Benefits of Using Vacuum Glass Lifter Suckers in Commercial Applications

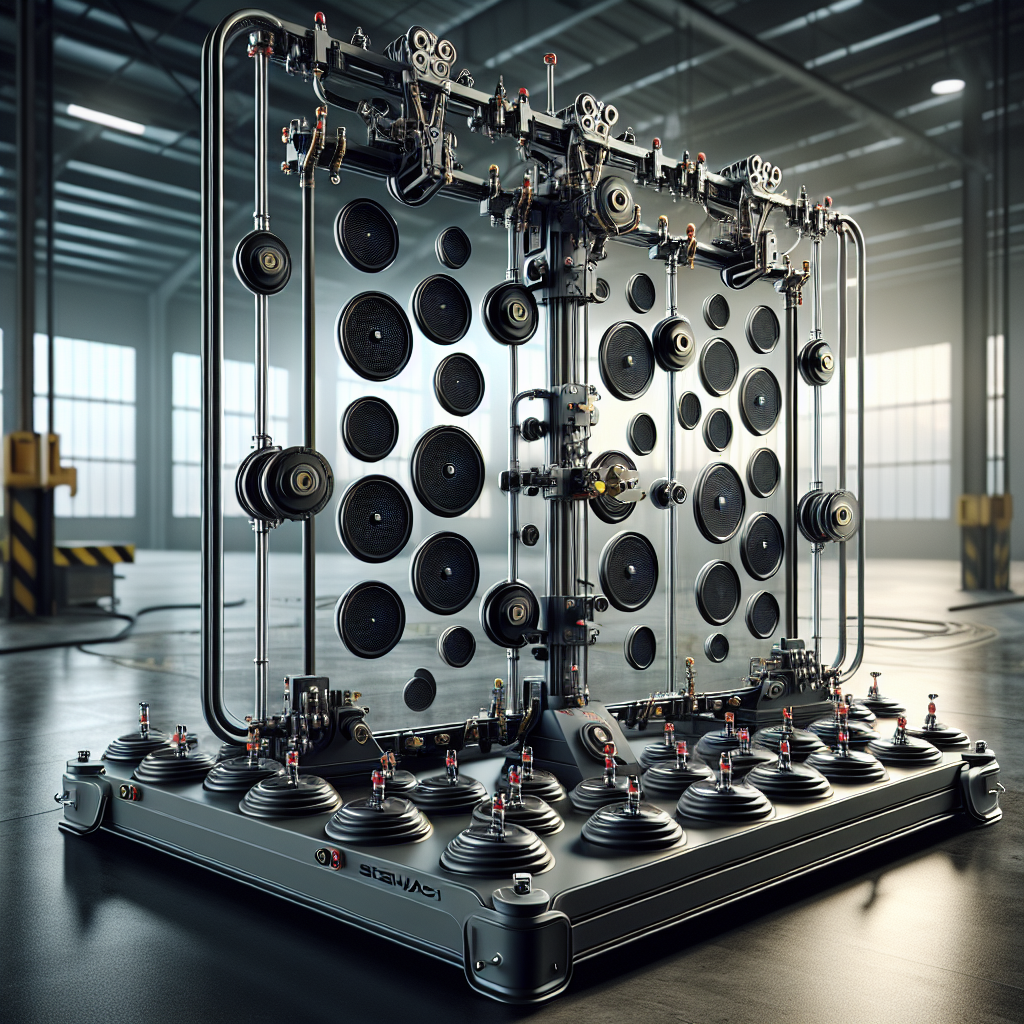

The use of vacuum glass lifter suckers in commercial applications has become increasingly popular in recent years. These innovative devices offer a range of benefits that make them an essential tool for any business involved in glass installation or handling.

One of the key advantages of using vacuum glass lifter suckers is their ability to lift heavy glass panels with ease. Traditional methods of lifting glass often require multiple workers and can be time-consuming and physically demanding. However, with a vacuum glass lifter sucker, a single operator can effortlessly lift and maneuver even the heaviest of glass panels. This not only saves time but also reduces the risk of injury to workers.

Another benefit of using vacuum glass lifter suckers is their versatility. These devices can be used to lift glass panels of various shapes and sizes, making them suitable for a wide range of commercial applications. Whether you need to install large windows in a high-rise building or handle delicate glass artwork in a museum, a vacuum glass lifter sucker can provide the necessary support and stability.

In addition to their lifting capabilities, vacuum glass lifter suckers also offer excellent precision and control. These devices are equipped with adjustable suction cups that can be easily positioned to match the shape and size of the glass panel. This ensures a secure grip and minimizes the risk of slippage or damage during lifting and transportation. The ability to precisely control the suction force also allows for delicate handling of fragile glass, further reducing the risk of breakage.

Furthermore, vacuum glass lifter suckers are designed with safety in mind. These devices are equipped with multiple safety features, such as audible alarms and visual indicators, to alert the operator of any potential issues. They also have built-in backup systems that prevent sudden drops in case of power failure. This ensures that both the glass panels and the workers are protected at all times.

Another advantage of using vacuum glass lifter suckers is their efficiency. These devices are designed to streamline the glass installation process, allowing for faster and more efficient work. With a vacuum glass lifter sucker, a single operator can complete tasks that would typically require multiple workers, saving both time and labor costs. This increased efficiency also translates into higher productivity and faster project completion times.

Lastly, vacuum glass lifter suckers are a cost-effective solution for commercial applications. While the initial investment may seem significant, the long-term benefits outweigh the upfront costs. These devices are durable and require minimal maintenance, reducing the need for frequent repairs or replacements. Additionally, the time and labor savings achieved through the use of vacuum glass lifter suckers can result in significant cost savings over time.

In conclusion, the use of vacuum glass lifter suckers in commercial applications offers numerous benefits. From their ability to lift heavy glass panels with ease to their versatility, precision, and safety features, these devices are an invaluable tool for any business involved in glass installation or handling. Their efficiency and cost-effectiveness further make them a worthwhile investment. By incorporating vacuum glass lifter suckers into their operations, businesses can improve productivity, reduce labor costs, and ensure the safe and efficient handling of glass panels.

Top Features to Consider When Choosing a Vacuum Glass Lifter Sucker for Commercial Use

When it comes to commercial applications that involve lifting and moving heavy glass panels, a vacuum glass lifter sucker is an essential tool. These devices use suction to securely grip onto glass surfaces, allowing for safe and efficient handling. However, with so many options available on the market, it can be challenging to determine which vacuum glass lifter sucker is the best choice for your specific needs. In this article, we will discuss the top features to consider when choosing a vacuum glass lifter sucker for commercial use.

One of the most important features to look for in a vacuum glass lifter sucker is its lifting capacity. Commercial applications often involve large and heavy glass panels, so it is crucial to select a lifter sucker that can handle the weight. The lifting capacity is typically measured in kilograms or pounds, and it is essential to choose a lifter sucker that can comfortably lift the heaviest glass panels you work with.

Another important feature to consider is the number and arrangement of suction cups on the lifter sucker. The more suction cups a lifter sucker has, the more evenly distributed the weight of the glass panel will be. This helps to prevent any imbalances or instability during lifting, ensuring a safer and more secure grip. Additionally, some lifters have adjustable suction cup arrangements, allowing for greater flexibility in handling different sizes and shapes of glass panels.

The type of suction cup material is also a crucial factor to consider. The suction cups should be made from a durable and long-lasting material that can withstand the demands of commercial use. Additionally, the material should be non-marking to prevent any damage or scratches to the glass surface. Silicone is a popular choice for suction cup material due to its excellent grip and non-marking properties.

Furthermore, it is essential to consider the power source of the vacuum glass lifter sucker. Some lifters are powered by electricity, while others are battery-operated. Electric-powered lifters typically provide a more consistent and reliable suction force, making them suitable for heavy-duty applications. On the other hand, battery-operated lifters offer greater mobility and flexibility, as they are not limited by the availability of power outlets. The choice between electric and battery-powered lifters depends on the specific requirements of your commercial application.

Additionally, it is worth considering the safety features of the vacuum glass lifter sucker. Look for lifters that have built-in safety mechanisms, such as audible alarms or visual indicators, to alert the operator in case of any issues or malfunctions. Some lifters also have automatic release systems that prevent accidental drops or releases of the glass panel. These safety features are crucial for preventing accidents and ensuring the well-being of the operators and the integrity of the glass panels.

In conclusion, choosing the right vacuum glass lifter sucker for commercial applications requires careful consideration of several key features. These include the lifting capacity, the number and arrangement of suction cups, the suction cup material, the power source, and the safety features. By selecting a lifter sucker that meets your specific needs and requirements, you can ensure safe and efficient handling of heavy glass panels in your commercial operations.

How to Properly Maintain and Extend the Lifespan of Vacuum Glass Lifter Suckers in Commercial Settings

Vacuum glass lifter suckers are essential tools in commercial settings for lifting and moving heavy glass panels. These powerful devices use suction to create a vacuum seal, allowing them to securely grip onto glass surfaces. However, like any tool, vacuum glass lifter suckers require proper maintenance to ensure their longevity and optimal performance. In this article, we will discuss some essential tips on how to properly maintain and extend the lifespan of vacuum glass lifter suckers in commercial settings.

First and foremost, it is crucial to regularly inspect the vacuum glass lifter suckers for any signs of wear and tear. Check the suction cups for cracks, tears, or any other damage that may compromise their ability to create a strong vacuum seal. If you notice any issues, it is important to replace the damaged suction cups immediately to avoid any accidents or damage to the glass panels.

Cleaning the suction cups is another vital aspect of maintaining vacuum glass lifter suckers. After each use, make sure to remove any dirt, debris, or adhesive residue from the suction cups. This can be done by wiping them with a clean cloth or using a mild detergent and water solution. Avoid using harsh chemicals or abrasive materials that could damage the suction cups. Additionally, ensure that the suction cups are completely dry before storing them to prevent the growth of mold or mildew.

Proper storage is also essential for extending the lifespan of vacuum glass lifter suckers. Store them in a clean and dry environment, away from direct sunlight or extreme temperatures. Avoid placing heavy objects on top of the suction cups, as this can cause deformation or damage. It is also advisable to store the vacuum glass lifter suckers in their original packaging or a dedicated storage case to protect them from dust and other contaminants.

Regularly inspecting and maintaining the vacuum pump is equally important. The vacuum pump is responsible for creating the suction force that holds the glass panels in place. Check the pump for any signs of leakage, unusual noises, or decreased suction power. If you notice any issues, it is crucial to have the pump serviced or repaired by a qualified technician. Neglecting the maintenance of the vacuum pump can lead to decreased performance and potential safety hazards.

In addition to regular maintenance, it is essential to follow the manufacturer’s guidelines and recommendations for the specific model of vacuum glass lifter suckers you are using. Each model may have unique maintenance requirements, so it is crucial to familiarize yourself with the user manual and adhere to the suggested maintenance schedule.

In conclusion, proper maintenance is crucial for extending the lifespan and ensuring the optimal performance of vacuum glass lifter suckers in commercial settings. Regularly inspecting the suction cups, cleaning them properly, storing them correctly, and maintaining the vacuum pump are all essential steps in maintaining these powerful tools. By following these tips and adhering to the manufacturer’s guidelines, you can maximize the lifespan of your vacuum glass lifter suckers and ensure their safe and efficient operation in your commercial applications.