Increased Efficiency and Safety in Glass Handling with Pneumatic Glass Lifters

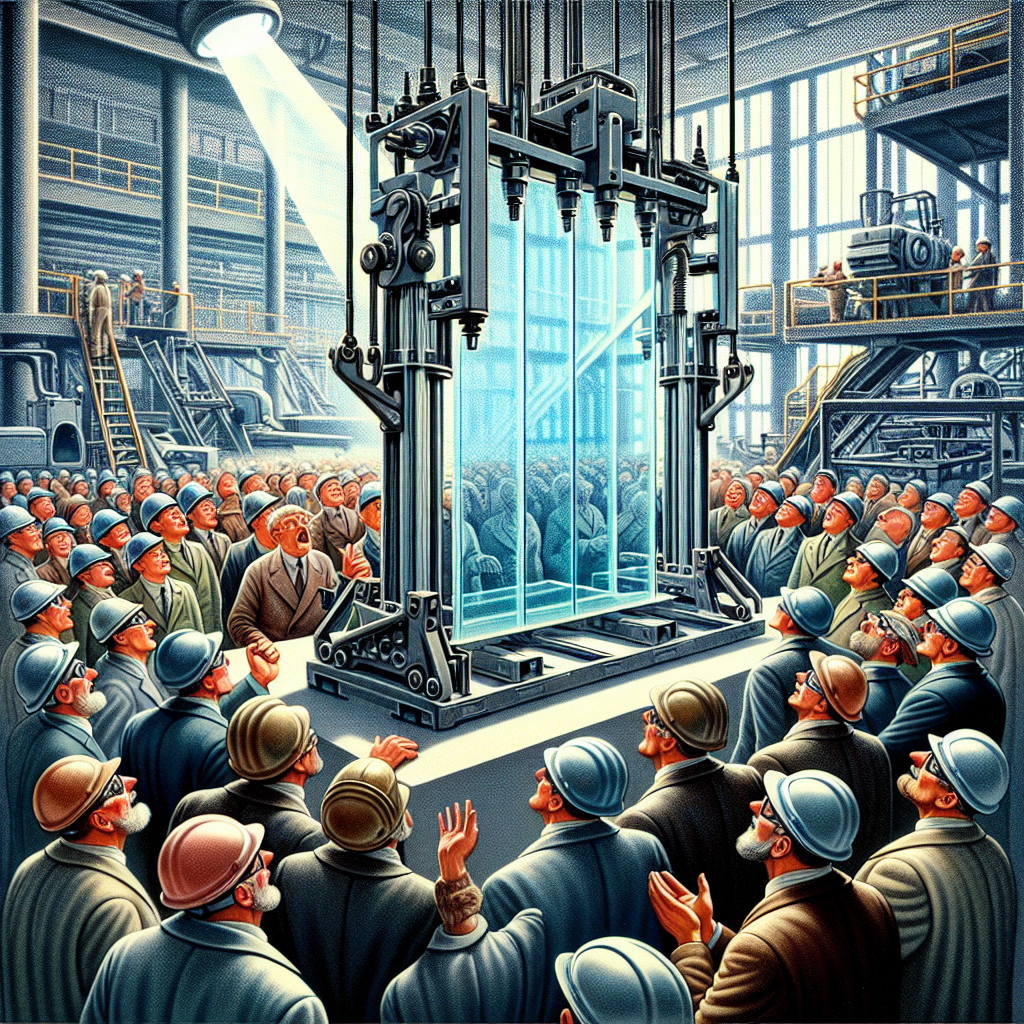

Pneumatic glass lifters have revolutionized the glass industry, providing increased efficiency and safety in glass handling. These innovative devices have become a game-changer, replacing traditional methods of glass lifting and offering numerous benefits to glass manufacturers, installers, and other professionals in the industry.

One of the key advantages of pneumatic glass lifters is their ability to handle heavy loads with ease. Traditional methods of glass lifting often required multiple workers to manually lift and transport heavy glass sheets, which not only posed a risk to their safety but also slowed down the overall process. With pneumatic glass lifters, a single operator can effortlessly lift and move large glass sheets, significantly reducing the time and effort required for glass handling.

Moreover, pneumatic glass lifters offer enhanced safety features that minimize the risk of accidents and injuries. These devices are equipped with suction cups that securely grip the glass, preventing it from slipping or falling during transportation. The suction cups are designed to distribute the weight evenly, ensuring a stable and secure grip on the glass. This eliminates the need for workers to physically hold the glass, reducing the risk of strain or dropping accidents.

In addition to increased efficiency and safety, pneumatic glass lifters also provide versatility in glass handling. These devices can be easily adjusted to accommodate different sizes and shapes of glass, making them suitable for a wide range of applications. Whether it’s lifting large glass panels for architectural purposes or handling delicate glassware in a manufacturing setting, pneumatic glass lifters offer the flexibility needed to meet various requirements.

Furthermore, pneumatic glass lifters are designed to minimize damage to the glass during handling. The suction cups are made from materials that are gentle on the glass surface, preventing scratches or other forms of damage. This is particularly important in industries where the quality of the glass is crucial, such as in the production of high-end glass products or in the installation of glass in architectural projects.

Another advantage of pneumatic glass lifters is their ease of use. These devices are user-friendly and require minimal training to operate. The controls are intuitive, allowing operators to quickly learn how to maneuver the glass lifter with precision and accuracy. This not only saves time but also reduces the risk of errors or accidents caused by inexperienced operators.

In conclusion, pneumatic glass lifters have transformed the glass industry by offering increased efficiency and safety in glass handling. These devices have revolutionized the way glass is lifted and transported, replacing traditional methods that were time-consuming and potentially hazardous. With their ability to handle heavy loads, enhanced safety features, versatility, and ease of use, pneumatic glass lifters have become an indispensable tool for glass manufacturers, installers, and other professionals in the industry. As the demand for glass continues to grow, the adoption of pneumatic glass lifters is expected to increase, further improving the efficiency and safety of glass handling processes.

How Pneumatic Glass Lifters Revolutionize the Glass Installation Process

Pneumatic glass lifters have emerged as a game-changer in the glass industry, revolutionizing the glass installation process. These innovative devices have transformed the way glass is handled, making it safer, more efficient, and less labor-intensive. In this section, we will explore how pneumatic glass lifters have revolutionized the glass installation process.

One of the key advantages of pneumatic glass lifters is their ability to lift and transport heavy glass panels with ease. Traditionally, glass installation required a team of workers to manually lift and maneuver large glass panels, which was not only physically demanding but also posed a significant risk of injury. Pneumatic glass lifters have eliminated this risk by providing a safe and efficient solution for handling heavy glass panels.

These lifters utilize the power of compressed air to create a vacuum seal between the lifter and the glass panel. This vacuum seal allows the lifter to securely grip the glass, enabling it to be lifted and moved effortlessly. The use of pneumatic glass lifters has significantly reduced the physical strain on workers, minimizing the risk of back injuries and other musculoskeletal disorders associated with manual lifting.

Furthermore, pneumatic glass lifters have greatly improved the efficiency of the glass installation process. With traditional methods, the installation of large glass panels was a time-consuming task that required careful coordination and precise positioning. Pneumatic glass lifters have simplified this process by providing precise control over the movement of glass panels.

These lifters are equipped with adjustable suction cups that can be positioned to match the size and shape of the glass panel. This allows for precise placement and alignment, ensuring a perfect fit every time. The ability to easily adjust the position of the glass panel also allows for quick and efficient installation, saving both time and effort.

In addition to their efficiency, pneumatic glass lifters have also improved the safety of the glass installation process. The vacuum seal created by these lifters ensures a secure grip on the glass panel, eliminating the risk of it slipping or falling during installation. This not only protects the glass from damage but also prevents potential injuries to workers or bystanders.

Moreover, pneumatic glass lifters are equipped with safety features such as audible alarms and visual indicators that alert operators to any potential issues or malfunctions. This allows for immediate action to be taken, minimizing the risk of accidents or damage to the glass.

Overall, pneumatic glass lifters have revolutionized the glass installation process by providing a safe, efficient, and reliable solution for handling and installing glass panels. Their ability to lift and transport heavy glass with ease, along with their precise control and safety features, have made them an indispensable tool in the glass industry.

As the demand for glass continues to grow, pneumatic glass lifters will undoubtedly play a crucial role in meeting the industry’s needs. Their ability to streamline the installation process, reduce labor costs, and improve safety make them a valuable asset for glass manufacturers, contractors, and installers alike. With their game-changing capabilities, pneumatic glass lifters have truly transformed the glass industry.

The Advantages of Using Pneumatic Glass Lifters in the Glass Manufacturing Industry

Pneumatic Glass Lifters: A Game-Changer in the Glass Industry

The glass manufacturing industry has seen significant advancements in technology over the years, and one such innovation that has revolutionized the way glass is handled and transported is the pneumatic glass lifter. These powerful machines have become a game-changer in the industry, offering numerous advantages that have made them an indispensable tool for glass manufacturers.

One of the primary advantages of using pneumatic glass lifters is their ability to handle heavy loads with ease. Glass sheets can be extremely heavy and fragile, making them challenging to lift and transport safely. However, pneumatic glass lifters are designed to handle these heavy loads effortlessly, thanks to their powerful suction cups and pneumatic lifting mechanisms. This not only reduces the risk of accidents and injuries but also increases productivity by allowing for faster and more efficient handling of glass sheets.

Another significant advantage of pneumatic glass lifters is their versatility. These machines can be used to lift and transport glass sheets of various sizes and shapes, making them suitable for a wide range of glass manufacturing applications. Whether it’s large glass panels for architectural purposes or small glass components for electronic devices, pneumatic glass lifters can handle them all. This versatility eliminates the need for multiple lifting devices, saving both time and money for glass manufacturers.

In addition to their versatility, pneumatic glass lifters also offer precise control and maneuverability. The suction cups on these machines can be adjusted to fit the size and shape of the glass sheet, ensuring a secure grip and minimizing the risk of damage during lifting and transportation. Furthermore, pneumatic glass lifters can be easily maneuvered in tight spaces, allowing for efficient handling even in confined areas. This level of control and maneuverability is crucial in the glass manufacturing industry, where precision and accuracy are paramount.

One of the most significant advantages of using pneumatic glass lifters is the enhanced safety they provide. Traditional methods of lifting and transporting glass sheets, such as manual handling or the use of cranes and forklifts, can be risky and prone to accidents. Pneumatic glass lifters eliminate these risks by providing a secure and stable lifting mechanism that minimizes the chances of glass breakage or injuries to workers. This not only ensures the safety of employees but also reduces the risk of costly damages to glass products.

Furthermore, pneumatic glass lifters are designed to be user-friendly and easy to operate. They require minimal training and can be operated by a single person, reducing the need for additional manpower. This not only saves labor costs but also increases efficiency and productivity in the glass manufacturing process.

In conclusion, pneumatic glass lifters have become a game-changer in the glass industry due to their numerous advantages. From their ability to handle heavy loads with ease to their versatility, precise control, and enhanced safety features, these machines have transformed the way glass is handled and transported in the manufacturing process. With their user-friendly design and cost-saving benefits, pneumatic glass lifters have become an indispensable tool for glass manufacturers, allowing them to increase productivity, reduce risks, and deliver high-quality glass products to their customers.