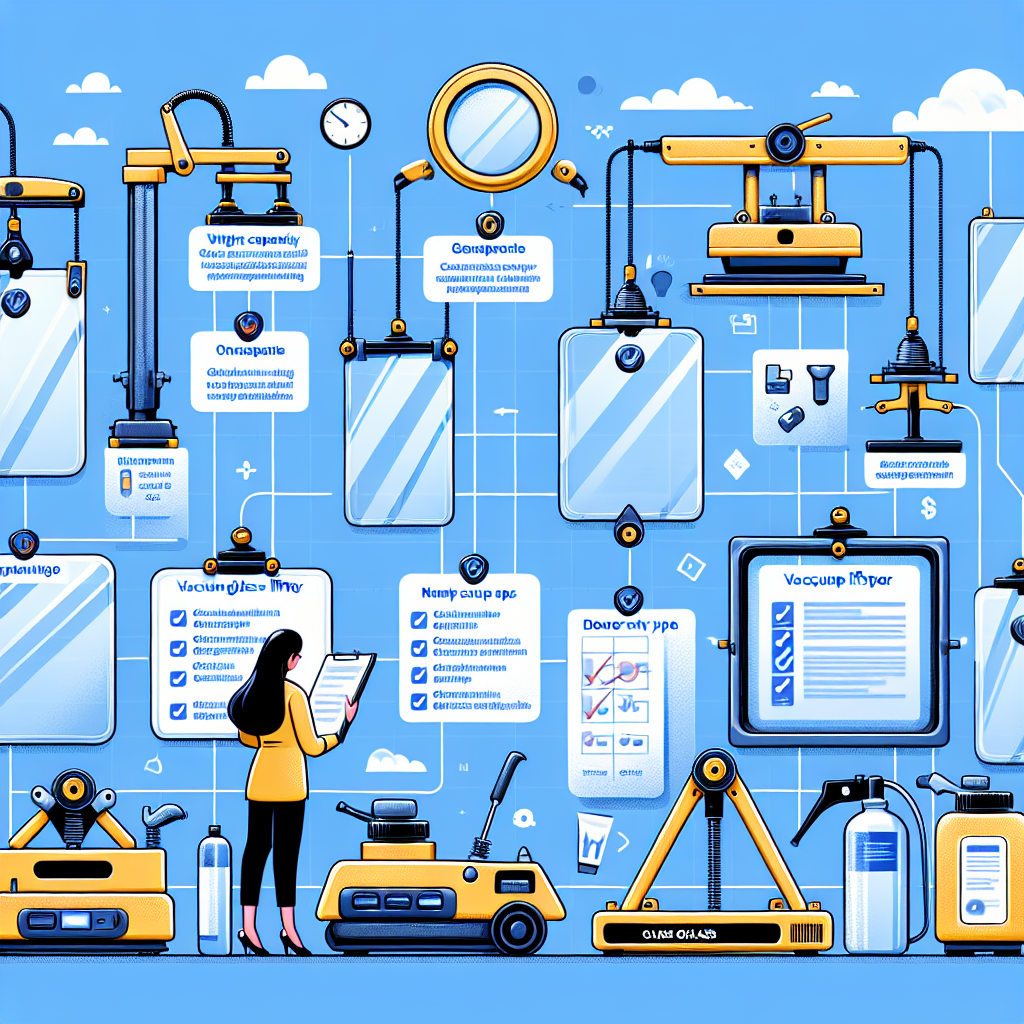

Factors to Consider When Selecting a Vacuum Glass Lifter

When it comes to selecting a vacuum glass lifter, there are several factors that need to be taken into consideration. Choosing the right lifter for your needs is crucial to ensure efficiency and safety in your glass handling operations. In this article, we will discuss the key factors that you should consider when selecting a vacuum glass lifter.

First and foremost, you need to consider the weight capacity of the lifter. Different lifters have different weight capacities, and it is important to choose one that can handle the weight of the glass you will be lifting. It is always better to choose a lifter with a higher weight capacity than you actually need, as this will provide an extra margin of safety.

Another important factor to consider is the size and shape of the glass. Some lifters are designed specifically for flat glass, while others can handle curved or irregularly shaped glass. It is important to choose a lifter that is compatible with the type of glass you will be working with. Additionally, you should consider the size of the glass and ensure that the lifter has a suction cup configuration that can securely hold the glass in place.

The type of surface you will be working on is also an important consideration. Some lifters are designed for smooth surfaces, while others can handle rough or textured surfaces. If you will be working on a variety of surfaces, it is important to choose a lifter that is versatile and can adapt to different conditions.

Next, you should consider the power source of the lifter. Some lifters are powered by electricity, while others are powered by compressed air. Electric lifters are generally more convenient and easier to use, but they may not be suitable for all applications. Compressed air lifters, on the other hand, are more suitable for heavy-duty applications and can provide a higher lifting capacity.

In addition to the power source, you should also consider the control system of the lifter. Some lifters have manual controls, while others have automated controls. Manual controls require the operator to manually activate and deactivate the suction, while automated controls can provide more precise and consistent suction control. The choice between manual and automated controls depends on your specific needs and preferences.

Lastly, you should consider the safety features of the lifter. Safety should always be a top priority when working with glass, and it is important to choose a lifter that has safety features such as audible and visual alarms, emergency stop buttons, and overload protection. These features can help prevent accidents and ensure the safety of both the operator and the glass being lifted.

In conclusion, choosing the right vacuum glass lifter requires careful consideration of several factors. These include the weight capacity, size and shape compatibility, surface compatibility, power source, control system, and safety features. By taking these factors into account, you can select a lifter that is best suited to your specific needs and ensure efficient and safe glass handling operations.

Different Types of Vacuum Glass Lifters and Their Applications

Different Types of Vacuum Glass Lifters and Their Applications

When it comes to choosing the right vacuum glass lifter for your needs, it’s important to understand the different types available and their specific applications. Vacuum glass lifters are a valuable tool in the construction and manufacturing industries, as they provide a safe and efficient way to handle large sheets of glass. In this article, we will explore the various types of vacuum glass lifters and their uses.

One of the most common types of vacuum glass lifters is the manual lifter. This type of lifter is operated by hand and is typically used for smaller glass panels or windows. Manual lifters are lightweight and portable, making them ideal for jobs that require mobility. They are also easy to operate, with a simple pump mechanism that creates suction to hold the glass in place. However, manual lifters have their limitations, as they can only handle relatively small loads and require physical effort from the operator.

For larger glass panels or heavier loads, a powered vacuum glass lifter is a better option. These lifters are equipped with an electric or pneumatic pump that creates suction, eliminating the need for manual pumping. Powered lifters are capable of handling much larger loads and are more efficient for heavy-duty applications. They also offer additional features such as adjustable suction cups and tilt functions, allowing for greater flexibility and precision in lifting and positioning glass.

In addition to manual and powered lifters, there are also specialized vacuum glass lifters designed for specific applications. For instance, there are lifters specifically designed for curved glass, which require a different suction cup configuration to accommodate the unique shape of the glass. These lifters are often used in the automotive and architectural industries, where curved glass is commonly used in the design of vehicles and buildings.

Another specialized type of vacuum glass lifter is the dual-circuit lifter. This lifter is equipped with two separate vacuum circuits, allowing for increased safety and stability. In the event that one circuit fails, the other circuit will still maintain suction, preventing the glass from falling. Dual-circuit lifters are commonly used in high-risk applications where the safety of personnel and the integrity of the glass are of utmost importance.

When choosing a vacuum glass lifter, it’s important to consider the specific requirements of your application. Factors such as the size and weight of the glass, the type of surface it will be lifted from, and the environment in which it will be used should all be taken into account. Additionally, it’s important to ensure that the lifter you choose is compliant with safety regulations and standards.

In conclusion, choosing the right vacuum glass lifter for your needs requires careful consideration of the different types available and their specific applications. Whether you require a manual lifter for smaller glass panels or a powered lifter for heavy-duty applications, there is a lifter out there to suit your needs. By understanding the various options and their features, you can make an informed decision and ensure the safe and efficient handling of glass in your industry.

Tips for Maintaining and Extending the Lifespan of Your Vacuum Glass Lifter

Tips for Maintaining and Extending the Lifespan of Your Vacuum Glass Lifter

When it comes to choosing the right vacuum glass lifter for your needs, there are several factors to consider. However, once you have made your selection, it is equally important to properly maintain and care for your lifter to ensure its longevity and optimal performance. In this article, we will provide you with some valuable tips on how to maintain and extend the lifespan of your vacuum glass lifter.

First and foremost, it is crucial to regularly inspect your lifter for any signs of wear and tear. This includes checking the suction cups for any cracks or damage, as well as examining the vacuum pump and hoses for any leaks or loose connections. By conducting routine inspections, you can identify and address any potential issues before they escalate and cause further damage to your lifter.

In addition to regular inspections, it is essential to clean your vacuum glass lifter after each use. This involves removing any debris or dirt that may have accumulated on the suction cups or other parts of the lifter. A soft cloth or sponge, along with a mild detergent, can be used to gently clean the lifter. Avoid using abrasive materials or harsh chemicals, as they can damage the lifter’s components.

Furthermore, it is important to store your vacuum glass lifter properly when it is not in use. This means keeping it in a clean and dry environment, away from extreme temperatures or direct sunlight. Additionally, it is advisable to store the lifter in a secure location to prevent any accidental damage or unauthorized use.

Another crucial aspect of maintaining your vacuum glass lifter is to regularly lubricate its moving parts. This includes the hinges, joints, and other mechanisms that enable the lifter to function smoothly. Applying a small amount of lubricant, such as silicone spray or oil, can help reduce friction and ensure the lifter operates efficiently.

Moreover, it is recommended to follow the manufacturer’s guidelines and recommendations for maintenance and servicing. This may include periodic inspections by a qualified technician or replacing certain components after a certain number of hours of use. By adhering to these guidelines, you can ensure that your lifter remains in optimal condition and minimize the risk of any unexpected breakdowns or malfunctions.

Lastly, it is crucial to use your vacuum glass lifter within its specified weight capacity. Overloading the lifter can put excessive strain on its components and lead to premature wear and tear. Always refer to the lifter’s user manual or consult with the manufacturer to determine the maximum weight it can safely handle.

In conclusion, maintaining and extending the lifespan of your vacuum glass lifter requires regular inspections, proper cleaning, appropriate storage, lubrication of moving parts, adherence to manufacturer’s guidelines, and using the lifter within its weight capacity. By following these tips, you can ensure that your lifter remains in optimal condition, providing you with reliable and efficient performance for years to come.