Increased Efficiency and Productivity with Glass Lifter Suckers

The use of glass lifter suckers has become increasingly popular in the construction and manufacturing industries. These devices are designed to lift and transport large panes of glass with ease and efficiency. In this article, we will explore the advantages of using a glass lifter sucker for large panes, focusing on the increased efficiency and productivity that these devices offer.

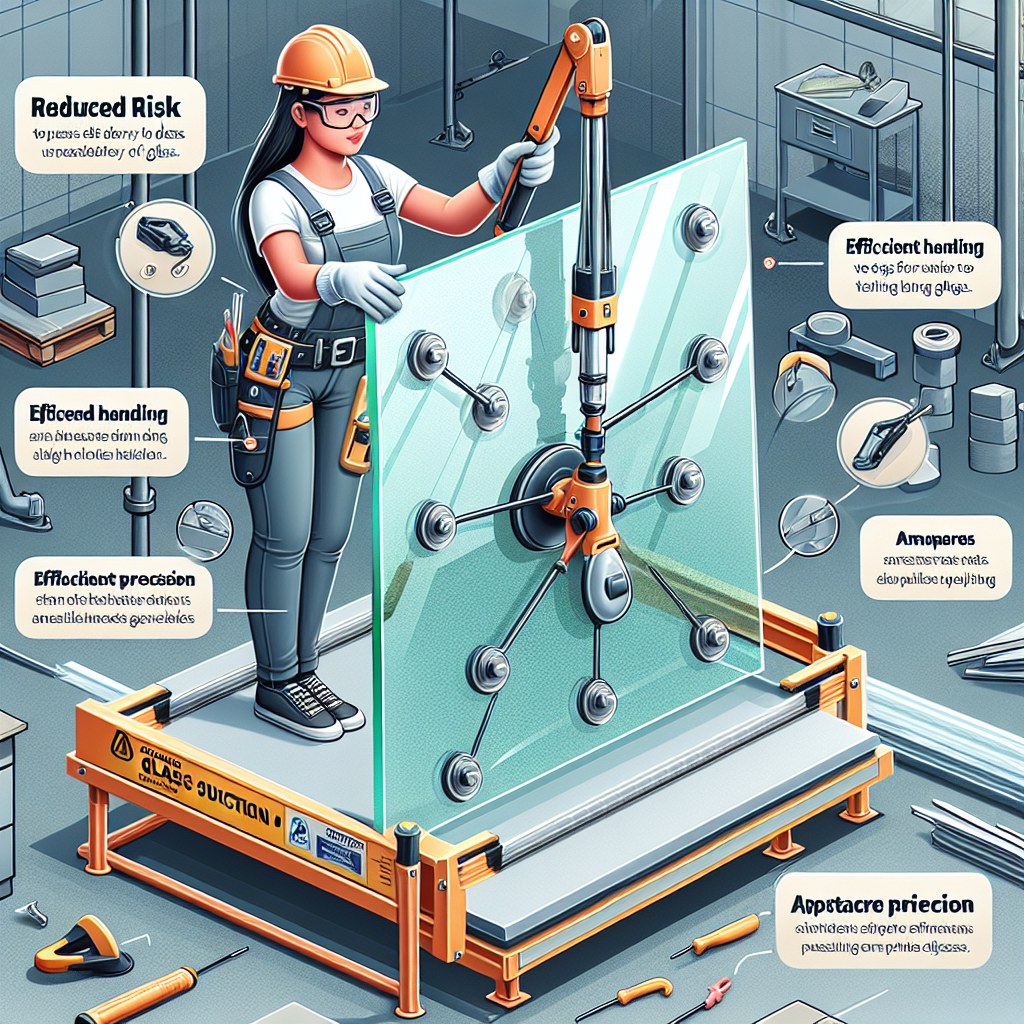

One of the main advantages of using a glass lifter sucker is the increased efficiency it provides. Traditional methods of lifting and moving large panes of glass often require multiple workers and can be time-consuming. With a glass lifter sucker, however, one person can easily handle the task. The device is equipped with powerful suction cups that securely grip the glass, allowing it to be lifted and moved effortlessly. This not only saves time but also reduces the risk of accidents and injuries that can occur when lifting heavy objects.

Another advantage of using a glass lifter sucker is the increased productivity it offers. By streamlining the process of lifting and moving large panes of glass, these devices enable workers to complete tasks more quickly and efficiently. This means that more work can be done in a shorter amount of time, resulting in increased productivity for the company. Additionally, the ease of use of glass lifter suckers allows workers to focus on other aspects of their job, rather than spending excessive time and energy on lifting and moving heavy objects.

Glass lifter suckers also offer a level of versatility that is not found with traditional lifting methods. These devices are designed to handle a wide range of glass sizes and shapes, making them suitable for various applications. Whether it is a large window pane or a delicate glass panel, a glass lifter sucker can securely grip and transport it without causing any damage. This versatility allows for greater flexibility in the workplace, as workers can easily adapt to different projects and requirements.

Furthermore, glass lifter suckers are designed with safety in mind. The suction cups are made from high-quality materials that provide a strong and secure grip on the glass. This ensures that the glass remains stable and does not slip or fall during transportation. Additionally, many glass lifter suckers are equipped with safety features such as alarms or indicators that alert the user if the suction is compromised. These safety measures help to prevent accidents and injuries, creating a safer working environment for employees.

In conclusion, the use of a glass lifter sucker for large panes offers numerous advantages, particularly in terms of increased efficiency and productivity. These devices streamline the process of lifting and moving heavy glass, allowing one person to handle the task with ease. The versatility of glass lifter suckers enables them to be used for various applications, while their safety features ensure a secure grip and prevent accidents. Overall, incorporating a glass lifter sucker into the workplace can greatly improve efficiency and productivity, making it a valuable investment for any company in the construction or manufacturing industry.

Enhanced Safety Measures Provided by Glass Lifter Suckers

The use of glass lifter suckers for handling large panes of glass offers several advantages, particularly when it comes to enhanced safety measures. These devices, also known as vacuum lifters or glass suction cups, are specifically designed to provide a secure grip on glass surfaces, allowing for easy lifting and maneuvering. By utilizing the power of suction, glass lifter suckers eliminate the need for manual handling, reducing the risk of accidents and injuries.

One of the primary safety benefits of using a glass lifter sucker is the elimination of physical strain on workers. Lifting and carrying heavy glass panes manually can put a significant amount of stress on the body, particularly the back and shoulders. This can lead to muscle strains, sprains, and even more serious injuries. With a glass lifter sucker, the weight of the glass is evenly distributed across the device, reducing the strain on individual muscles and joints. This not only minimizes the risk of immediate injuries but also helps prevent long-term musculoskeletal issues.

In addition to reducing physical strain, glass lifter suckers also provide a secure grip on the glass, preventing accidental drops and breakages. The suction cups are designed to create a strong vacuum seal with the glass surface, ensuring a reliable hold. This is especially important when dealing with large and heavy panes of glass, which can be difficult to handle safely without the aid of a lifting device. By securely gripping the glass, the lifter sucker allows for controlled and precise movements, minimizing the risk of accidents and damage.

Furthermore, glass lifter suckers often come equipped with additional safety features to further enhance their functionality. Many models include built-in safety alarms or indicators that alert the operator if the vacuum seal is compromised. This ensures that any potential risks are immediately identified, allowing for prompt action to be taken. Some devices also have a backup power source or a manual release valve, providing a fail-safe mechanism in case of power failure or other emergencies. These safety features provide peace of mind to both the operators and those in the vicinity of the glass being lifted.

Another advantage of using a glass lifter sucker is the increased efficiency and productivity it offers. With manual handling, it can be time-consuming and labor-intensive to lift and position large glass panes accurately. The use of a lifter sucker streamlines the process, allowing for quicker and more precise movements. This not only saves time but also reduces the risk of errors or damage caused by human error. By improving efficiency, glass lifter suckers contribute to a smoother workflow and increased productivity.

In conclusion, the use of glass lifter suckers for handling large panes of glass provides several advantages, particularly in terms of enhanced safety measures. These devices eliminate physical strain on workers, provide a secure grip on the glass, and often come equipped with additional safety features. Furthermore, they improve efficiency and productivity by streamlining the lifting and positioning process. By utilizing a glass lifter sucker, businesses can ensure the safety of their workers, protect valuable glass materials, and optimize their operations.

Cost Savings and Time Benefits of Using Glass Lifter Suckers

The Advantages of Using a Glass Lifter Sucker for Large Panes

When it comes to handling large panes of glass, efficiency and safety are of utmost importance. Traditional methods of lifting and moving these heavy and fragile objects often involve multiple workers and specialized equipment. However, there is a more cost-effective and time-saving solution available – the glass lifter sucker.

One of the primary advantages of using a glass lifter sucker is the significant cost savings it offers. In the past, moving large panes of glass required the use of cranes or forklifts, which can be expensive to rent or purchase. Additionally, these machines often require trained operators, adding to the overall labor costs. With a glass lifter sucker, only one worker is needed to operate the device, eliminating the need for additional manpower. This not only reduces labor expenses but also frees up other workers to focus on different tasks, increasing overall productivity.

Furthermore, the glass lifter sucker eliminates the need for additional equipment such as slings or straps. These accessories can be costly to purchase and maintain, and they often require regular inspections to ensure their safety. By using a glass lifter sucker, there is no need for these extra expenses, resulting in significant cost savings for businesses.

In addition to cost savings, using a glass lifter sucker also offers time benefits. Traditional methods of moving large panes of glass can be time-consuming and labor-intensive. Workers often need to carefully maneuver the glass into position, taking extra precautions to avoid damage. This process can be slow and tedious, especially when dealing with delicate or irregularly shaped panes.

With a glass lifter sucker, the process becomes much quicker and more efficient. The device uses suction cups to securely grip the glass, allowing it to be lifted and moved with ease. This eliminates the need for manual handling, reducing the risk of accidents and injuries. Moreover, the glass lifter sucker is designed to provide a stable and controlled grip, ensuring that the glass remains in place during transportation. This saves valuable time that would otherwise be spent on readjusting or repositioning the glass.

Another time-saving advantage of using a glass lifter sucker is its versatility. These devices are designed to handle a wide range of glass sizes and shapes, making them suitable for various applications. Whether it’s a large window pane or a delicate glass panel, the glass lifter sucker can securely lift and transport it without any hassle. This eliminates the need for specialized equipment for different types of glass, streamlining the process and saving time.

In conclusion, the advantages of using a glass lifter sucker for large panes are clear. Not only does it offer significant cost savings by reducing labor and equipment expenses, but it also provides time benefits through its efficient and versatile design. By investing in a glass lifter sucker, businesses can improve their productivity, enhance worker safety, and ultimately achieve greater success in handling large panes of glass.