Cleaning and Maintenance Techniques for Vacuum Glass Lifter Suckers

Top Tips for Maintaining Your Vacuum Glass Lifter Sucker

Vacuum glass lifter suckers are essential tools for lifting and moving heavy glass panels. They provide a secure grip and make the task of handling glass much easier. However, like any tool, vacuum glass lifter suckers require regular maintenance to ensure they continue to function properly and safely. In this article, we will provide you with some top tips for maintaining your vacuum glass lifter sucker.

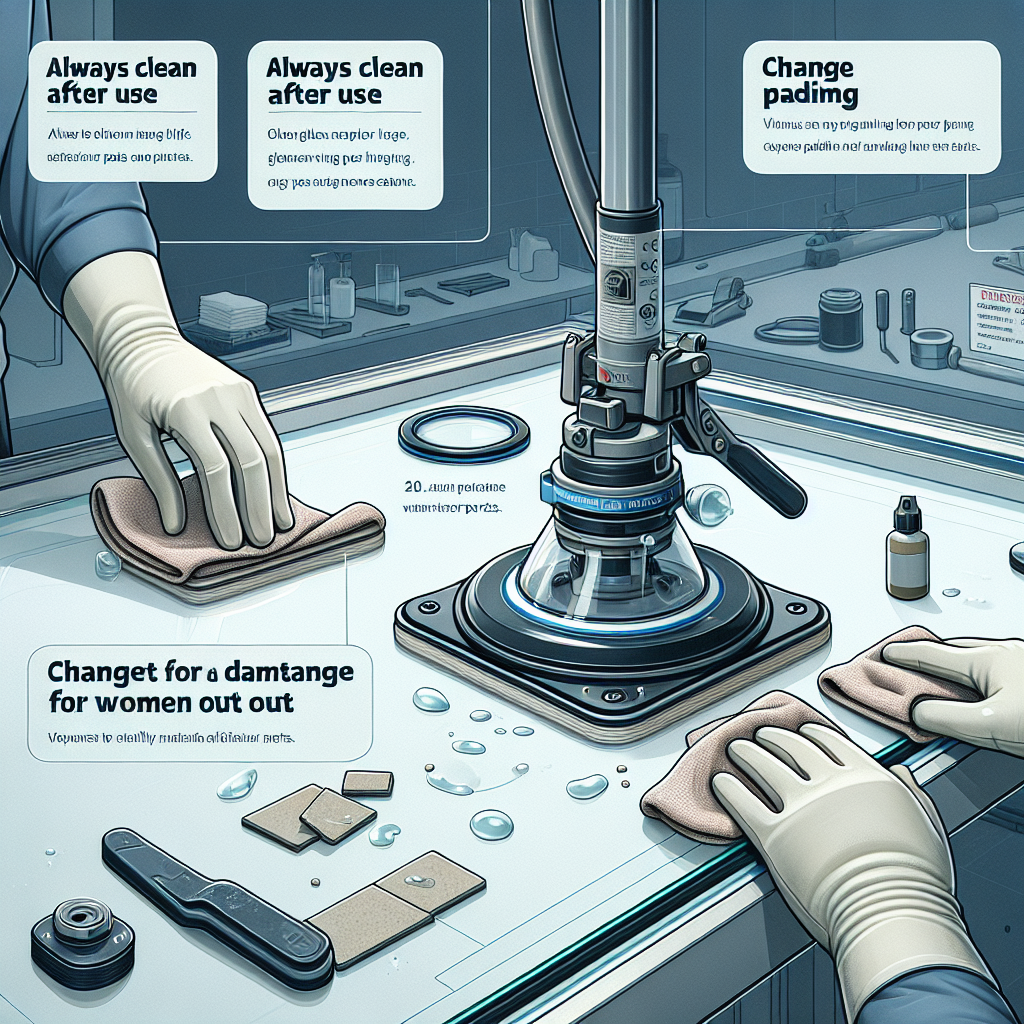

First and foremost, it is crucial to clean your vacuum glass lifter sucker after each use. Glass panels can leave behind residue and debris that can clog the suction cups and affect their performance. To clean the sucker, start by removing any visible dirt or debris with a soft brush or cloth. Then, use a mild detergent and warm water to thoroughly clean the suction cups. Rinse them well and allow them to air dry before storing the lifter sucker.

In addition to regular cleaning, it is important to inspect your vacuum glass lifter sucker for any signs of wear or damage. Check the suction cups for cracks, tears, or any other signs of deterioration. If you notice any damage, it is crucial to replace the suction cups immediately. Using a damaged sucker can compromise the safety of your lifting operations and potentially lead to accidents or injuries.

Furthermore, pay attention to the condition of the vacuum pump. The pump is responsible for creating the suction that holds the glass panel in place. Regularly inspect the pump for any leaks or unusual noises. If you notice any issues, it is recommended to have the pump serviced or replaced by a professional. Neglecting pump maintenance can result in a loss of suction power and make the lifter sucker ineffective.

Another important aspect of maintaining your vacuum glass lifter sucker is storing it properly. After each use, make sure to store the lifter sucker in a clean and dry environment. Avoid exposing it to extreme temperatures or direct sunlight, as this can damage the suction cups and other components. Additionally, store the lifter sucker in a way that prevents any unnecessary pressure or stress on the suction cups.

Regularly inspect the hoses and fittings of your vacuum glass lifter sucker. These components are crucial for the proper functioning of the lifter sucker and should be checked for any signs of wear or damage. Replace any damaged hoses or fittings immediately to ensure the lifter sucker operates safely and efficiently.

Lastly, it is essential to follow the manufacturer’s instructions for your specific vacuum glass lifter sucker model. Different models may have different maintenance requirements, so it is important to familiarize yourself with the guidelines provided by the manufacturer. By following these instructions, you can ensure that your lifter sucker remains in optimal condition and prolong its lifespan.

In conclusion, maintaining your vacuum glass lifter sucker is crucial for its proper functioning and your safety. Regularly clean the suction cups, inspect for damage, and store it properly. Pay attention to the condition of the vacuum pump, hoses, and fittings, and replace any damaged components promptly. By following these top tips, you can ensure that your vacuum glass lifter sucker remains in excellent condition and continues to provide you with reliable performance.

Common Issues and Troubleshooting Tips for Vacuum Glass Lifter Suckers

Vacuum glass lifter suckers are essential tools for lifting and moving heavy glass panels. They provide a secure grip and make the task much easier and safer. However, like any tool, they require regular maintenance to ensure optimal performance and longevity. In this article, we will discuss some common issues that may arise with vacuum glass lifter suckers and provide troubleshooting tips to help you keep your equipment in top shape.

One common issue that users may encounter is a loss of suction power. This can be caused by a variety of factors, such as a damaged or worn-out rubber seal, a clogged filter, or a malfunctioning pump. To troubleshoot this issue, start by inspecting the rubber seal for any signs of wear or damage. If you notice any cracks or tears, it is important to replace the seal as soon as possible. Additionally, check the filter for any debris or blockages and clean or replace it if necessary. If these steps do not resolve the issue, it may be necessary to have the pump inspected and repaired by a professional.

Another issue that users may face is a leaking vacuum lifter sucker. This can be a frustrating problem, as it not only affects the suction power but can also damage the glass panels being lifted. Leaks can occur due to a loose or damaged seal, a cracked or broken glass plate, or a faulty valve. To address this issue, start by checking the seal for any signs of damage or wear and tighten it if necessary. If the seal is in good condition, inspect the glass plate for any cracks or breaks. If you find any, it is crucial to replace the plate immediately. Finally, check the valve for any signs of malfunction and have it repaired or replaced if needed.

One issue that is often overlooked but can have a significant impact on the performance of a vacuum glass lifter sucker is the condition of the vacuum cups. Over time, the cups can become worn out or damaged, resulting in a loss of suction power and stability. To prevent this issue, it is important to regularly inspect the cups for any signs of wear or damage and replace them as needed. Additionally, make sure to clean the cups thoroughly after each use to remove any debris or residue that may affect their performance.

Proper storage and handling of vacuum glass lifter suckers are also crucial for maintaining their performance and longevity. When not in use, it is important to store the equipment in a clean and dry environment to prevent the accumulation of dust and moisture. Additionally, make sure to handle the lifter sucker with care, avoiding any rough or excessive force that may cause damage to the components.

In conclusion, regular maintenance and troubleshooting are essential for keeping your vacuum glass lifter sucker in top shape. By addressing common issues such as loss of suction power, leaks, and worn-out vacuum cups, you can ensure optimal performance and extend the lifespan of your equipment. Remember to inspect and replace damaged components, clean the equipment thoroughly, and store and handle it with care. By following these tips, you can enjoy the benefits of a reliable and efficient vacuum glass lifter sucker for years to come.

Best Practices for Prolonging the Lifespan of Vacuum Glass Lifter Suckers

Top Tips for Maintaining Your Vacuum Glass Lifter Sucker

Vacuum glass lifter suckers are essential tools for professionals in the glass industry. They provide a safe and efficient way to handle large glass panels, reducing the risk of accidents and damage. However, like any tool, vacuum glass lifter suckers require regular maintenance to ensure their longevity and optimal performance. In this article, we will discuss some best practices for prolonging the lifespan of your vacuum glass lifter sucker.

First and foremost, it is crucial to clean your vacuum glass lifter sucker after each use. Glass dust, debris, and other contaminants can accumulate on the suction cups, compromising their ability to create a strong vacuum seal. To clean the suction cups, use a soft cloth or sponge and a mild detergent. Avoid using abrasive cleaners or scrub brushes, as they can damage the surface of the suction cups. Rinse the suction cups thoroughly with clean water and allow them to air dry before storing the lifter sucker.

In addition to regular cleaning, it is essential to inspect your vacuum glass lifter sucker for any signs of wear or damage. Check the suction cups for cracks, tears, or any other visible defects. If you notice any issues, replace the suction cups immediately. Using a damaged suction cup can lead to a weak vacuum seal, increasing the risk of accidents and damage to the glass panels. Regularly inspect the other components of the lifter sucker, such as the handle, pump, and release valve, and ensure they are in good working condition.

Proper storage is another crucial aspect of maintaining your vacuum glass lifter sucker. When not in use, store the lifter sucker in a clean and dry environment. Avoid exposing it to extreme temperatures or direct sunlight, as these can degrade the materials and reduce the lifespan of the suction cups. If possible, store the lifter sucker in its original case or a dedicated storage bag to protect it from dust and other contaminants.

Regularly lubricating the moving parts of your vacuum glass lifter sucker is also essential for its proper functioning. Apply a small amount of silicone lubricant to the pump handle, release valve, and any other moving parts as recommended by the manufacturer. This will help prevent friction and ensure smooth operation. Be sure to wipe off any excess lubricant to avoid attracting dust and debris.

Lastly, it is crucial to follow the manufacturer’s guidelines and recommendations for your specific vacuum glass lifter sucker model. Different models may have different maintenance requirements, so it is essential to familiarize yourself with the user manual. The manufacturer may provide specific instructions on cleaning, inspection, lubrication, and storage. Following these guidelines will help ensure the longevity and optimal performance of your vacuum glass lifter sucker.

In conclusion, maintaining your vacuum glass lifter sucker is essential for its longevity and optimal performance. Regular cleaning, inspection, and lubrication are key to ensuring a strong vacuum seal and reducing the risk of accidents and damage. Proper storage and following the manufacturer’s guidelines are also crucial for prolonging the lifespan of your lifter sucker. By implementing these best practices, you can enjoy the benefits of your vacuum glass lifter sucker for years to come.