Increased Efficiency and Productivity with Glass Lifter Suckers

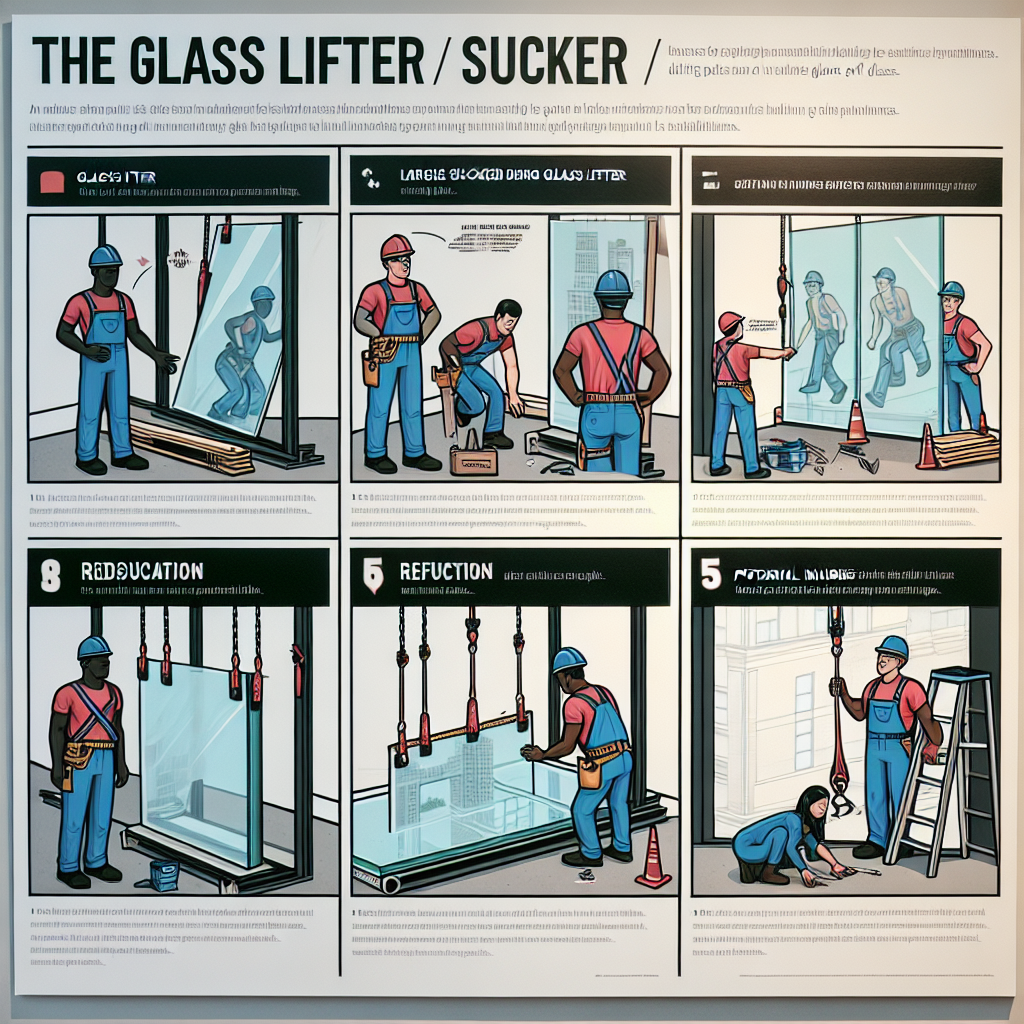

The use of glass lifter suckers for large installations offers numerous benefits, particularly in terms of increased efficiency and productivity. These innovative tools have revolutionized the way glass is handled and installed, making it easier and safer for workers to complete their tasks.

One of the primary advantages of using a glass lifter sucker is the significant increase in efficiency it provides. Traditional methods of lifting and installing glass involve multiple workers and cumbersome equipment. This not only slows down the installation process but also increases the risk of accidents and damage to the glass. With a glass lifter sucker, however, a single worker can easily lift and maneuver large glass panels, eliminating the need for additional manpower. This streamlined approach allows for faster installation times, ultimately saving both time and money.

In addition to increased efficiency, glass lifter suckers also enhance productivity on large installations. These tools are designed to securely grip glass panels, providing a stable and reliable lifting mechanism. This eliminates the need for workers to manually hold and support the glass, freeing up their hands to focus on other tasks. With the ability to lift and transport glass panels effortlessly, workers can complete installations more quickly and effectively. This not only increases productivity but also reduces the physical strain on workers, leading to improved overall job satisfaction.

Furthermore, the use of glass lifter suckers significantly reduces the risk of accidents and damage during the installation process. Traditional methods of lifting and moving glass panels often involve precarious balancing acts and the potential for slips and falls. This not only endangers the safety of workers but also puts the glass at risk of being shattered or damaged. Glass lifter suckers, on the other hand, provide a secure and stable grip on the glass, minimizing the chances of accidents and breakages. This not only ensures the safety of workers but also protects the valuable glass panels from costly damage.

Another advantage of using glass lifter suckers is their versatility. These tools are designed to handle a wide range of glass sizes and weights, making them suitable for various installation projects. Whether it’s large windows, glass facades, or even glass partitions, a glass lifter sucker can easily handle the task. This versatility eliminates the need for multiple tools and equipment, simplifying the installation process and reducing costs.

In conclusion, the use of glass lifter suckers for large installations offers numerous benefits, particularly in terms of increased efficiency and productivity. These tools streamline the installation process, allowing for faster completion times and saving both time and money. Additionally, glass lifter suckers enhance productivity by providing a secure and reliable lifting mechanism, freeing up workers’ hands to focus on other tasks. Furthermore, these tools significantly reduce the risk of accidents and damage, ensuring the safety of workers and protecting valuable glass panels. With their versatility and ease of use, glass lifter suckers are a valuable asset for any large installation project.

Enhanced Safety Measures and Risk Reduction in Large Installations with Glass Lifter Suckers

The installation of large glass panels can be a challenging and risky task. The sheer size and weight of these panels make them difficult to handle and maneuver. However, with the use of a glass lifter sucker, these challenges can be overcome, and the installation process can be made much safer and more efficient.

One of the primary benefits of using a glass lifter sucker is the enhanced safety measures it provides. Traditional methods of lifting and installing large glass panels often involve the use of ropes, pulleys, and manual labor. These methods can be dangerous and put workers at risk of injury. Glass lifter suckers, on the other hand, are specifically designed to lift and transport glass panels safely and securely.

These devices are equipped with powerful suction cups that create a vacuum seal between the lifter and the glass panel. This vacuum seal ensures that the glass panel remains firmly attached to the lifter throughout the installation process. This eliminates the risk of the panel slipping or falling, which could cause serious injury or damage. Additionally, glass lifter suckers are often equipped with safety features such as alarms and indicators that alert users if the vacuum seal is compromised.

In addition to enhanced safety measures, the use of a glass lifter sucker can also significantly reduce the risk of damage to the glass panels during installation. Traditional methods of lifting and moving glass panels often involve a high degree of manual handling, which increases the risk of accidental drops or collisions. Glass lifter suckers, on the other hand, provide a secure and stable grip on the glass panel, minimizing the risk of damage.

Furthermore, glass lifter suckers are designed to distribute the weight of the glass panel evenly, reducing the strain on individual workers. This not only reduces the risk of injury but also allows for more precise and controlled movements during the installation process. The ability to maneuver the glass panel with ease and precision is particularly important when working in tight or confined spaces.

Another advantage of using a glass lifter sucker is the increased efficiency it brings to the installation process. Traditional methods of lifting and moving glass panels often require multiple workers and a significant amount of time and effort. Glass lifter suckers, on the other hand, can be operated by a single person and significantly reduce the time and effort required for installation.

The ease of use and maneuverability of glass lifter suckers allow for faster and more efficient installation, saving both time and money. Additionally, the ability to lift and transport glass panels with precision and control allows for more accurate and seamless installations, resulting in a higher quality finished product.

In conclusion, the use of a glass lifter sucker for large installations offers numerous benefits. Enhanced safety measures, reduced risk of damage, increased efficiency, and improved overall quality are just a few of the advantages that these devices provide. By investing in a glass lifter sucker, companies can ensure the safety of their workers, minimize the risk of damage to glass panels, and streamline the installation process.

Cost Savings and Time Optimization through the Use of Glass Lifter Suckers for Large Installations

The installation of large glass panels can be a challenging and time-consuming task. It requires a great deal of manpower and specialized equipment to ensure that the glass is safely and securely placed in position. One tool that has proven to be invaluable in this process is the glass lifter sucker. This device, also known as a vacuum lifter, is designed to lift and transport large glass panels with ease and efficiency.

One of the primary benefits of using a glass lifter sucker for large installations is the cost savings it offers. Traditionally, the installation of large glass panels required a team of workers to manually lift and position the glass. This not only required a significant amount of manpower but also increased the risk of accidents and injuries. By using a glass lifter sucker, the need for multiple workers is eliminated, reducing labor costs and minimizing the risk of workplace accidents.

In addition to cost savings, the use of a glass lifter sucker also optimizes time during the installation process. The device is designed to securely grip the glass panel, allowing it to be lifted and transported quickly and efficiently. This eliminates the need for workers to spend excessive amounts of time manually maneuvering the glass into position. With a glass lifter sucker, large glass panels can be installed in a fraction of the time it would take using traditional methods.

Furthermore, the use of a glass lifter sucker ensures the safety of both the workers and the glass panels themselves. The device is equipped with powerful suction cups that create a strong vacuum seal, securely holding the glass in place during transport. This eliminates the risk of the glass slipping or falling, which could result in damage to the glass or injury to the workers. The secure grip provided by the glass lifter sucker gives workers peace of mind, allowing them to focus on the task at hand without worrying about accidents or mishaps.

Another advantage of using a glass lifter sucker is its versatility. These devices are designed to handle a wide range of glass panel sizes and weights, making them suitable for various installation projects. Whether it’s a small window or a large glass facade, a glass lifter sucker can easily accommodate the size and weight of the glass panel. This versatility makes the device a valuable tool for contractors and installers who work on a variety of projects.

In conclusion, the use of a glass lifter sucker for large installations offers numerous benefits. It provides cost savings by reducing the need for excessive manpower, optimizes time by speeding up the installation process, and ensures the safety of both workers and glass panels. Additionally, the device’s versatility makes it suitable for a wide range of installation projects. By investing in a glass lifter sucker, contractors and installers can streamline their operations, increase efficiency, and achieve superior results in their glass installation projects.