Increased Safety and Risk Mitigation in High-Risk Environments

The Advantages of Pneumatic Glass Lifters in High-Risk Environments

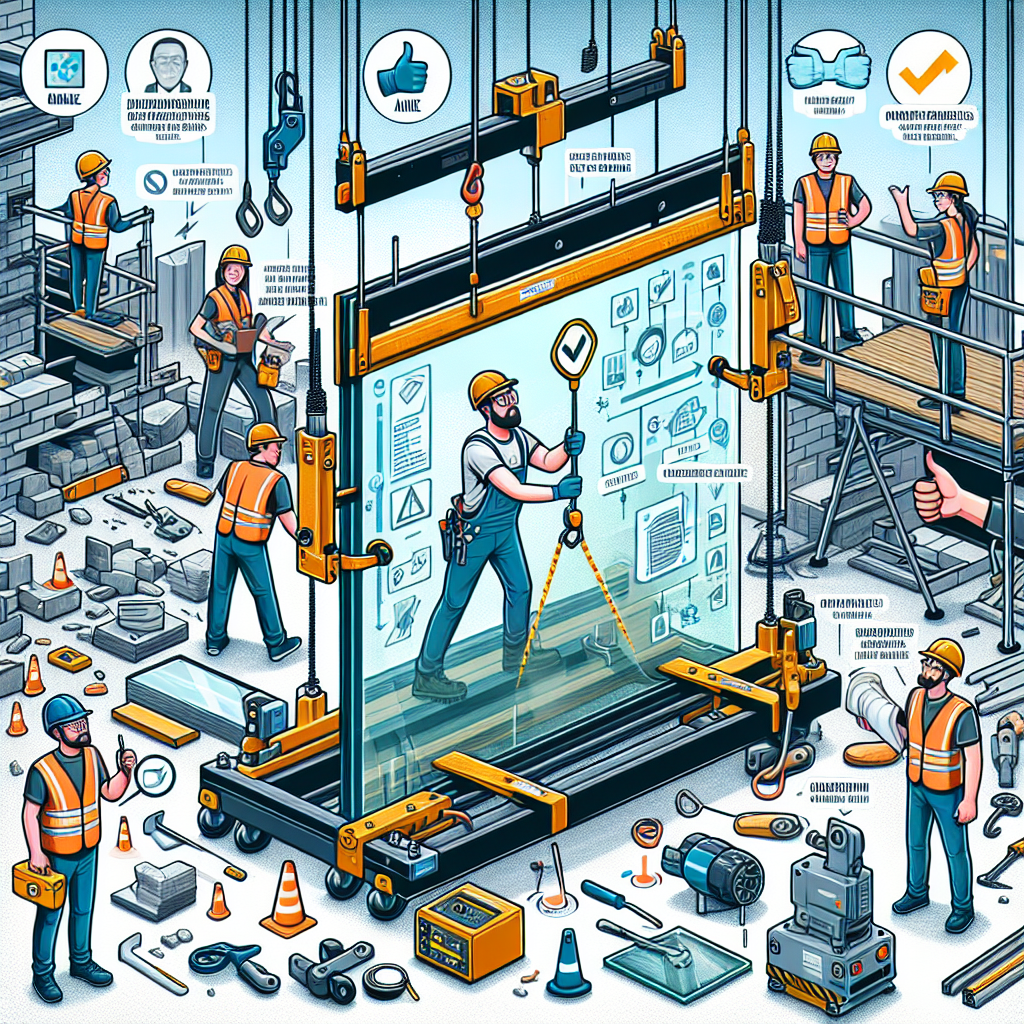

In high-risk environments, safety is of utmost importance. Whether it’s a construction site, a manufacturing facility, or any other hazardous location, the well-being of workers and the prevention of accidents are top priorities. One area where safety measures are crucial is in the handling of heavy and fragile materials, such as glass. This is where pneumatic glass lifters come into play, offering a range of advantages that contribute to increased safety and risk mitigation.

One of the primary advantages of pneumatic glass lifters is their ability to reduce the risk of accidents and injuries. Traditional methods of lifting and moving glass involve manual labor, which can be physically demanding and prone to human error. With pneumatic glass lifters, the need for manual lifting is eliminated, reducing the risk of strain, muscle fatigue, and back injuries. This not only protects the well-being of workers but also minimizes the chances of accidents caused by human error.

Furthermore, pneumatic glass lifters provide a secure and stable grip on glass panels, ensuring that they are held firmly in place during transportation. This is particularly important in high-risk environments where sudden movements or vibrations can occur. The use of pneumatic technology allows for a controlled and steady lifting process, minimizing the risk of glass panels slipping or falling. This not only protects workers from potential injuries but also prevents damage to the glass itself, reducing the need for costly replacements.

Another advantage of pneumatic glass lifters is their versatility. These lifters can be easily adjusted to accommodate different sizes and shapes of glass panels, making them suitable for a wide range of applications. Whether it’s lifting large sheets of glass or maneuvering smaller, more delicate pieces, pneumatic glass lifters can be customized to meet specific requirements. This flexibility not only enhances efficiency but also reduces the risk of accidents caused by improper handling or inadequate equipment.

In addition to their safety benefits, pneumatic glass lifters also contribute to increased productivity in high-risk environments. The use of these lifters eliminates the need for manual labor, allowing workers to focus on other tasks that require their expertise. This not only saves time but also improves overall efficiency. Furthermore, the secure grip provided by pneumatic glass lifters allows for faster and more precise transportation of glass panels, reducing the risk of delays or damage during the process.

Lastly, pneumatic glass lifters offer a cost-effective solution for high-risk environments. While the initial investment may be higher compared to traditional lifting methods, the long-term benefits outweigh the costs. The reduction in accidents and injuries leads to lower healthcare and insurance expenses. Additionally, the prevention of glass damage minimizes the need for costly replacements. Overall, the use of pneumatic glass lifters proves to be a wise investment that not only ensures safety but also saves money in the long run.

In conclusion, the advantages of pneumatic glass lifters in high-risk environments are undeniable. From increased safety and risk mitigation to improved productivity and cost-effectiveness, these lifters offer a range of benefits that contribute to a safer and more efficient working environment. By eliminating manual lifting, providing a secure grip, and offering versatility, pneumatic glass lifters prove to be an invaluable tool in the handling of glass panels. In high-risk environments, where safety is paramount, investing in pneumatic glass lifters is a decision that pays off in more ways than one.

Enhanced Efficiency and Productivity with Pneumatic Glass Lifters

The use of pneumatic glass lifters in high-risk environments offers numerous advantages, particularly when it comes to enhancing efficiency and productivity. These innovative devices are specifically designed to handle heavy glass panels, making them an ideal solution for industries such as construction, manufacturing, and transportation. By utilizing the power of compressed air, pneumatic glass lifters provide a safe and efficient way to lift, move, and position glass panels, reducing the risk of accidents and injuries.

One of the key advantages of pneumatic glass lifters is their ability to handle heavy loads with ease. These lifters are equipped with powerful suction cups that create a vacuum seal on the glass surface, allowing them to securely grip and lift even the heaviest panels. This eliminates the need for manual lifting, which can be physically demanding and time-consuming. With pneumatic glass lifters, workers can effortlessly move large glass panels, saving both time and energy.

In addition to their lifting capabilities, pneumatic glass lifters also offer enhanced maneuverability. These devices are typically equipped with swivel mechanisms that allow for 360-degree rotation, making it easy to position glass panels precisely. This level of control is particularly beneficial in high-risk environments where accuracy is crucial. By using pneumatic glass lifters, workers can ensure that glass panels are placed exactly where they need to be, reducing the risk of errors and rework.

Furthermore, pneumatic glass lifters contribute to a safer working environment. In high-risk industries, such as construction, accidents involving glass panels can have severe consequences. Pneumatic glass lifters minimize the risk of accidents by securely gripping the glass and preventing it from slipping or falling. The vacuum seal created by the suction cups ensures that the glass remains firmly in place throughout the lifting and moving process. This not only protects workers from potential injuries but also prevents damage to the glass panels, reducing the risk of costly replacements.

Another advantage of pneumatic glass lifters is their versatility. These devices can be easily attached to various lifting equipment, such as cranes or forklifts, allowing for seamless integration into existing workflows. This versatility enables businesses to maximize their investment in pneumatic glass lifters by using them in different applications and environments. Whether it’s lifting glass panels onto a building facade or loading them onto a transportation vehicle, pneumatic glass lifters can adapt to different scenarios, enhancing overall efficiency and productivity.

In conclusion, the use of pneumatic glass lifters in high-risk environments offers significant advantages in terms of efficiency and productivity. These devices provide a safe and efficient way to handle heavy glass panels, reducing the risk of accidents and injuries. With their lifting capabilities, maneuverability, and versatility, pneumatic glass lifters contribute to a more efficient workflow, allowing workers to move glass panels with ease and precision. By investing in pneumatic glass lifters, businesses can enhance their operations, improve safety, and ultimately increase productivity in high-risk environments.

Cost Savings and Long-Term Benefits of Pneumatic Glass Lifters

Pneumatic glass lifters have become increasingly popular in high-risk environments due to their numerous advantages. One of the key benefits of using these lifters is the cost savings they offer, along with the long-term benefits they provide.

First and foremost, pneumatic glass lifters are cost-effective. Traditional methods of lifting and moving glass involve manual labor, which can be time-consuming and expensive. By using pneumatic glass lifters, companies can significantly reduce labor costs. These lifters are designed to handle heavy loads with ease, allowing for efficient and quick glass installation. This means that fewer workers are needed to complete the job, resulting in reduced labor expenses.

Moreover, pneumatic glass lifters are highly versatile, making them a valuable investment for companies operating in high-risk environments. These lifters can be easily adjusted to accommodate different sizes and shapes of glass, eliminating the need for multiple lifting devices. This versatility not only saves money but also reduces the risk of accidents and injuries that can occur when using inappropriate lifting equipment.

In addition to cost savings, pneumatic glass lifters offer long-term benefits. One such benefit is increased productivity. With traditional methods, the process of lifting and installing glass can be slow and cumbersome. Pneumatic glass lifters, on the other hand, streamline the process, allowing for faster and more efficient installation. This increased productivity translates into shorter project timelines and improved overall efficiency.

Furthermore, pneumatic glass lifters are designed with safety in mind. High-risk environments often involve working at heights or in confined spaces, which can be dangerous. Pneumatic glass lifters are equipped with safety features such as non-slip grips and secure locking mechanisms, ensuring that the glass remains stable during lifting and installation. This reduces the risk of accidents and injuries, protecting both workers and the glass itself.

Another long-term benefit of pneumatic glass lifters is their durability. These lifters are built to withstand the demands of high-risk environments, such as extreme temperatures and harsh weather conditions. Unlike traditional lifting methods that may wear out over time, pneumatic glass lifters are designed to last, providing companies with a reliable and long-lasting solution.

Additionally, pneumatic glass lifters require minimal maintenance. Traditional lifting equipment often requires regular servicing and repairs, which can be costly and time-consuming. Pneumatic glass lifters, on the other hand, are low-maintenance devices that require minimal upkeep. This not only saves money but also ensures that the lifters are always in optimal working condition, ready to be used whenever needed.

In conclusion, the advantages of pneumatic glass lifters in high-risk environments are numerous. From cost savings to long-term benefits, these lifters offer a valuable solution for companies operating in challenging conditions. By reducing labor costs, increasing productivity, and prioritizing safety, pneumatic glass lifters prove to be a wise investment for any company looking to streamline their glass installation processes. With their durability and low-maintenance requirements, these lifters provide a reliable and efficient solution that can withstand the demands of high-risk environments.