Increased Efficiency and Productivity in Construction with Vacuum Glass Lifters

The construction industry is constantly evolving, with new technologies and tools being developed to improve efficiency and productivity. One such tool that has gained popularity in recent years is the vacuum glass lifter. This innovative device has revolutionized the way glass panels are handled and installed in construction projects. In this article, we will explore the advantages of using a vacuum glass lifter in construction, focusing on the increased efficiency and productivity it brings to the industry.

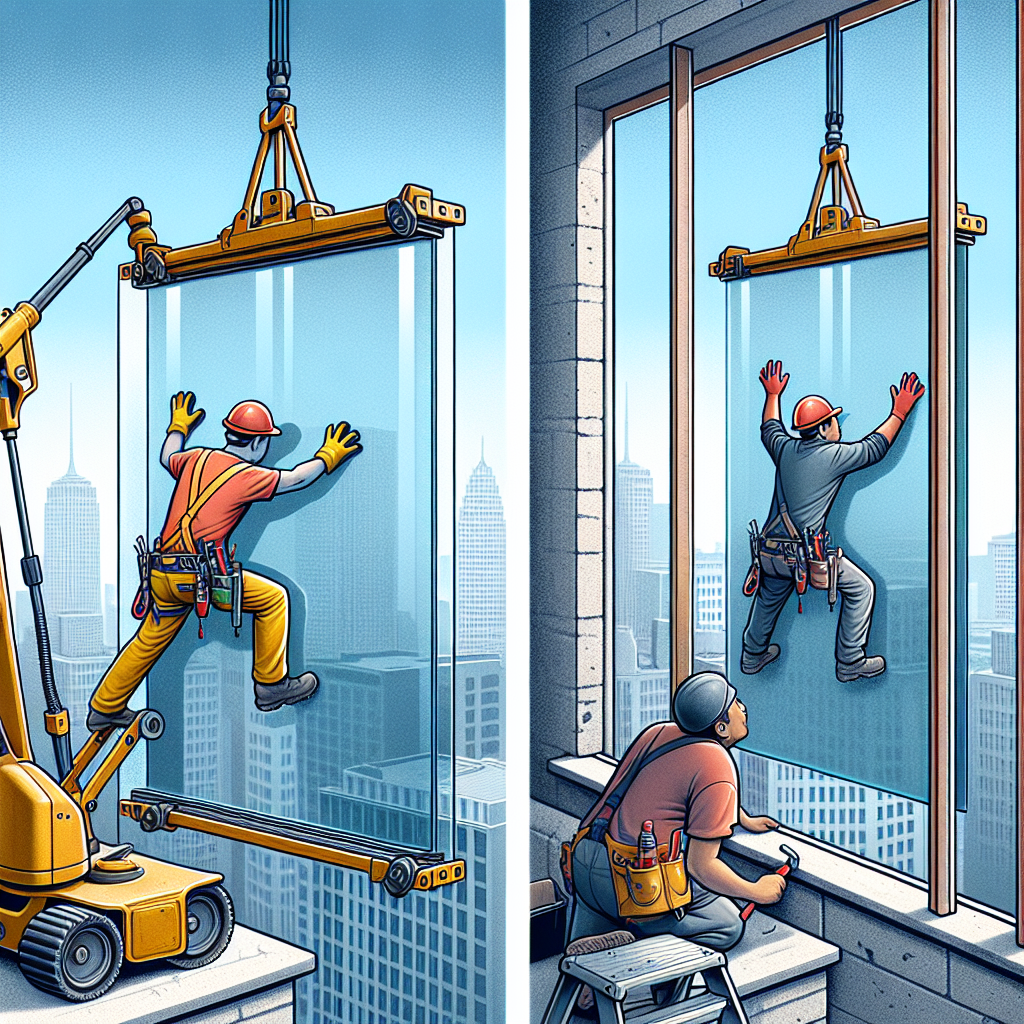

One of the main advantages of using a vacuum glass lifter is the speed at which glass panels can be installed. Traditionally, glass panels were manually lifted and positioned by a team of workers, which was a time-consuming and labor-intensive process. With a vacuum glass lifter, however, a single operator can easily lift and maneuver glass panels, significantly reducing the time and effort required for installation. This increased speed allows construction projects to be completed more quickly, saving both time and money.

In addition to speed, a vacuum glass lifter also improves safety on construction sites. Glass panels are heavy and fragile, making them prone to accidents and breakages during installation. By using a vacuum glass lifter, the risk of injury to workers and damage to the glass panels is greatly reduced. The lifter’s suction cups securely hold the glass in place, preventing it from slipping or falling. This not only protects the workers but also ensures that the glass panels are installed correctly, minimizing the need for costly repairs or replacements.

Furthermore, a vacuum glass lifter offers greater precision and control during installation. The lifter’s adjustable suction cups allow for precise positioning of the glass panels, ensuring a perfect fit every time. This level of accuracy is crucial in construction projects, especially when dealing with large and complex glass structures. The ability to precisely place glass panels not only improves the overall aesthetic of the building but also enhances its energy efficiency by minimizing air leakage.

Another advantage of using a vacuum glass lifter is its versatility. These lifters are designed to handle a wide range of glass sizes and shapes, making them suitable for various construction projects. Whether it’s installing small windows or large curtain walls, a vacuum glass lifter can easily adapt to different glass dimensions. This versatility eliminates the need for multiple lifting devices, saving both space and money on construction sites.

Lastly, a vacuum glass lifter is a cost-effective solution for construction companies. While the initial investment may seem high, the long-term benefits outweigh the costs. The increased efficiency and productivity provided by the lifter result in faster project completion, reducing labor costs. Additionally, the improved safety and precision minimize the risk of accidents and damages, saving money on repairs and replacements. Overall, the use of a vacuum glass lifter leads to significant cost savings for construction companies.

In conclusion, the advantages of using a vacuum glass lifter in construction are numerous. From increased efficiency and productivity to improved safety and precision, this innovative tool has transformed the way glass panels are handled and installed. Its speed, versatility, and cost-effectiveness make it an invaluable asset in the construction industry. As technology continues to advance, it is likely that vacuum glass lifters will become even more prevalent, further revolutionizing the construction process.

Enhanced Safety Measures and Risk Reduction with Vacuum Glass Lifters in Construction

The construction industry is known for its demanding and often hazardous working conditions. Workers are constantly exposed to risks and dangers that can lead to serious injuries or even fatalities. Therefore, it is crucial for construction companies to prioritize safety measures and risk reduction strategies to protect their workers. One such measure that has gained popularity in recent years is the use of vacuum glass lifters.

Vacuum glass lifters are specialized tools designed to lift and transport glass panels, windows, and other similar materials. They work by creating a vacuum seal between the lifter and the glass surface, allowing for a secure grip and safe handling. These lifters are typically operated by a single worker and can be attached to cranes, forklifts, or other lifting equipment.

One of the main advantages of using a vacuum glass lifter in construction is the enhanced safety it provides. Traditional methods of lifting and moving glass panels often involve manual labor and the use of ropes, slings, or clamps. These methods can be risky and prone to accidents, as they rely heavily on the strength and coordination of the workers involved. In contrast, vacuum glass lifters eliminate the need for manual lifting, reducing the risk of strain or overexertion injuries.

Furthermore, vacuum glass lifters offer a more secure and stable grip on the glass panels. The vacuum seal created by the lifter ensures that the glass remains firmly attached during the lifting and transportation process. This significantly reduces the chances of the glass slipping or falling, which can cause severe injuries to workers or damage to property. The stability provided by vacuum glass lifters also allows for more precise positioning of the glass panels, making installation or assembly tasks easier and more efficient.

Another advantage of using vacuum glass lifters is the time and cost savings they offer. Traditional methods of glass handling often require multiple workers and extensive preparation time. Workers need to carefully secure the glass panels using ropes or clamps, which can be time-consuming and labor-intensive. In contrast, vacuum glass lifters can be operated by a single worker, reducing the need for additional manpower. The quick and efficient operation of vacuum glass lifters also allows for faster project completion, saving construction companies valuable time and resources.

In addition to the enhanced safety and time savings, vacuum glass lifters also contribute to a cleaner and more environmentally friendly construction site. Traditional methods of glass handling often involve the use of excessive packaging materials, such as bubble wrap or cardboard, to protect the glass panels during transportation. These materials can generate a significant amount of waste and contribute to environmental pollution. Vacuum glass lifters eliminate the need for excessive packaging, as the secure grip provided by the lifter ensures that the glass panels remain intact and protected.

In conclusion, the use of vacuum glass lifters in construction offers numerous advantages, particularly in terms of enhanced safety measures and risk reduction. These lifters provide a secure and stable grip on glass panels, reducing the risk of accidents and injuries. They also offer time and cost savings, as well as contribute to a cleaner and more environmentally friendly construction site. By investing in vacuum glass lifters, construction companies can prioritize the safety and well-being of their workers while improving overall efficiency and productivity.

Cost Savings and Time Optimization through the Use of Vacuum Glass Lifters in Construction

The construction industry is constantly evolving, with new technologies and tools being developed to improve efficiency and safety on job sites. One such tool that has gained popularity in recent years is the vacuum glass lifter. This innovative device offers numerous advantages over traditional methods of lifting and installing glass panels, making it a valuable asset for construction projects.

One of the primary advantages of using a vacuum glass lifter is the cost savings it provides. In traditional glass installation methods, multiple workers are required to manually lift and position glass panels, which can be time-consuming and labor-intensive. With a vacuum glass lifter, however, a single operator can easily lift and maneuver glass panels, reducing the need for additional manpower. This not only saves on labor costs but also allows for more efficient use of resources, as workers can be allocated to other tasks on the job site.

In addition to cost savings, the use of a vacuum glass lifter also optimizes time on construction projects. The speed and precision with which glass panels can be lifted and installed using this tool significantly reduces the overall installation time. Traditional methods often involve the use of scaffolding or cranes, which can be time-consuming to set up and dismantle. With a vacuum glass lifter, the process is streamlined, as the device can be easily attached to the glass panel and lifted into place with minimal effort. This not only speeds up the installation process but also allows for quicker completion of other tasks that are dependent on the installation of glass panels.

Furthermore, the use of a vacuum glass lifter enhances safety on construction sites. Lifting and installing glass panels manually can be hazardous, as it requires workers to handle heavy and fragile materials. Accidents and injuries are not uncommon in such situations. However, with a vacuum glass lifter, the risk of accidents is significantly reduced. The device securely attaches to the glass panel, providing a stable and controlled lifting mechanism. This eliminates the need for workers to physically handle the glass, minimizing the risk of breakage or injury. Additionally, the vacuum glass lifter is equipped with safety features such as alarms and indicators, ensuring that operators are aware of any potential issues or malfunctions.

Another advantage of using a vacuum glass lifter is its versatility. These devices are designed to handle a wide range of glass panel sizes and shapes, making them suitable for various construction projects. Whether it’s installing large floor-to-ceiling windows or delicate glass partitions, a vacuum glass lifter can accommodate different requirements. This versatility eliminates the need for multiple tools or equipment, simplifying the logistics of glass installation and reducing costs associated with equipment rental or purchase.

In conclusion, the use of a vacuum glass lifter in construction offers numerous advantages. From cost savings and time optimization to enhanced safety and versatility, this innovative tool has revolutionized the way glass panels are lifted and installed. As the construction industry continues to evolve, it is crucial for contractors and project managers to embrace new technologies that can improve efficiency and productivity. The vacuum glass lifter is undoubtedly one such technology that has proven its worth in the construction industry.