplify the process of handling large glass panels. However, it is essential to prioritize safety and follow these tips to prevent accidents and injuries. Thoroughly inspect the equipment, clean the glass panel, assess the weight and dimensions, consider the environment, and use proper lifting techniques. By doing so, you can ensure a smooth and secure lifting operation, protecting both yourself and the valuable glass panels.