Benefits of Using Vacuum Glass Lifter Suckers in Glazing Projects

Vacuum Glass Lifter Sucker: A Key Component in Modern Glazing

Benefits of Using Vacuum Glass Lifter Suckers in Glazing Projects

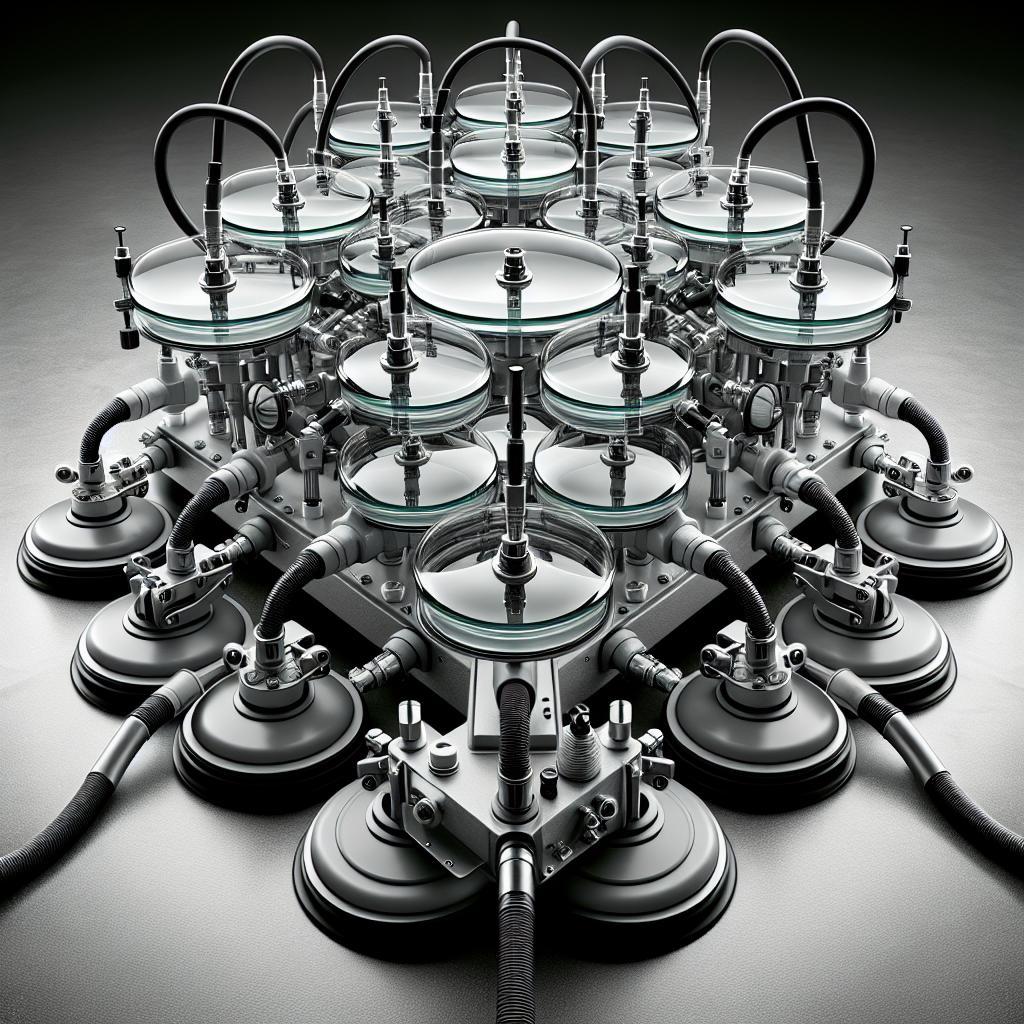

In the world of modern glazing, the use of vacuum glass lifter suckers has become an essential component. These innovative devices have revolutionized the way glass is handled and installed, offering numerous benefits that make them indispensable in any glazing project.

One of the primary advantages of using vacuum glass lifter suckers is their ability to provide a secure and reliable grip on glass panels. Traditional methods of lifting and moving glass often involved the use of clamps or suction cups, which could be prone to slippage or damage to the glass surface. Vacuum glass lifter suckers, on the other hand, utilize a powerful vacuum seal to create a strong bond between the lifter and the glass, ensuring a firm and stable grip.

This secure grip not only enhances safety during the lifting and installation process but also allows for greater precision and control. With a vacuum glass lifter sucker, glaziers can confidently maneuver glass panels into position without the fear of accidental drops or shifts. This level of control is particularly crucial when working with large or heavy glass panels, where even the slightest movement can have disastrous consequences.

Another significant benefit of using vacuum glass lifter suckers is their versatility. These devices are designed to accommodate a wide range of glass sizes and shapes, making them suitable for various glazing projects. Whether it’s a small window pane or a large curtain wall, vacuum glass lifter suckers can be easily adjusted to fit the specific dimensions of the glass panel, ensuring a secure grip regardless of its size or shape.

Furthermore, vacuum glass lifter suckers are not limited to vertical installations. They can also be used for horizontal or angled glazing projects, providing flexibility and convenience for glaziers. This versatility eliminates the need for multiple lifting devices, streamlining the glazing process and saving both time and effort.

In addition to their practical advantages, vacuum glass lifter suckers also offer economic benefits. By reducing the risk of glass breakage or damage during installation, these devices help minimize costly mistakes and rework. The secure grip provided by vacuum glass lifter suckers also allows for faster installation times, increasing overall productivity and efficiency on the job site.

Moreover, the use of vacuum glass lifter suckers can significantly reduce the physical strain on glaziers. Lifting and maneuvering heavy glass panels manually can be physically demanding and potentially lead to injuries. Vacuum glass lifter suckers alleviate this burden by taking on the majority of the lifting work, allowing glaziers to focus on the precise positioning and installation of the glass.

In conclusion, vacuum glass lifter suckers have become an indispensable tool in modern glazing projects. Their ability to provide a secure grip, enhance control and precision, accommodate various glass sizes and shapes, and offer economic and ergonomic benefits make them a key component in the glazing industry. By incorporating vacuum glass lifter suckers into their workflow, glaziers can ensure safer, more efficient, and cost-effective installations, ultimately delivering superior results to their clients.

How Vacuum Glass Lifter Suckers Improve Efficiency and Safety in Glazing

Vacuum glass lifter suckers have become a key component in modern glazing, revolutionizing the way glass is handled and installed. These innovative devices have greatly improved efficiency and safety in the glazing industry, making the process of installing glass panels faster, easier, and more secure.

One of the main advantages of using vacuum glass lifter suckers is the significant increase in efficiency they provide. In the past, glaziers had to rely on manual labor and physical strength to lift and maneuver heavy glass panels. This not only required a great deal of effort but also took a considerable amount of time. With the introduction of vacuum glass lifter suckers, however, the process has been streamlined and accelerated.

These devices are equipped with powerful suction cups that create a vacuum seal between the lifter and the glass panel. This allows glaziers to effortlessly lift and transport glass panels of various sizes and weights. The suction cups are designed to securely grip the glass, eliminating the risk of slippage or accidents during transportation. This not only saves time but also reduces the need for additional manpower, resulting in significant cost savings for glazing companies.

In addition to improving efficiency, vacuum glass lifter suckers also play a crucial role in enhancing safety during the glazing process. The suction cups are made from high-quality materials that are specifically designed to withstand the weight and pressure of glass panels. This ensures that the lifter remains securely attached to the glass, even when it is being lifted or moved.

Furthermore, these devices are equipped with safety features such as audible alarms and visual indicators that alert the operator if the vacuum seal is compromised. This provides an added layer of protection, as it allows glaziers to quickly identify and rectify any issues before accidents occur. The use of vacuum glass lifter suckers significantly reduces the risk of glass panels falling or shattering, protecting both the workers and the expensive glass materials.

Moreover, vacuum glass lifter suckers are versatile tools that can be used in a wide range of glazing applications. They can be used to install glass panels in various settings, including commercial buildings, residential properties, and even high-rise structures. The suction cups can be easily adjusted to accommodate different glass sizes and shapes, making them suitable for a variety of projects.

In conclusion, vacuum glass lifter suckers have revolutionized the glazing industry by improving efficiency and safety. These devices have made the process of handling and installing glass panels faster, easier, and more secure. With their powerful suction cups and advanced safety features, vacuum glass lifter suckers have become an indispensable tool for glaziers. They not only save time and money but also protect workers and expensive glass materials. Whether it is a small residential project or a large-scale commercial development, vacuum glass lifter suckers are a key component in modern glazing.

Choosing the Right Vacuum Glass Lifter Sucker for Your Glazing Needs

Vacuum glass lifter suckers have become a key component in modern glazing, revolutionizing the way glass is handled and installed. These innovative devices use suction to securely grip and lift glass panels, making the glazing process safer and more efficient. However, with a wide range of vacuum glass lifter suckers available on the market, it is important to choose the right one for your specific glazing needs.

When selecting a vacuum glass lifter sucker, there are several factors to consider. First and foremost, you need to determine the weight capacity required for your project. Different suckers have varying weight limits, so it is crucial to choose one that can handle the weight of the glass panels you will be working with. It is always better to choose a sucker with a higher weight capacity than you think you will need, to ensure safety and avoid any accidents.

Another important consideration is the size and shape of the glass panels you will be lifting. Some vacuum glass lifter suckers are designed specifically for flat glass, while others are suitable for curved or irregularly shaped panels. It is essential to choose a sucker that is compatible with the type of glass you will be working with to ensure a secure grip and prevent any damage to the panels.

Additionally, you should take into account the surface condition of the glass. If the glass has a rough or textured surface, you will need a vacuum glass lifter sucker with a stronger suction power to ensure a reliable grip. On the other hand, if the glass has a smooth surface, a sucker with a lower suction power may be sufficient. It is important to carefully assess the surface condition of the glass and choose a sucker that can provide the necessary suction strength.

Furthermore, consider the environment in which the glazing work will be carried out. If you will be working outdoors or in a dusty environment, it is advisable to choose a vacuum glass lifter sucker with a built-in filter to prevent dust and debris from clogging the suction cups. This will help maintain optimal suction power and ensure a secure grip on the glass panels.

In addition to these technical considerations, it is also important to choose a vacuum glass lifter sucker from a reputable manufacturer. Look for a company with a proven track record in producing high-quality and reliable lifting equipment. Reading customer reviews and testimonials can also provide valuable insights into the performance and durability of different suckers.

Lastly, consider the additional features and accessories that may be available with the vacuum glass lifter sucker. Some models come with adjustable suction cups or extension arms, allowing for greater flexibility and ease of use. Others may have battery-powered or electric options, providing convenience and versatility in different working environments.

In conclusion, choosing the right vacuum glass lifter sucker is crucial for ensuring the success and safety of your glazing projects. Consider factors such as weight capacity, glass panel size and shape, surface condition, working environment, and additional features when making your selection. By carefully assessing your specific glazing needs and choosing a sucker from a reputable manufacturer, you can enhance the efficiency and effectiveness of your glazing operations.