Benefits of Using Pneumatic Glass Lifters for Heavy Lifting Tasks

Pneumatic Glass Lifters: What You Need to Know Before Buying

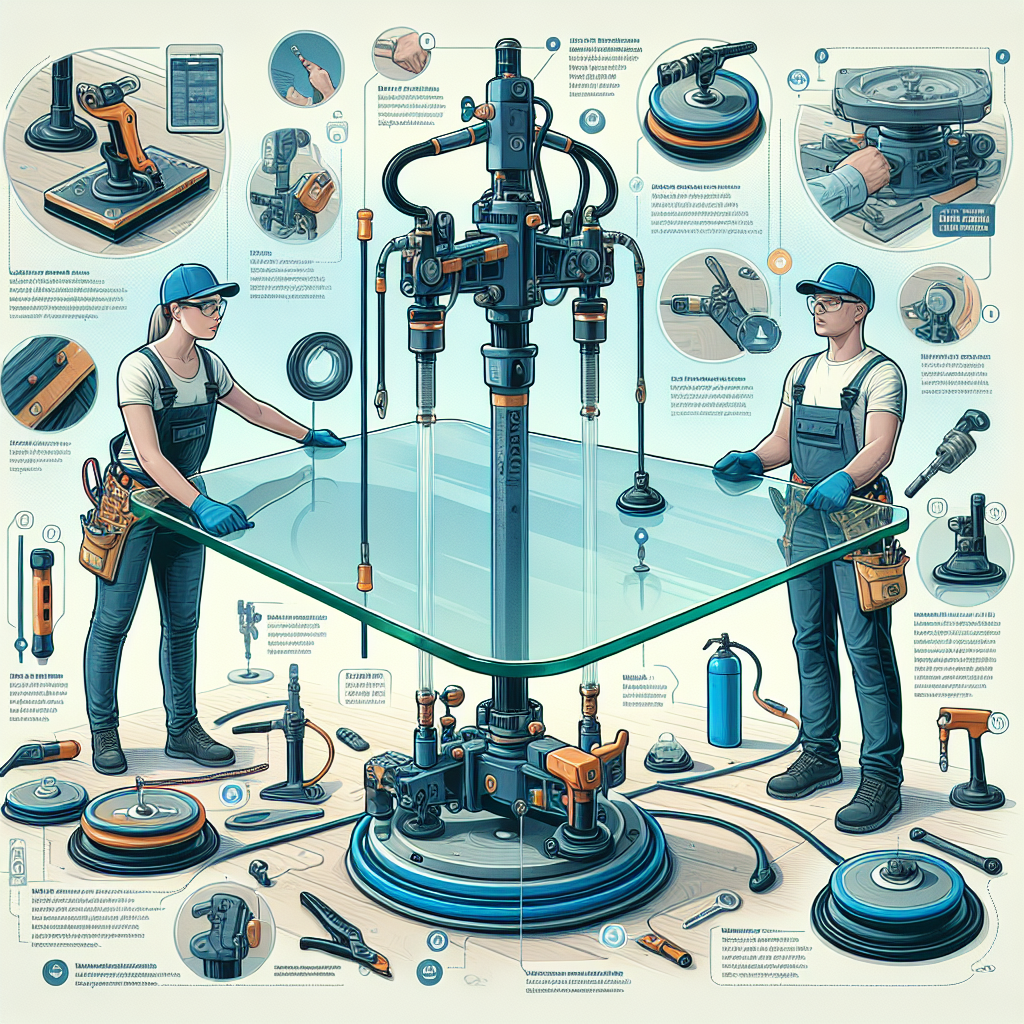

When it comes to heavy lifting tasks, having the right equipment is crucial. One such equipment that has gained popularity in recent years is the pneumatic glass lifter. These devices are specifically designed to handle the delicate and often challenging task of lifting and moving glass panels. In this article, we will explore the benefits of using pneumatic glass lifters for heavy lifting tasks.

One of the primary advantages of pneumatic glass lifters is their ability to provide a secure and stable grip on glass panels. Unlike traditional lifting methods that rely on manual labor or suction cups, pneumatic glass lifters use a combination of vacuum and compressed air to create a strong hold on the glass surface. This ensures that the glass remains firmly in place during the lifting process, reducing the risk of accidents or damage.

Another benefit of pneumatic glass lifters is their versatility. These devices are designed to handle a wide range of glass sizes and shapes, making them suitable for various applications. Whether you need to lift small glass panels or large, heavy sheets, pneumatic glass lifters can accommodate your needs. This versatility makes them an excellent choice for industries such as construction, manufacturing, and glazing.

In addition to their versatility, pneumatic glass lifters also offer increased efficiency and productivity. With traditional lifting methods, it often takes multiple workers to lift and move heavy glass panels. This not only increases labor costs but also slows down the overall workflow. Pneumatic glass lifters, on the other hand, can be operated by a single person, reducing the need for additional manpower. This allows for faster and more efficient completion of tasks, ultimately saving time and money.

Furthermore, pneumatic glass lifters are designed with safety in mind. These devices are equipped with various safety features, such as audible alarms and visual indicators, to alert operators of any potential issues. Additionally, the vacuum and compressed air system used by pneumatic glass lifters ensures a secure grip on the glass, minimizing the risk of accidents or injuries. By investing in a pneumatic glass lifter, you can create a safer working environment for your employees and reduce the likelihood of costly accidents.

Lastly, pneumatic glass lifters are relatively easy to operate and maintain. Most models come with user-friendly controls and intuitive interfaces, allowing operators to quickly learn how to use them. Additionally, routine maintenance tasks, such as cleaning and inspecting the lifter, are straightforward and can be easily performed by your maintenance staff. This means that you can integrate pneumatic glass lifters into your operations without significant disruptions or additional training requirements.

In conclusion, pneumatic glass lifters offer numerous benefits for heavy lifting tasks involving glass panels. From their secure grip and versatility to increased efficiency and safety features, these devices are a valuable investment for industries that frequently handle glass. By understanding the advantages of pneumatic glass lifters, you can make an informed decision when it comes to purchasing the right equipment for your lifting needs.

Key Features to Consider When Choosing a Pneumatic Glass Lifter

Pneumatic glass lifters are essential tools for any construction or manufacturing project that involves handling large glass panels. These lifters use compressed air to create a vacuum seal, allowing them to securely grip and lift heavy glass with ease. If you are in the market for a pneumatic glass lifter, there are several key features you should consider before making your purchase.

First and foremost, you need to consider the lifting capacity of the glass lifter. This refers to the maximum weight that the lifter can safely handle. It is crucial to choose a lifter with a lifting capacity that matches the weight of the glass panels you will be working with. Overloading a glass lifter can lead to accidents and damage to the glass, so it is essential to choose a lifter that can handle the weight you require.

Another important feature to consider is the size and shape of the suction cups. The suction cups are the part of the lifter that comes into direct contact with the glass. They need to be large enough to provide a secure grip on the glass surface. Additionally, the shape of the suction cups should be compatible with the shape of the glass panels you will be working with. Some lifters come with interchangeable suction cups, allowing you to adapt the lifter to different glass shapes and sizes.

The type of control system is another crucial factor to consider. Some glass lifters come with manual controls, while others have remote control systems. Manual control systems require the operator to be in close proximity to the lifter, which may not be ideal for certain situations. Remote control systems, on the other hand, allow the operator to control the lifter from a distance, providing greater flexibility and safety.

Safety features are of utmost importance when it comes to working with heavy glass panels. Look for a glass lifter that has safety mechanisms such as audible alarms and visual indicators to alert the operator of any potential issues. Additionally, some lifters come with automatic shut-off systems that activate when the lifter loses vacuum pressure, preventing accidents and damage to the glass.

Portability is another factor to consider, especially if you will be using the glass lifter in different locations. Look for a lifter that is lightweight and easy to transport. Some lifters come with built-in wheels or handles, making them easier to move around. Additionally, consider the power source of the lifter. Some models are battery-powered, while others require an external power source. Choose a lifter that suits your specific needs and preferences.

Lastly, consider the overall build quality and durability of the glass lifter. Look for a lifter that is made from high-quality materials and has a sturdy construction. This will ensure that the lifter can withstand the rigors of daily use and last for a long time.

In conclusion, when choosing a pneumatic glass lifter, it is essential to consider key features such as lifting capacity, suction cup size and shape, control system, safety features, portability, and build quality. By carefully evaluating these features, you can select a glass lifter that meets your specific requirements and ensures safe and efficient handling of glass panels in your projects.

Safety Precautions and Maintenance Tips for Pneumatic Glass Lifters

Pneumatic glass lifters are a valuable tool for handling and transporting glass panels. They use compressed air to create a vacuum, allowing them to securely grip and lift glass without the need for manual handling. While these lifters offer many benefits, it is important to understand the safety precautions and maintenance tips associated with their use.

Safety should always be the top priority when using pneumatic glass lifters. Before operating the lifter, it is crucial to ensure that all personnel involved are properly trained in its use. This includes understanding how to operate the lifter safely, as well as being aware of any potential hazards that may arise during the lifting process.

One important safety precaution is to always inspect the lifter before each use. This includes checking for any signs of damage or wear, such as cracks in the vacuum cups or leaks in the air hoses. Any damaged components should be replaced immediately to prevent accidents or equipment failure.

It is also essential to properly secure the glass panels to the lifter. This can be done by ensuring that the vacuum cups are clean and free from any debris that may affect their ability to create a strong vacuum seal. Additionally, it is important to position the lifter correctly on the glass panel, ensuring that the vacuum cups are evenly distributed and aligned with the panel’s center of gravity.

During the lifting process, it is crucial to maintain a clear and safe working area. This means removing any obstacles or debris that may interfere with the lifter’s movement or cause the glass panel to shift unexpectedly. It is also important to communicate effectively with other personnel involved in the lifting operation to ensure that everyone is aware of their roles and responsibilities.

Regular maintenance is essential to keep pneumatic glass lifters in optimal working condition. This includes cleaning the vacuum cups and air hoses regularly to prevent any blockages or obstructions that may affect the lifter’s performance. It is also important to inspect and replace any worn or damaged components, such as seals or gaskets, to ensure that the lifter maintains a strong vacuum seal.

In addition to regular maintenance, it is important to follow the manufacturer’s recommended service schedule. This may include periodic inspections and servicing by qualified technicians to ensure that the lifter is functioning properly and to identify any potential issues before they become major problems.

Proper storage of pneumatic glass lifters is also important to prevent damage and ensure their longevity. When not in use, the lifter should be stored in a clean and dry environment, away from any potential sources of damage or contamination. It is also important to store the lifter in a secure location to prevent unauthorized use or access.

In conclusion, pneumatic glass lifters are a valuable tool for handling and transporting glass panels. However, it is important to prioritize safety and follow proper maintenance procedures to ensure their safe and efficient operation. By following these safety precautions and maintenance tips, you can maximize the lifespan of your pneumatic glass lifter and minimize the risk of accidents or equipment failure.