The Importance of Pneumatic Glass Lifters in Preventing Accidents during Glass Installation

Pneumatic Glass Lifters: Enhancing Safety in Glass Installation

Glass installation can be a complex and hazardous task, requiring careful planning and execution to ensure the safety of workers and the integrity of the glass. Accidents during glass installation can result in serious injuries or even fatalities, making it crucial to prioritize safety measures. One effective tool that has revolutionized the industry is the pneumatic glass lifter, which plays a vital role in preventing accidents and enhancing safety during glass installation.

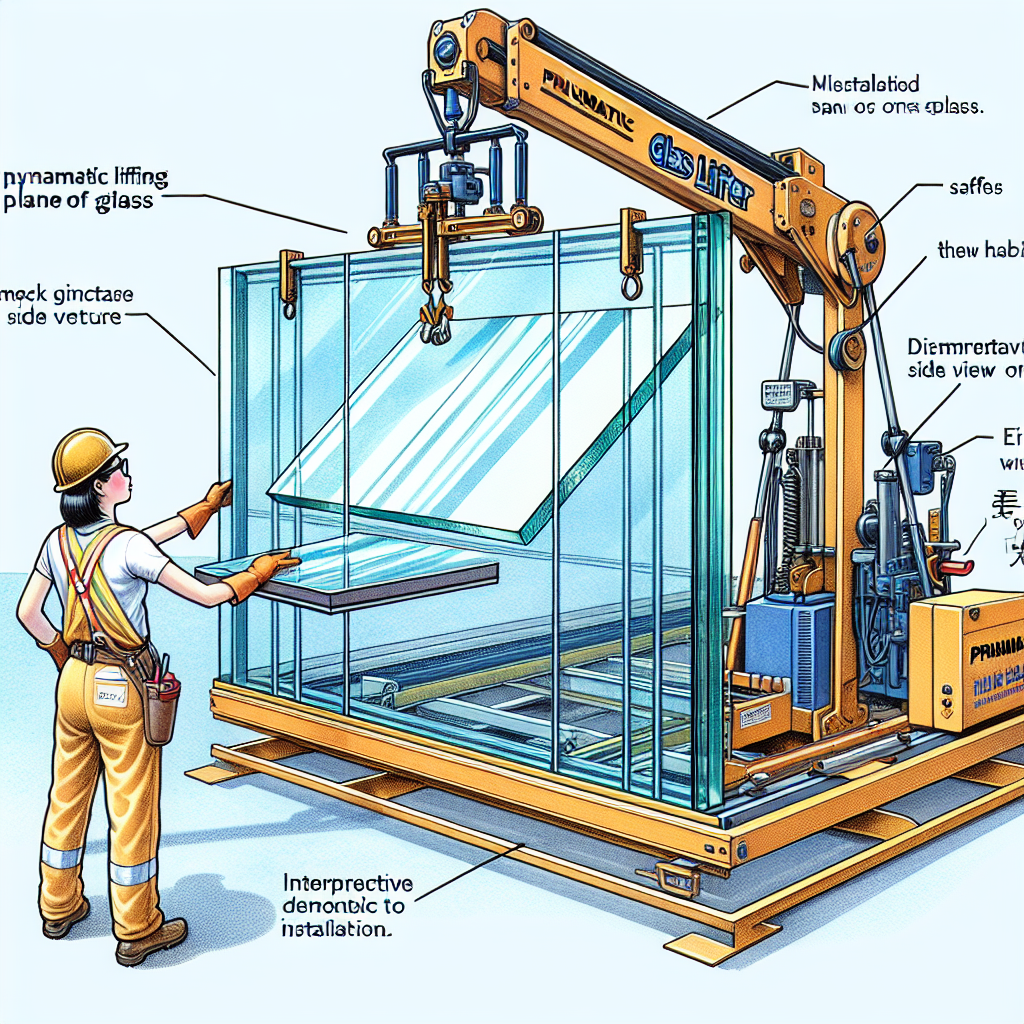

The importance of pneumatic glass lifters in preventing accidents cannot be overstated. These devices are specifically designed to lift and transport glass panels, reducing the risk of mishandling and breakage. By utilizing a vacuum system, pneumatic glass lifters securely grip the glass, providing a reliable and stable lifting mechanism. This eliminates the need for manual lifting, which can be physically demanding and prone to human error.

One of the key advantages of pneumatic glass lifters is their ability to handle heavy loads with ease. Glass panels can be extremely heavy and cumbersome, making them difficult to lift and maneuver. Pneumatic glass lifters are equipped with powerful suction cups that can support the weight of large glass panels, ensuring a secure grip throughout the lifting process. This not only reduces the risk of accidents caused by dropping or slipping glass but also minimizes the strain on workers’ bodies, preventing injuries such as back strains or muscle sprains.

Furthermore, pneumatic glass lifters offer enhanced control and precision during glass installation. These devices are equipped with adjustable suction cups, allowing for precise positioning of the glass panels. This level of control is essential when working in tight or confined spaces, where even the slightest misalignment can lead to accidents or damage to the glass. With pneumatic glass lifters, workers can easily adjust the position of the glass panels, ensuring a perfect fit and minimizing the risk of accidents or costly mistakes.

In addition to their safety benefits, pneumatic glass lifters also improve efficiency and productivity in glass installation projects. These devices are designed to streamline the lifting and transportation process, reducing the time and effort required to install glass panels. By eliminating the need for manual lifting and carrying, workers can focus on other critical tasks, such as sealing or securing the glass. This not only speeds up the installation process but also allows for a smoother workflow, minimizing downtime and maximizing productivity.

It is worth noting that pneumatic glass lifters are not only limited to large-scale commercial projects. They are also highly versatile and can be used in various applications, including residential glass installation or renovation projects. Whether it is installing windows, glass doors, or shower enclosures, pneumatic glass lifters provide a safe and efficient solution for handling glass panels of all sizes.

In conclusion, the importance of pneumatic glass lifters in preventing accidents during glass installation cannot be overstated. These devices enhance safety by securely gripping and lifting glass panels, reducing the risk of mishandling and breakage. They also offer enhanced control and precision, ensuring accurate positioning of the glass and minimizing the risk of accidents or damage. Furthermore, pneumatic glass lifters improve efficiency and productivity, streamlining the installation process and allowing workers to focus on other critical tasks. With their versatility and safety benefits, pneumatic glass lifters have become an indispensable tool in the glass installation industry, enhancing safety and ensuring the successful completion of projects.

How Pneumatic Glass Lifters Improve Efficiency and Productivity in Glass Installation Projects

Pneumatic glass lifters have revolutionized the glass installation industry, providing a safer and more efficient way to handle and install glass panels. These innovative devices utilize the power of compressed air to lift and transport heavy glass panels, reducing the risk of accidents and injuries that are commonly associated with manual lifting.

One of the key advantages of pneumatic glass lifters is their ability to improve efficiency and productivity in glass installation projects. Traditional methods of glass installation often require a team of workers to manually lift and position glass panels, which can be time-consuming and physically demanding. With pneumatic glass lifters, a single operator can easily handle and maneuver glass panels, significantly reducing the manpower required for the job.

The efficiency of pneumatic glass lifters is further enhanced by their quick and easy setup. These devices are designed to be portable and lightweight, allowing them to be easily transported to the worksite and set up in a matter of minutes. This eliminates the need for complex rigging and hoisting equipment, saving valuable time and resources.

In addition to improving efficiency, pneumatic glass lifters also enhance productivity in glass installation projects. These devices are equipped with powerful suction cups that securely grip glass panels, allowing for precise positioning and alignment. This eliminates the need for constant readjustment and ensures that glass panels are installed accurately the first time, reducing the risk of errors and rework.

Furthermore, pneumatic glass lifters are designed to handle a wide range of glass sizes and shapes, making them versatile tools for glass installation projects. Whether it’s large floor-to-ceiling windows or intricate glass partitions, these lifters can easily accommodate different types of glass panels, providing flexibility and adaptability to the installation process.

Another significant advantage of pneumatic glass lifters is their contribution to safety in glass installation. Manual lifting of heavy glass panels can pose serious risks to workers, including back injuries, strains, and falls. Pneumatic glass lifters eliminate these risks by taking the strain off workers’ bodies and providing a secure and stable lifting mechanism.

Moreover, these lifters are equipped with safety features such as audible alarms and visual indicators that alert operators to any potential issues or malfunctions. This ensures that operators are aware of any potential hazards and can take immediate action to prevent accidents.

In conclusion, pneumatic glass lifters have become an essential tool in the glass installation industry, offering numerous benefits in terms of efficiency, productivity, and safety. By reducing the physical strain on workers and providing precise and secure lifting capabilities, these devices have revolutionized the way glass panels are handled and installed. With their quick setup and versatility, pneumatic glass lifters have become a valuable asset for any glass installation project, enhancing both the speed and quality of the installation process.

Exploring the Versatility and Benefits of Pneumatic Glass Lifters in Various Glass Installation Applications

Pneumatic glass lifters have revolutionized the glass installation industry, providing a safe and efficient way to handle and install glass panels. These versatile machines have become an essential tool for glaziers and contractors, offering numerous benefits in a wide range of glass installation applications.

One of the key advantages of pneumatic glass lifters is their ability to handle heavy and fragile glass panels with ease. Traditional methods of glass installation often involved manual lifting, which posed significant safety risks for workers. Pneumatic glass lifters eliminate the need for manual lifting, reducing the risk of injuries and accidents. These machines use compressed air to create a vacuum seal, securely gripping the glass panel and allowing it to be lifted and maneuvered effortlessly.

In addition to enhancing safety, pneumatic glass lifters also improve efficiency and productivity in glass installation projects. With traditional methods, multiple workers were often required to lift and position glass panels, slowing down the installation process. Pneumatic glass lifters can be operated by a single person, significantly reducing labor costs and increasing productivity. These machines are also equipped with adjustable suction cups, allowing for precise positioning of glass panels, further streamlining the installation process.

The versatility of pneumatic glass lifters is another reason why they have become a popular choice in the glass installation industry. These machines can be used for a wide range of applications, including the installation of windows, doors, curtain walls, and glass partitions. Whether it’s a small residential project or a large commercial building, pneumatic glass lifters can handle the job with ease. They can lift glass panels of various sizes and shapes, making them suitable for any type of glass installation project.

Furthermore, pneumatic glass lifters are not limited to indoor applications. They can also be used for outdoor glass installation projects, such as the installation of glass facades on high-rise buildings. These machines are designed to withstand harsh weather conditions and can safely lift and position glass panels at great heights. This versatility makes pneumatic glass lifters a valuable tool for glaziers working on both indoor and outdoor projects.

Another benefit of pneumatic glass lifters is their ease of use. These machines are designed to be user-friendly, with intuitive controls and adjustable settings. Operators can easily adjust the suction cups to accommodate different glass panel sizes and weights. The machines are also equipped with safety features, such as audible alarms and visual indicators, to ensure that the glass panels are securely held in place during lifting and installation.

In conclusion, pneumatic glass lifters have revolutionized the glass installation industry by enhancing safety, improving efficiency, and offering versatility in various glass installation applications. These machines have become an essential tool for glaziers and contractors, providing a safe and efficient way to handle and install glass panels. With their ability to handle heavy and fragile glass panels, streamline the installation process, and accommodate different project requirements, pneumatic glass lifters have become a game-changer in the glass installation industry.