Increased Efficiency and Productivity in Large-Scale Projects with Vacuum Glass Lifters

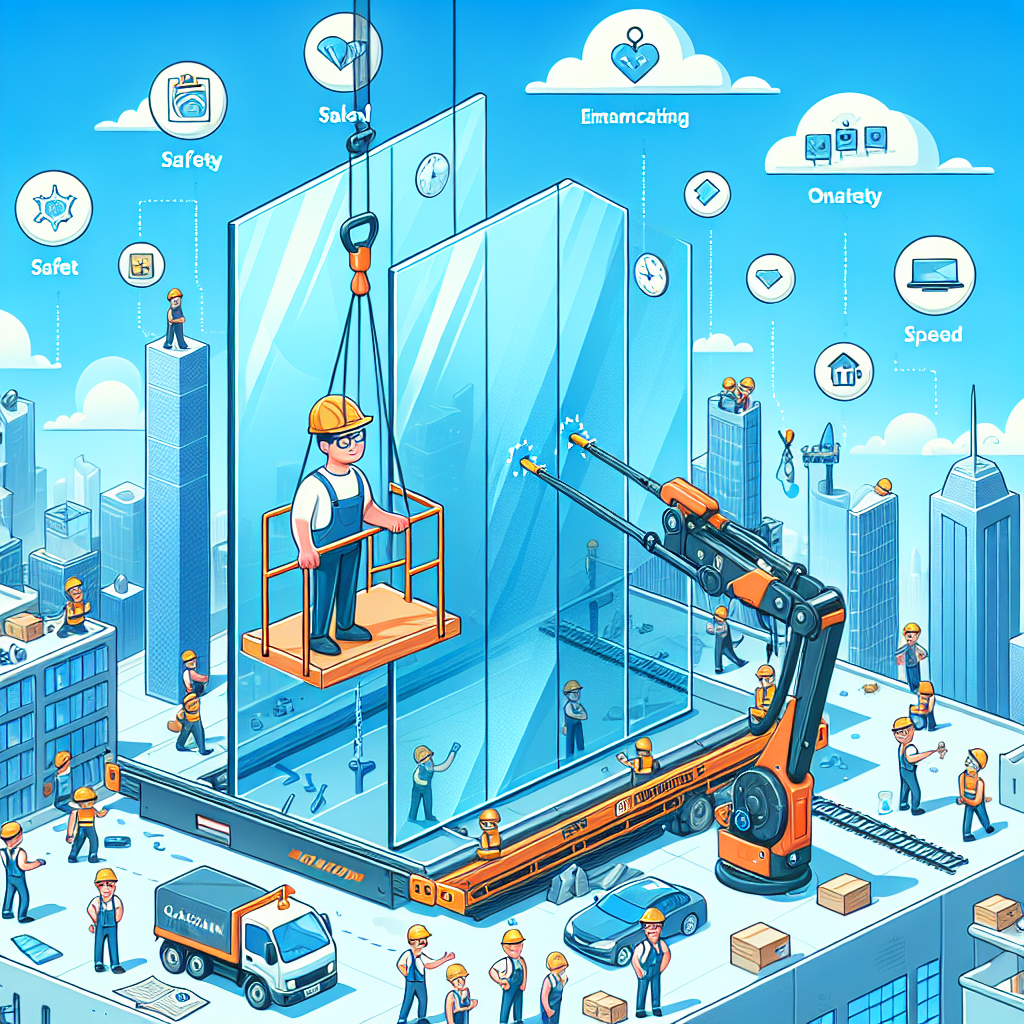

The use of vacuum glass lifters in large-scale projects has become increasingly popular in recent years. These innovative machines offer a range of benefits that can greatly improve efficiency and productivity on construction sites. In this article, we will explore some of the key advantages of using a vacuum glass lifter in large-scale projects.

One of the main benefits of using a vacuum glass lifter is the increased efficiency it provides. Traditional methods of lifting and moving glass panels often require multiple workers and specialized equipment. This can be time-consuming and labor-intensive, resulting in delays and increased costs. However, with a vacuum glass lifter, a single operator can easily lift and maneuver large glass panels with minimal effort. This not only saves time but also reduces the need for additional manpower, allowing workers to focus on other tasks.

Another advantage of using a vacuum glass lifter is the improved safety it offers. Lifting and moving heavy glass panels manually can be hazardous, posing a risk of injury to workers. Vacuum glass lifters eliminate this risk by securely gripping the glass panels using suction cups. This ensures a firm hold on the glass, preventing it from slipping or falling during transportation. Additionally, many vacuum glass lifters are equipped with safety features such as alarms and warning lights, further enhancing worker safety on the construction site.

In addition to increased efficiency and improved safety, vacuum glass lifters also contribute to enhanced productivity in large-scale projects. These machines are designed to handle a wide range of glass panel sizes and weights, making them versatile and adaptable to different project requirements. With their ability to lift and transport glass panels quickly and easily, vacuum glass lifters enable workers to complete tasks more efficiently, allowing for faster project completion times. This not only saves time but also reduces overall project costs.

Furthermore, vacuum glass lifters can be used in various construction applications, including the installation of windows, curtain walls, and glass facades. Their versatility makes them a valuable asset in large-scale projects where glass panels are a common feature. By using a vacuum glass lifter, construction companies can streamline their operations and achieve higher levels of productivity.

In conclusion, the use of vacuum glass lifters in large-scale projects offers numerous benefits. These machines increase efficiency by allowing a single operator to lift and maneuver large glass panels with ease. They also improve safety by securely gripping the glass, reducing the risk of accidents and injuries. Additionally, vacuum glass lifters contribute to enhanced productivity by enabling workers to complete tasks more quickly and efficiently. Their versatility and adaptability make them a valuable asset in construction projects that involve the installation of glass panels. Overall, the use of vacuum glass lifters in large-scale projects is a wise investment that can greatly improve efficiency and productivity on construction sites.

Enhanced Safety Measures and Risk Reduction with Vacuum Glass Lifters in Large-Scale Projects

The use of vacuum glass lifters in large-scale projects offers numerous benefits, particularly in terms of enhanced safety measures and risk reduction. These innovative devices have revolutionized the way glass panels are handled and installed, providing a safer and more efficient alternative to traditional methods.

One of the primary advantages of using a vacuum glass lifter is the significant reduction in the risk of accidents and injuries. In large-scale projects, the installation of glass panels can be a hazardous task, as they are heavy and fragile. Traditional methods often involve manual lifting, which can lead to strain and potential accidents. However, with a vacuum glass lifter, the panels can be securely lifted and moved without the need for physical exertion. This eliminates the risk of strain-related injuries and ensures the safety of workers.

Furthermore, vacuum glass lifters are designed to provide a secure grip on glass panels, minimizing the risk of dropping or shattering. These devices utilize suction cups that create a vacuum seal, firmly holding the glass in place. This eliminates the need for workers to physically hold the panels, reducing the chances of accidental drops and breakages. The secure grip provided by vacuum glass lifters not only protects the glass panels but also prevents potential injuries caused by shattered glass.

In addition to enhanced safety measures, the use of vacuum glass lifters in large-scale projects also offers increased efficiency and productivity. These devices are designed to handle multiple glass panels simultaneously, allowing for faster installation times. With traditional methods, workers would typically need to manually lift and position each panel individually, which can be time-consuming and labor-intensive. However, with a vacuum glass lifter, multiple panels can be lifted and moved at once, significantly reducing installation time and increasing productivity.

Moreover, vacuum glass lifters are versatile and can be used in various large-scale projects. Whether it is the installation of glass facades in high-rise buildings or the construction of large windows in commercial structures, these devices can handle a wide range of glass panel sizes and weights. This versatility makes vacuum glass lifters a valuable asset in any large-scale project, as they can be easily adapted to meet specific requirements.

Another advantage of using vacuum glass lifters is the reduced need for additional manpower. With traditional methods, the installation of glass panels often requires a team of workers to handle the lifting and positioning. However, with a vacuum glass lifter, the need for additional manpower is significantly reduced. This not only saves costs but also allows for a more streamlined and efficient workflow.

In conclusion, the use of vacuum glass lifters in large-scale projects offers numerous benefits, particularly in terms of enhanced safety measures and risk reduction. These devices provide a secure grip on glass panels, minimizing the risk of accidents and injuries. Additionally, they offer increased efficiency and productivity by allowing for faster installation times and reducing the need for additional manpower. With their versatility and ability to handle various glass panel sizes and weights, vacuum glass lifters have become an essential tool in the construction industry. By incorporating these innovative devices into large-scale projects, contractors can ensure the safety of their workers while maximizing productivity and efficiency.

Cost Savings and Time Optimization through the Use of Vacuum Glass Lifters in Large-Scale Projects

The use of vacuum glass lifters in large-scale projects offers numerous benefits, including cost savings and time optimization. These innovative tools have revolutionized the way glass panels are handled and installed, making them an essential asset for any construction or renovation project.

One of the primary advantages of using a vacuum glass lifter is the significant cost savings it provides. Traditional methods of glass installation often require a large workforce, with multiple workers needed to lift and maneuver heavy glass panels. This not only increases labor costs but also poses a risk to worker safety. In contrast, a vacuum glass lifter can be operated by a single person, reducing the need for additional labor and minimizing the associated costs.

Furthermore, the use of a vacuum glass lifter eliminates the need for expensive and time-consuming scaffolding or cranes. These traditional methods often require extensive setup and dismantling, adding to the overall project timeline and budget. With a vacuum glass lifter, glass panels can be easily lifted and maneuvered into place, eliminating the need for complex equipment and reducing installation time.

In addition to cost savings, the use of a vacuum glass lifter also optimizes project timelines. The efficiency and ease of use of these tools allow for faster glass installation, reducing overall project duration. This is particularly beneficial in large-scale projects where time is of the essence. By streamlining the glass installation process, project managers can ensure that deadlines are met and that the project progresses smoothly.

Moreover, the use of a vacuum glass lifter enhances worker safety. Traditional methods of glass installation often involve manual lifting and maneuvering, which can lead to accidents and injuries. Vacuum glass lifters eliminate the need for workers to physically handle heavy glass panels, reducing the risk of strain or accidents. This not only protects the well-being of workers but also minimizes the potential for costly liability claims.

Another advantage of using a vacuum glass lifter is its versatility. These tools can be used for a wide range of glass panel sizes and shapes, making them suitable for various project requirements. Whether it is a large-scale commercial building or a residential renovation, a vacuum glass lifter can handle the task efficiently and effectively.

Furthermore, vacuum glass lifters are designed with precision and control in mind. They offer adjustable suction cups and lifting mechanisms, allowing for precise positioning and alignment of glass panels. This ensures a seamless and accurate installation, enhancing the overall aesthetic appeal of the project.

In conclusion, the use of a vacuum glass lifter in large-scale projects offers significant benefits in terms of cost savings and time optimization. By reducing labor costs, eliminating the need for complex equipment, and streamlining the installation process, these tools provide a cost-effective and efficient solution for glass panel handling and installation. Additionally, the enhanced worker safety, versatility, and precision offered by vacuum glass lifters make them an invaluable asset in any construction or renovation project. With their numerous advantages, it is clear that vacuum glass lifters are a game-changer in the industry, revolutionizing the way glass panels are handled and installed.