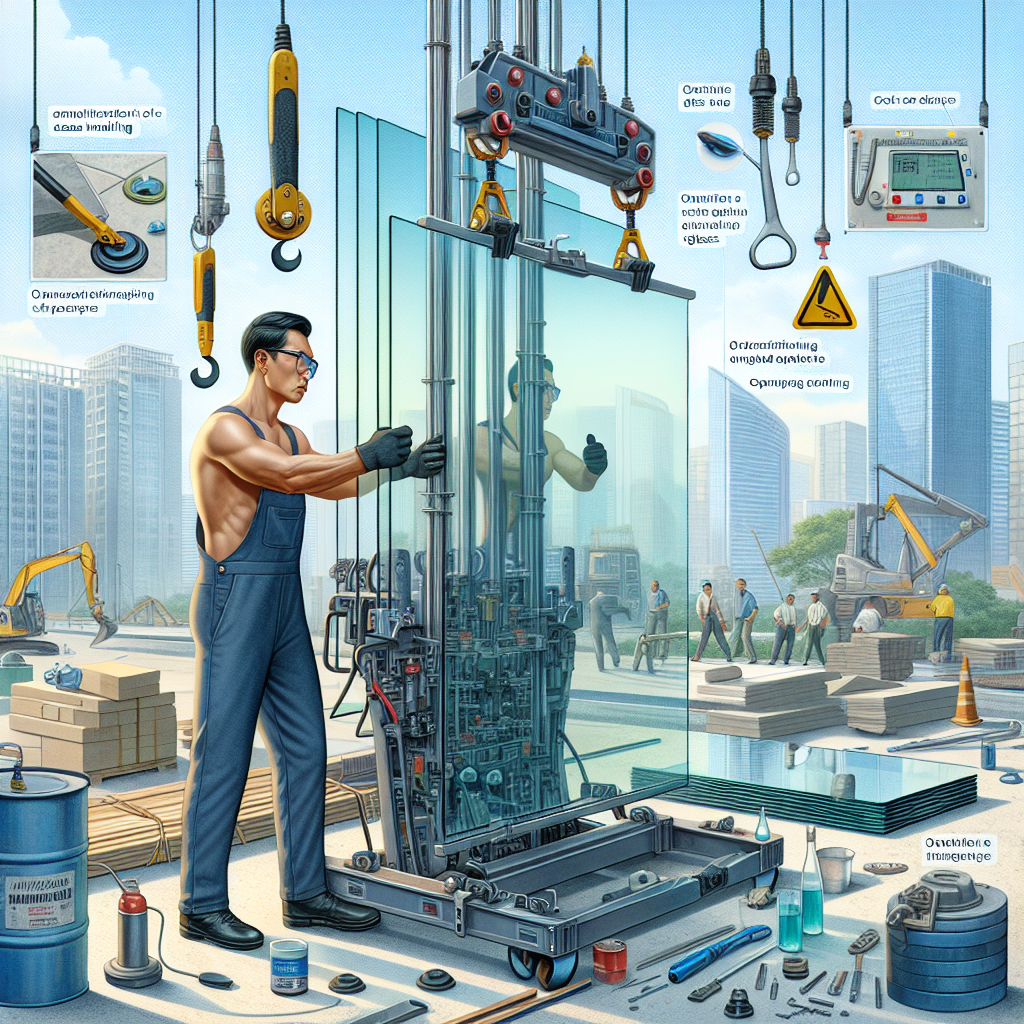

Benefits of Using a Vacuum Glass Lifter for Glass Handling Optimization

Glass handling can be a challenging task, especially when dealing with large and heavy glass panels. Traditional methods of handling glass, such as using suction cups or manual lifting, can be time-consuming, labor-intensive, and even dangerous. However, with the advent of vacuum glass lifters, glass handling has been revolutionized, offering numerous benefits for optimizing the process.

One of the key benefits of using a vacuum glass lifter is the increased efficiency it provides. Unlike traditional methods, which require multiple workers to lift and maneuver glass panels, a vacuum glass lifter can be operated by a single person. This not only saves time but also reduces labor costs, making it a cost-effective solution for glass handling.

In addition to efficiency, a vacuum glass lifter also enhances safety in the workplace. Glass panels are fragile and can easily break or shatter if mishandled. By using a vacuum glass lifter, the risk of accidents and injuries is significantly reduced. The lifter’s suction cups securely grip the glass, preventing it from slipping or falling during transportation. This not only protects the glass but also ensures the safety of the workers involved in the handling process.

Furthermore, a vacuum glass lifter offers versatility in handling different types of glass. Whether it’s flat glass, curved glass, or even textured glass, the lifter’s adjustable suction cups can adapt to various shapes and sizes. This versatility eliminates the need for specialized equipment or additional tools, streamlining the glass handling process and saving both time and money.

Another advantage of using a vacuum glass lifter is its ability to optimize workflow. With traditional methods, the process of lifting and moving glass panels can be slow and cumbersome. However, a vacuum glass lifter allows for quick and easy maneuverability, enabling glass panels to be transported effortlessly from one location to another. This not only speeds up the overall workflow but also minimizes downtime and increases productivity.

Moreover, a vacuum glass lifter reduces the risk of damage to glass panels. Traditional methods of handling glass often involve direct contact with the glass surface, which can lead to scratches, smudges, or other forms of damage. In contrast, a vacuum glass lifter uses suction cups to grip the glass, eliminating the need for direct contact. This gentle handling ensures that the glass remains in pristine condition, free from any blemishes or imperfections.

Lastly, a vacuum glass lifter offers ergonomic benefits for the operators. The lifter is designed with the operator’s comfort in mind, featuring adjustable handles and controls that can be easily operated. This ergonomic design reduces strain and fatigue, allowing operators to work efficiently and comfortably for extended periods.

In conclusion, the benefits of using a vacuum glass lifter for glass handling optimization are numerous. From increased efficiency and safety to versatility and workflow optimization, a vacuum glass lifter offers a cost-effective and practical solution for handling glass panels. With its ability to securely grip different types of glass and minimize the risk of damage, it is a valuable tool for any industry that deals with glass handling. Moreover, its ergonomic design ensures the comfort and well-being of the operators, making it an ideal choice for optimizing glass handling processes.

Key Features to Consider When Choosing a Vacuum Glass Lifter for Glass Handling Optimization

Glass handling can be a challenging task, especially when dealing with large and heavy glass panels. The use of a vacuum glass lifter can greatly optimize the process, making it safer and more efficient. However, choosing the right vacuum glass lifter is crucial to ensure maximum optimization. In this article, we will discuss the key features to consider when selecting a vacuum glass lifter for glass handling optimization.

First and foremost, the lifting capacity of the vacuum glass lifter is of utmost importance. It is essential to choose a lifter that can handle the weight of the glass panels you will be working with. The lifting capacity should be clearly stated by the manufacturer, and it is advisable to choose a lifter with a slightly higher capacity than what you anticipate needing. This will provide a safety margin and prevent any accidents or damage to the glass.

Another important feature to consider is the number and arrangement of suction cups on the lifter. The suction cups are responsible for creating a vacuum seal with the glass panel, ensuring a secure grip. The more suction cups a lifter has, the better the weight distribution and stability. Additionally, the arrangement of the suction cups should be designed to evenly distribute the weight of the glass panel. This will prevent any imbalances and reduce the risk of the glass slipping or breaking during handling.

The material of the suction cups is also worth considering. Silicone suction cups are commonly used due to their excellent grip and durability. They are resistant to wear and tear, and they can withstand high temperatures without losing their effectiveness. It is advisable to choose a vacuum glass lifter with high-quality silicone suction cups to ensure optimal performance and longevity.

Furthermore, the power source of the vacuum glass lifter is an important factor to consider. Some lifters are powered by electricity, while others are powered by compressed air. Electric lifters are generally more convenient and easier to use, as they do not require any additional equipment. However, they may not be suitable for certain environments where electricity is not readily available. In such cases, a compressed air-powered lifter would be a better option.

Additionally, the control system of the vacuum glass lifter should be user-friendly and intuitive. It should allow for easy operation and provide clear feedback on the status of the vacuum seal. Some lifters come with advanced features such as automatic release and adjustable suction force, which can further optimize the glass handling process. These features allow for precise control and customization, ensuring maximum efficiency and safety.

Lastly, it is important to consider the overall build quality and safety features of the vacuum glass lifter. The lifter should be made of high-quality materials that can withstand heavy use and harsh conditions. It should also be equipped with safety mechanisms such as audible alarms and visual indicators to alert the operator in case of any issues with the vacuum seal. Additionally, the lifter should have a reliable and secure attachment mechanism to the lifting equipment, ensuring stability and preventing any accidents.

In conclusion, choosing the right vacuum glass lifter is crucial for optimizing glass handling. Key features to consider include lifting capacity, suction cup arrangement and material, power source, control system, build quality, and safety features. By carefully evaluating these features, you can select a vacuum glass lifter that meets your specific needs and ensures safe and efficient glass handling.

Best Practices for Safe and Efficient Glass Handling with a Vacuum Glass Lifter

Glass handling can be a challenging task, especially when dealing with large and heavy glass panels. The use of a vacuum glass lifter can greatly optimize the process, making it safer and more efficient. In this article, we will discuss the best practices for safe and efficient glass handling with a vacuum glass lifter.

First and foremost, it is crucial to ensure that the vacuum glass lifter is in good working condition. Regular maintenance and inspections should be conducted to identify any potential issues or malfunctions. This will help prevent accidents and ensure the lifter’s optimal performance.

Before using the vacuum glass lifter, it is important to assess the weight and dimensions of the glass panel. This information will help determine the appropriate lifter capacity and ensure that the lifter is capable of safely handling the glass. It is also essential to check the surface condition of the glass, as any defects or irregularities may affect the lifter’s ability to create a vacuum seal.

When operating the vacuum glass lifter, it is crucial to follow the manufacturer’s instructions and guidelines. This includes properly attaching the lifter to the glass panel and ensuring a secure vacuum seal. It is recommended to use multiple suction cups to distribute the weight evenly and minimize the risk of the glass panel slipping or breaking.

Transitional phrase: In addition to proper attachment, it is important to handle the glass panel with care. When lifting or moving the glass, it is advisable to do so slowly and smoothly, avoiding any sudden movements or jerks. This will help maintain the stability of the glass and prevent any potential damage.

Transitional phrase: Furthermore, it is essential to have a clear communication system in place when working with a team. This can be achieved through the use of hand signals or two-way radios, ensuring that everyone is aware of the lifting and movement operations. Effective communication is crucial to prevent accidents and coordinate the handling process efficiently.

Transitional phrase: Another important aspect of glass handling with a vacuum glass lifter is the use of proper personal protective equipment (PPE). This includes safety gloves, goggles, and steel-toed boots. PPE will help protect the workers from potential injuries and ensure their safety throughout the handling process.

Transitional phrase: Additionally, it is important to consider the environmental conditions when using a vacuum glass lifter. Extreme temperatures, high winds, or wet surfaces can affect the lifter’s performance and increase the risk of accidents. It is advisable to assess the weather conditions and take appropriate measures, such as using additional securing devices or rescheduling the glass handling if necessary.

Transitional phrase: Lastly, it is crucial to have a contingency plan in place in case of any emergencies or equipment failures. This may include having backup equipment available or having trained personnel who can quickly respond to any unforeseen situations. Being prepared for emergencies will help minimize downtime and ensure the safety of everyone involved.

In conclusion, optimizing glass handling with a vacuum glass lifter requires adherence to best practices for safe and efficient operations. Regular maintenance, proper attachment, careful handling, effective communication, the use of PPE, consideration of environmental conditions, and having a contingency plan are all essential elements to ensure a successful glass handling process. By following these guidelines, glass handling can be made safer and more efficient, reducing the risk of accidents and improving overall productivity.