Increased Efficiency and Productivity in Construction with Vacuum Glass Lifters

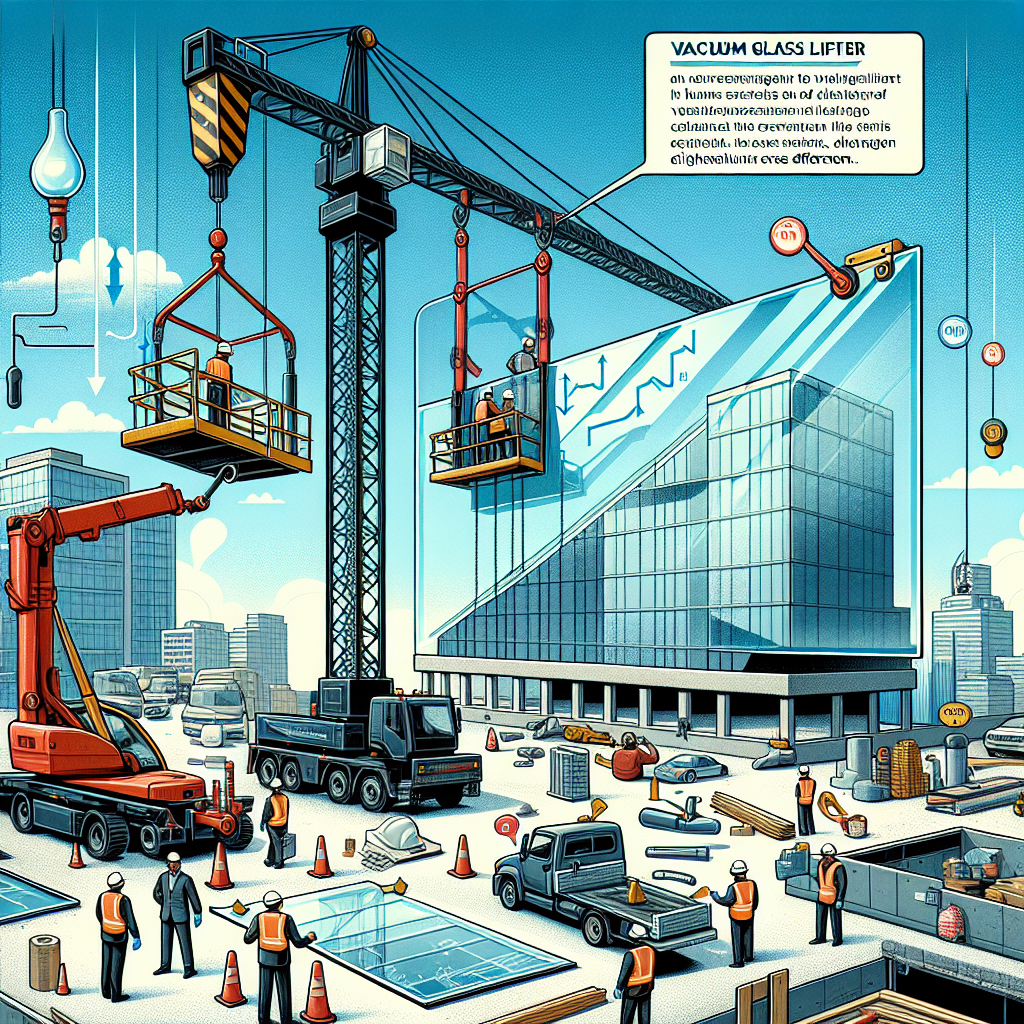

The construction industry has seen significant advancements in technology over the years, and one such innovation that has revolutionized modern construction techniques is the vacuum glass lifter. These powerful machines have had a profound impact on the efficiency and productivity of construction projects, making them an indispensable tool for contractors and builders.

One of the key benefits of vacuum glass lifters is their ability to handle heavy loads with ease. Traditional methods of lifting and installing glass panels required a team of workers and specialized equipment, which was not only time-consuming but also posed a risk to the safety of the workers. With vacuum glass lifters, a single operator can effortlessly lift and maneuver large glass panels, reducing the need for additional manpower and minimizing the risk of accidents.

Furthermore, vacuum glass lifters are designed to be versatile and adaptable to different construction scenarios. They can be easily attached to cranes, forklifts, or other lifting equipment, allowing for seamless integration into existing construction processes. This flexibility enables contractors to use vacuum glass lifters in a wide range of projects, from high-rise buildings to residential homes, without the need for extensive modifications or additional equipment.

In addition to their lifting capabilities, vacuum glass lifters also contribute to increased efficiency in construction projects. The speed at which glass panels can be installed using these machines is unparalleled. With traditional methods, the installation of glass panels was a time-consuming process that required careful handling and precise alignment. Vacuum glass lifters eliminate these challenges by providing a secure grip on the glass panels, allowing for quick and accurate placement. This not only saves time but also reduces the overall construction timeline, enabling contractors to complete projects faster and more efficiently.

Moreover, the use of vacuum glass lifters has a positive impact on the quality of construction. The secure grip provided by these machines ensures that glass panels are installed with precision and accuracy, minimizing the risk of breakage or damage. This level of precision is crucial in achieving a high-quality finish, especially in architectural projects where aesthetics play a significant role. By eliminating human error and providing a reliable lifting solution, vacuum glass lifters contribute to the overall quality and durability of construction projects.

Another advantage of vacuum glass lifters is their ability to enhance worker safety. Traditional methods of glass installation often required workers to manually handle heavy and fragile glass panels, putting them at risk of injury. Vacuum glass lifters eliminate the need for manual lifting, reducing the strain on workers’ bodies and minimizing the risk of accidents. This not only improves the safety of the workers but also boosts their morale and productivity, as they can focus on other critical tasks without the fear of injury.

In conclusion, vacuum glass lifters have had a significant impact on modern construction techniques, particularly in terms of increased efficiency and productivity. These machines have revolutionized the way glass panels are handled and installed, providing a safer and more efficient alternative to traditional methods. With their ability to handle heavy loads, adaptability to different construction scenarios, and contribution to improved quality and worker safety, vacuum glass lifters have become an indispensable tool in the construction industry. As technology continues to advance, it is likely that vacuum glass lifters will continue to evolve, further enhancing the efficiency and productivity of construction projects.

Enhancing Safety Measures in Construction through Vacuum Glass Lifters

The construction industry has seen significant advancements in recent years, with new technologies and techniques revolutionizing the way buildings are designed and constructed. One such innovation that has had a profound impact on modern construction techniques is the vacuum glass lifter. These devices have become an essential tool for enhancing safety measures in construction, particularly when it comes to handling and installing glass panels.

Glass has become an increasingly popular material in modern architecture, thanks to its aesthetic appeal and ability to create a sense of openness and transparency. However, working with glass poses unique challenges, as it is fragile and can be difficult to handle. Traditional methods of lifting and installing glass panels often involved manual labor, which not only increased the risk of accidents but also slowed down the construction process.

Vacuum glass lifters have emerged as a game-changer in the construction industry, offering a safe and efficient solution for handling glass panels. These devices use suction cups to create a vacuum seal with the glass, allowing it to be lifted and moved without the need for physical contact. This eliminates the risk of glass panels slipping or shattering during transportation, significantly reducing the likelihood of accidents and injuries on construction sites.

One of the key advantages of vacuum glass lifters is their ability to handle heavy and oversized glass panels with ease. In the past, installing large glass panels required multiple workers and specialized equipment. With vacuum glass lifters, a single operator can safely lift and position even the heaviest glass panels, saving time and manpower. This not only improves efficiency but also reduces labor costs, making construction projects more cost-effective.

Furthermore, vacuum glass lifters offer precise control and maneuverability, allowing for accurate placement of glass panels. This is particularly important in architectural designs that require precise alignment and positioning of glass elements. The ability to make micro-adjustments ensures that the final installation is flawless, enhancing the overall aesthetic appeal of the building.

In addition to their safety and efficiency benefits, vacuum glass lifters also contribute to sustainability in construction. By minimizing the risk of glass breakage, these devices reduce waste and the need for replacement panels. This not only saves money but also reduces the environmental impact of construction projects. Furthermore, the use of vacuum glass lifters eliminates the need for excessive scaffolding or other temporary structures, reducing material consumption and waste generation.

It is worth noting that vacuum glass lifters are not limited to new construction projects. They can also be used for renovation and retrofitting projects, where existing glass panels need to be removed and replaced. The ability to safely handle and transport glass panels makes these devices invaluable in preserving the integrity of historical buildings or upgrading outdated structures.

In conclusion, vacuum glass lifters have revolutionized modern construction techniques by enhancing safety measures and improving efficiency. These devices offer a safe and efficient solution for handling and installing glass panels, reducing the risk of accidents and injuries on construction sites. Their ability to handle heavy and oversized glass panels, along with precise control and maneuverability, makes them an essential tool in modern architecture. Furthermore, vacuum glass lifters contribute to sustainability in construction by minimizing waste and reducing the environmental impact of projects. Whether it is a new construction project or a renovation, vacuum glass lifters have become an indispensable tool for the construction industry.

Sustainable Construction Practices with Vacuum Glass Lifters

The Impact of Vacuum Glass Lifters on Modern Construction Techniques

Sustainable Construction Practices with Vacuum Glass Lifters

In recent years, the construction industry has seen a significant shift towards sustainable practices. With the growing concern for the environment and the need to reduce carbon emissions, construction companies are actively seeking ways to minimize their ecological footprint. One such innovation that has gained popularity is the use of vacuum glass lifters in construction projects.

Vacuum glass lifters are specialized tools designed to lift and transport large glass panels with ease. They consist of a vacuum pump, suction cups, and a control system that allows for precise positioning. These lifters are typically attached to cranes or other heavy machinery, enabling workers to handle glass panels safely and efficiently.

One of the key advantages of vacuum glass lifters is their ability to reduce the risk of accidents and injuries. In traditional construction methods, workers often had to manually lift and carry heavy glass panels, which posed a significant safety hazard. With vacuum glass lifters, the risk of dropping or mishandling glass panels is greatly minimized, ensuring the safety of workers and preventing costly accidents.

Furthermore, vacuum glass lifters contribute to sustainable construction practices by reducing material waste. In the past, when glass panels were damaged during installation, they had to be discarded and replaced, resulting in significant waste. However, with the use of vacuum glass lifters, damaged panels can be easily removed and replaced without causing further damage. This not only reduces waste but also saves time and resources, making construction projects more efficient and cost-effective.

Another significant impact of vacuum glass lifters on modern construction techniques is their ability to enhance energy efficiency. Glass is a popular material in modern architecture due to its aesthetic appeal and ability to allow natural light into buildings. However, traditional installation methods often compromised the energy efficiency of glass panels, leading to increased heating and cooling costs. Vacuum glass lifters address this issue by ensuring precise and secure installation, minimizing gaps and air leakage. This, in turn, improves the energy efficiency of buildings, reducing the reliance on artificial lighting and HVAC systems.

Moreover, vacuum glass lifters enable the construction of larger and more complex glass structures. In the past, the size and weight limitations of glass panels restricted the design possibilities for architects. However, with the use of vacuum glass lifters, larger and heavier glass panels can be safely transported and installed, allowing for more innovative and visually striking architectural designs. This has revolutionized the construction industry, enabling the creation of iconic structures that were once deemed impossible.

In conclusion, vacuum glass lifters have had a profound impact on modern construction techniques. They have not only improved safety standards but also contributed to sustainable construction practices. By reducing accidents, minimizing waste, enhancing energy efficiency, and enabling innovative designs, vacuum glass lifters have become an essential tool in the construction industry. As the demand for sustainable construction practices continues to grow, it is likely that vacuum glass lifters will become even more prevalent in future construction projects.