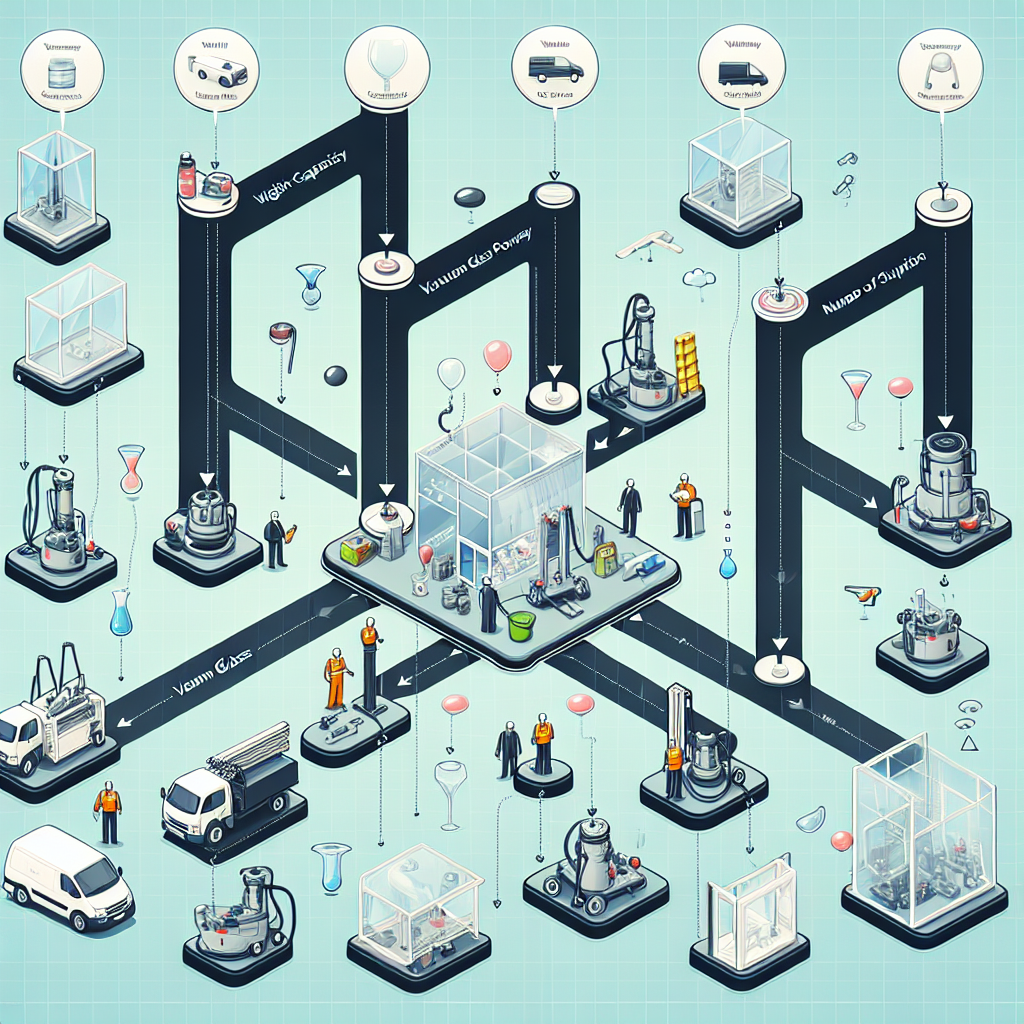

Key Factors to Consider When Selecting a Vacuum Glass Lifter for Your Business

When it comes to choosing the right vacuum glass lifter for your business, there are several key factors that you need to consider. This article will guide you through the process of selecting the best vacuum glass lifter for your specific needs.

First and foremost, you need to consider the weight capacity of the vacuum glass lifter. This is perhaps the most important factor to consider, as it will determine whether or not the lifter is capable of handling the glass panels that you work with. It is crucial to choose a lifter that has a weight capacity that exceeds the weight of the heaviest glass panel that you will be lifting. This will ensure that the lifter is able to handle the load safely and efficiently.

Another important factor to consider is the size and shape of the glass panels that you will be working with. Different vacuum glass lifters are designed to handle different sizes and shapes of glass panels. It is important to choose a lifter that is specifically designed to handle the size and shape of the glass panels that you work with. This will ensure that the lifter is able to securely grip the glass panels and lift them without any issues.

In addition to the weight capacity and size/shape compatibility, you also need to consider the type of vacuum system that the lifter uses. There are two main types of vacuum systems: air-powered and electric-powered. Air-powered vacuum lifters are typically more affordable and easier to maintain, but they may not be as powerful as electric-powered lifters. Electric-powered vacuum lifters, on the other hand, are generally more powerful and can handle heavier loads, but they tend to be more expensive and require more maintenance.

Furthermore, you need to consider the safety features of the vacuum glass lifter. Safety should always be a top priority when working with heavy glass panels. Look for lifters that have features such as automatic shut-off valves, audible alarms, and visual indicators to ensure that the lifter is operating safely. Additionally, consider lifters that have backup power systems in case of power failure, as this will prevent any accidents or damage to the glass panels.

Lastly, you should also consider the overall quality and durability of the vacuum glass lifter. Look for lifters that are made from high-quality materials and have a solid construction. This will ensure that the lifter is able to withstand the rigors of daily use and last for a long time. Additionally, consider lifters that come with a warranty, as this will provide you with peace of mind knowing that you are protected against any defects or malfunctions.

In conclusion, choosing the right vacuum glass lifter for your business requires careful consideration of several key factors. These include the weight capacity, size/shape compatibility, type of vacuum system, safety features, and overall quality and durability. By taking the time to evaluate these factors, you can ensure that you select a lifter that meets your specific needs and provides you with reliable and efficient glass lifting capabilities.

Understanding the Different Types of Vacuum Glass Lifters and Their Applications

Understanding the Different Types of Vacuum Glass Lifters and Their Applications

When it comes to choosing the right vacuum glass lifter for your business, it is important to understand the different types available and their specific applications. Vacuum glass lifters are essential tools for handling glass panels, windows, and other smooth surfaces in various industries such as construction, manufacturing, and transportation. By understanding the different types of vacuum glass lifters and their applications, you can make an informed decision that meets your business needs.

One of the most common types of vacuum glass lifters is the manual lifter. As the name suggests, this type of lifter requires manual operation and is suitable for smaller glass panels or windows. Manual lifters are often portable and easy to use, making them ideal for smaller businesses or projects that do not require heavy lifting. They are also cost-effective and do not require any additional power source, making them a popular choice for many businesses.

For larger glass panels or windows, a powered vacuum glass lifter may be more suitable. These lifters are equipped with a motor or pump that creates the necessary suction force to lift and transport heavy glass panels. Powered lifters are often mounted on cranes or other machinery, allowing for efficient and safe lifting of large glass panels. They are commonly used in construction projects or manufacturing facilities where heavy lifting is required.

In addition to manual and powered lifters, there are also specialized vacuum glass lifters designed for specific applications. For instance, there are lifters with adjustable suction cups that can accommodate different sizes and shapes of glass panels. This flexibility is particularly useful in industries where glass panels come in various dimensions. There are also lifters with tilting or rotating mechanisms, allowing for precise positioning of glass panels during installation. These specialized lifters are often used in architectural projects or high-end glass installations.

Another important consideration when choosing a vacuum glass lifter is the weight capacity. Different lifters have different weight capacities, and it is crucial to select one that can handle the weight of the glass panels you will be working with. Exceeding the weight capacity of a lifter can lead to accidents or damage to the glass panels, so it is essential to choose a lifter that can safely handle the load.

Furthermore, it is important to consider the safety features of a vacuum glass lifter. Look for lifters with features such as audible alarms or visual indicators that alert the operator if the suction is compromised. Some lifters also have backup power sources or fail-safe mechanisms to prevent accidents in case of power failure. Safety should always be a top priority when choosing a vacuum glass lifter for your business.

In conclusion, choosing the right vacuum glass lifter for your business requires an understanding of the different types available and their specific applications. Whether you need a manual lifter for smaller glass panels or a powered lifter for heavy lifting, there are options to suit your needs. Consider factors such as weight capacity and safety features to ensure that you select a lifter that meets your business requirements. By making an informed decision, you can enhance efficiency and safety in handling glass panels, ultimately benefiting your business.

Tips for Evaluating the Performance and Safety Features of Vacuum Glass Lifters

When it comes to choosing the right vacuum glass lifter for your business, there are several factors to consider. One of the most important aspects to evaluate is the performance of the lifter. You want a machine that can handle the weight and size of the glass you will be working with. Additionally, you want a lifter that can operate efficiently and effectively, saving you time and effort.

To evaluate the performance of a vacuum glass lifter, you should first consider its lifting capacity. This refers to the maximum weight that the lifter can safely handle. It is crucial to choose a lifter with a lifting capacity that matches the weight of the glass you will be working with. If the lifter is not capable of handling the weight, it can lead to accidents and damage to the glass.

Another performance factor to consider is the lifter’s suction power. The suction power determines how securely the lifter can hold onto the glass. A strong suction power is essential to ensure that the glass does not slip or fall during lifting. It is advisable to choose a lifter with adjustable suction power, as this allows you to customize the level of grip based on the specific requirements of each glass piece.

In addition to performance, safety features are also crucial when choosing a vacuum glass lifter. Safety should always be a top priority in any business, and this is especially true when working with heavy and fragile materials like glass. One important safety feature to look for is a vacuum loss warning system. This system alerts the operator if the vacuum seal is compromised, preventing accidents and potential damage to the glass.

Another safety feature to consider is a backup power source. In the event of a power outage or failure, a backup power source ensures that the lifter can still hold onto the glass until it can be safely lowered to the ground. This feature is particularly important when working at heights or in areas where power interruptions are common.

Furthermore, it is essential to evaluate the lifter’s control system. A user-friendly control system allows for easy operation and reduces the risk of operator error. Look for a lifter with intuitive controls and clear indicators that provide feedback on the lifter’s status and operation.

Lastly, consider the maintenance requirements of the vacuum glass lifter. Regular maintenance is necessary to ensure the lifter’s continued performance and safety. Look for a lifter that is easy to clean and maintain, with readily available spare parts and a reliable customer support system.

In conclusion, when choosing a vacuum glass lifter for your business, it is important to evaluate both its performance and safety features. Consider factors such as lifting capacity, suction power, safety systems, control system, and maintenance requirements. By carefully assessing these aspects, you can select a lifter that meets your business’s specific needs and ensures the safe and efficient handling of glass materials.