Benefits of Using Pneumatic Glass Lifters in Construction Projects

Pneumatic Glass Lifters: A Comprehensive Overview

Benefits of Using Pneumatic Glass Lifters in Construction Projects

Construction projects often involve the installation of large glass panels, which can be heavy and difficult to handle. In the past, manual labor was required to lift and position these panels, posing a risk to workers and potentially causing damage to the glass. However, with the advent of pneumatic glass lifters, these challenges have been significantly mitigated, making them an invaluable tool in the construction industry.

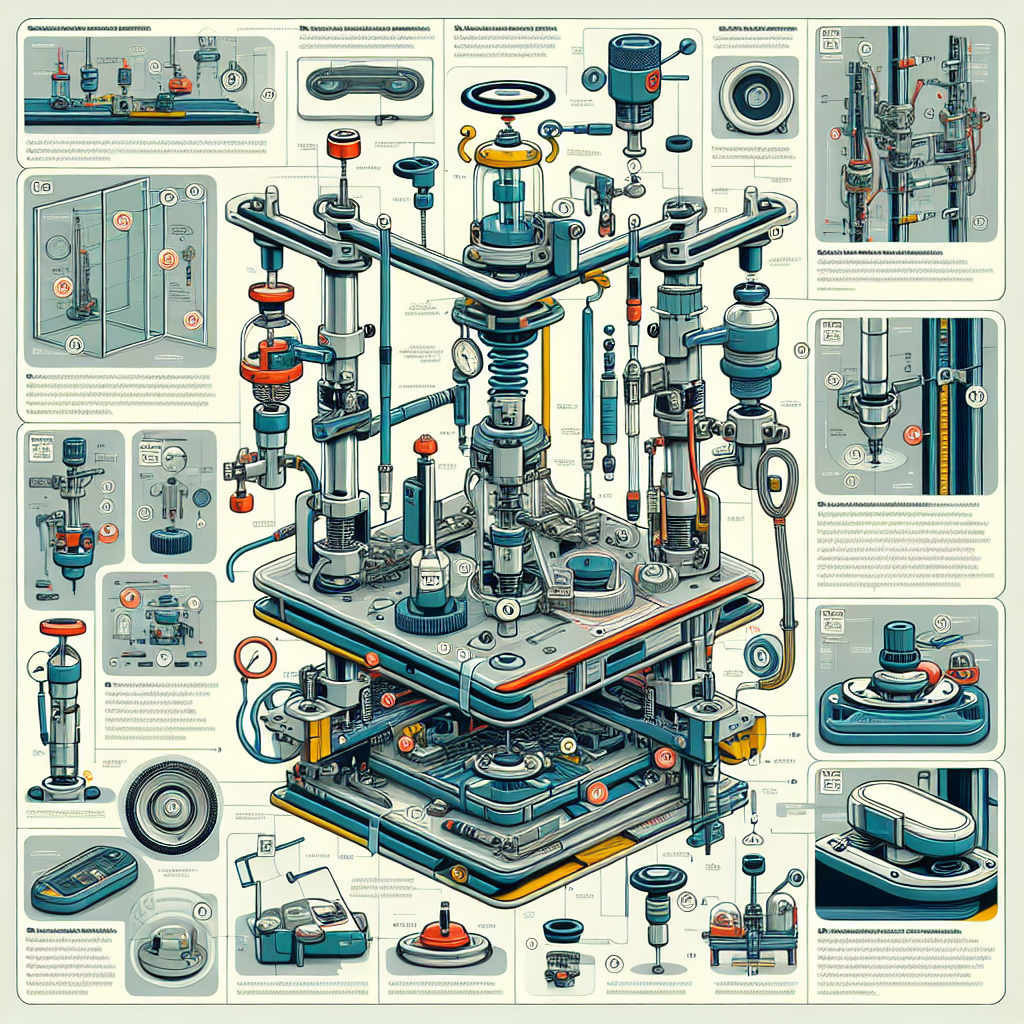

One of the key benefits of using pneumatic glass lifters is their ability to lift heavy glass panels with ease. These lifters are equipped with powerful suction cups that create a vacuum seal on the glass surface, allowing them to securely grip and lift even the heaviest panels. This eliminates the need for manual lifting, reducing the risk of injuries to workers and ensuring the safety of the glass panels.

Furthermore, pneumatic glass lifters offer a high level of precision and control during the lifting process. They are designed with adjustable suction cups that can be positioned to match the size and shape of the glass panel, ensuring a secure grip. This level of control allows for accurate placement of the glass, minimizing the risk of damage and ensuring a perfect fit.

Another advantage of using pneumatic glass lifters is their versatility. These lifters can be used for a wide range of glass installation tasks, including lifting, tilting, rotating, and transporting glass panels. This versatility makes them suitable for various construction projects, from small-scale residential installations to large commercial buildings.

In addition to their versatility, pneumatic glass lifters are also highly efficient. They are powered by compressed air, which is readily available on most construction sites. This eliminates the need for additional power sources, such as electricity or batteries, making them cost-effective and environmentally friendly.

Moreover, pneumatic glass lifters are designed to be user-friendly. They are equipped with intuitive controls that allow operators to easily maneuver the lifters and adjust the suction cups as needed. This ease of use reduces the learning curve for operators, enabling them to quickly and efficiently complete glass installation tasks.

Furthermore, the use of pneumatic glass lifters can significantly reduce the time required for glass installation. The lifters’ ability to lift and position glass panels quickly and accurately allows for faster project completion. This not only saves time but also reduces labor costs, making them a cost-effective solution for construction projects.

Lastly, pneumatic glass lifters contribute to the overall quality of glass installations. The precise control and secure grip provided by these lifters ensure that glass panels are installed correctly, minimizing the risk of breakage or damage. This results in a finished product that meets the highest standards of quality and aesthetics.

In conclusion, pneumatic glass lifters offer numerous benefits for construction projects involving glass installations. Their ability to lift heavy panels with ease, provide precise control, and offer versatility make them an invaluable tool in the construction industry. Additionally, their efficiency, user-friendliness, and contribution to the overall quality of glass installations make them a cost-effective and reliable solution. By incorporating pneumatic glass lifters into construction projects, contractors can enhance safety, efficiency, and the overall success of their projects.

How Pneumatic Glass Lifters Improve Efficiency and Safety in Glass Installation

Pneumatic glass lifters have revolutionized the glass installation industry, providing a comprehensive solution that improves both efficiency and safety. These innovative devices utilize the power of compressed air to lift and transport heavy glass panels, eliminating the need for manual lifting and reducing the risk of accidents and injuries.

One of the key advantages of pneumatic glass lifters is their ability to handle large and heavy glass panels with ease. Traditional methods of glass installation often required multiple workers to manually lift and position these panels, which not only increased the risk of accidents but also slowed down the installation process. With pneumatic glass lifters, a single operator can effortlessly lift and maneuver even the heaviest glass panels, significantly reducing the time and effort required for installation.

In addition to improving efficiency, pneumatic glass lifters also enhance safety in glass installation. The use of compressed air eliminates the need for workers to physically lift and carry heavy glass panels, reducing the risk of strains, sprains, and other musculoskeletal injuries. This is particularly important in the construction industry, where manual lifting tasks are a leading cause of workplace injuries. By automating the lifting process, pneumatic glass lifters help protect workers from these hazards and create a safer working environment.

Furthermore, pneumatic glass lifters are designed with safety features that ensure the secure handling of glass panels. These devices are equipped with suction cups or vacuum pads that create a strong grip on the glass surface, preventing slippage during lifting and transportation. Some models also feature additional safety mechanisms, such as audible alarms or visual indicators, to alert operators in case of any issues or malfunctions. These safety features provide peace of mind to both operators and project managers, knowing that the glass panels are being handled securely and reliably.

Another advantage of pneumatic glass lifters is their versatility. These devices can be used for a wide range of glass installation applications, including windows, doors, curtain walls, and glass partitions. They can handle various shapes and sizes of glass panels, adapting to the specific requirements of each project. This versatility makes pneumatic glass lifters a valuable investment for glass installation companies, as they can be used across multiple projects and applications, maximizing their return on investment.

Moreover, pneumatic glass lifters are designed to be user-friendly and easy to operate. Most models feature intuitive controls and ergonomic handles, allowing operators to quickly learn and master their operation. This reduces the need for extensive training and minimizes the risk of operator errors. Additionally, the compact and portable design of pneumatic glass lifters enables easy transportation and maneuverability on job sites, further enhancing their usability and convenience.

In conclusion, pneumatic glass lifters offer a comprehensive solution for improving efficiency and safety in glass installation. These devices eliminate the need for manual lifting, reducing the risk of injuries and increasing productivity. With their versatile capabilities and user-friendly design, pneumatic glass lifters have become an essential tool for glass installation companies, providing a reliable and efficient method for handling heavy glass panels. By investing in pneumatic glass lifters, companies can enhance their operations, protect their workers, and deliver high-quality glass installations.

Factors to Consider When Choosing the Right Pneumatic Glass Lifter for Your Project

Pneumatic Glass Lifters: A Comprehensive Overview

Factors to Consider When Choosing the Right Pneumatic Glass Lifter for Your Project

When it comes to lifting and moving heavy glass panels, pneumatic glass lifters have become an essential tool for many construction and manufacturing projects. These lifters use compressed air to create a vacuum seal, allowing for safe and efficient handling of glass. However, with so many options available on the market, it can be overwhelming to choose the right pneumatic glass lifter for your specific project. In this article, we will discuss the key factors to consider when making this important decision.

First and foremost, it is crucial to assess the weight capacity of the pneumatic glass lifter. Different lifters have varying weight limits, so it is essential to know the weight of the glass panels you will be working with. Choosing a lifter with a capacity that exceeds the weight of your heaviest glass panel is recommended to ensure safety and prevent any accidents or damage.

Another important factor to consider is the size and shape of the glass panels you will be handling. Pneumatic glass lifters come in various configurations, including single-pad lifters, multi-pad lifters, and adjustable lifters. Single-pad lifters are suitable for smaller glass panels, while multi-pad lifters are designed for larger panels. Adjustable lifters offer versatility, allowing you to handle glass panels of different sizes and shapes. Assessing your specific needs and the types of glass panels you will be working with will help you determine the most suitable lifter for your project.

The surface condition of the glass panels is also a crucial consideration. Some pneumatic glass lifters are designed specifically for smooth glass surfaces, while others are equipped with special pads or suction cups to handle textured or frosted glass. It is essential to choose a lifter that is compatible with the surface condition of your glass panels to ensure a secure grip and prevent any damage during lifting and transportation.

Additionally, the lifting height and reach of the pneumatic glass lifter should be taken into account. Depending on the nature of your project, you may need a lifter with a higher lifting height or a longer reach. Some lifters offer adjustable height and reach options, providing flexibility for different applications. Evaluating the specific requirements of your project will help you determine the appropriate lifting height and reach for your pneumatic glass lifter.

Furthermore, it is essential to consider the power source of the lifter. Pneumatic glass lifters can be powered by either an air compressor or a battery. Air-powered lifters are typically more powerful and suitable for heavy-duty applications, while battery-powered lifters offer greater mobility and flexibility. Assessing the availability of power sources at your worksite and the specific needs of your project will help you decide which power source is most suitable for your pneumatic glass lifter.

Lastly, it is crucial to consider the overall quality and reliability of the pneumatic glass lifter. Look for lifters that are made from durable materials and have a proven track record of performance and safety. Reading customer reviews and seeking recommendations from industry professionals can provide valuable insights into the reliability and quality of different lifters.

In conclusion, choosing the right pneumatic glass lifter for your project requires careful consideration of several factors. Assessing the weight capacity, size and shape compatibility, surface condition compatibility, lifting height and reach, power source, and overall quality and reliability will help you make an informed decision. By selecting the most suitable lifter, you can ensure safe and efficient handling of glass panels, contributing to the success of your project.