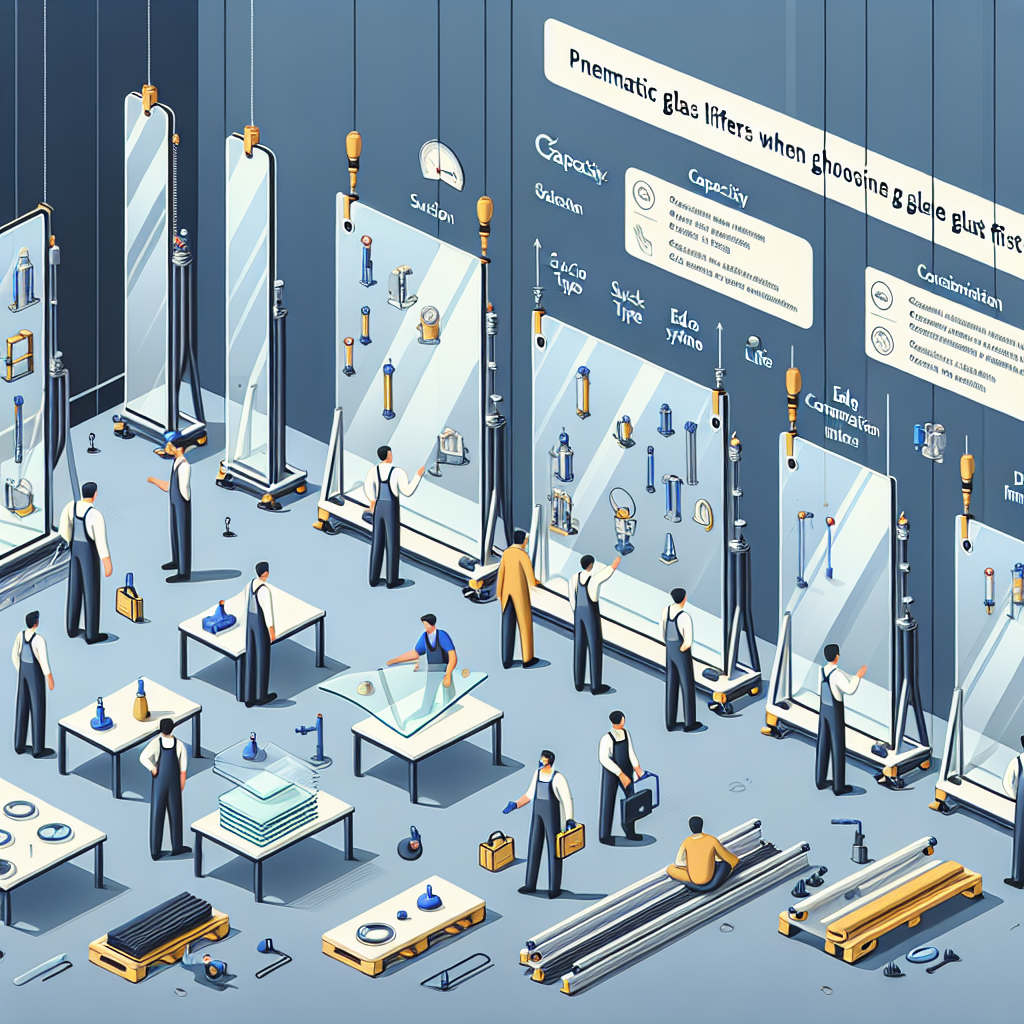

Key Factors to Consider When Selecting a Pneumatic Glass Lifter

When it comes to selecting a pneumatic glass lifter for your business, there are several key factors that you need to consider. This article will guide you through the process of choosing the right pneumatic glass lifter, ensuring that you make an informed decision that meets the specific needs of your business.

The first factor to consider is the lifting capacity of the glass lifter. It is important to determine the maximum weight that the lifter will need to handle in order to ensure that it is capable of lifting the glass panels that you work with. You should also consider the size and dimensions of the glass panels, as this will affect the lifter’s ability to securely grip and lift them.

Another important factor to consider is the reach of the glass lifter. You need to determine the maximum height that the lifter will need to reach in order to safely install or remove glass panels. This will depend on the specific requirements of your business, such as the height of the buildings that you work on. It is also worth considering whether you need a lifter with a telescopic arm, which can provide additional reach when needed.

The type of glass lifter is also an important consideration. There are various types available, including suction cup lifters and vacuum lifters. Suction cup lifters are typically used for smaller glass panels, while vacuum lifters are better suited for larger and heavier panels. You should carefully assess your needs and the types of glass panels that you work with in order to determine the most suitable type of lifter for your business.

In addition to the lifting capacity, reach, and type of lifter, you should also consider the safety features of the glass lifter. Safety should always be a top priority, especially when working with heavy and fragile materials such as glass. Look for lifters that have features such as automatic suction loss detection and alarms, as well as safety interlocks to prevent accidental release of the glass panels.

Furthermore, it is important to consider the ease of use and maneuverability of the glass lifter. Look for lifters that have user-friendly controls and ergonomic designs, as these will make it easier for your employees to operate the lifter safely and efficiently. Consider the weight and size of the lifter, as well as any additional features such as adjustable handles or wheels for easy transportation.

Lastly, you should also consider the maintenance and support options for the glass lifter. Look for lifters that are easy to maintain and service, with readily available spare parts. It is also worth considering whether the manufacturer offers training and technical support for the lifter, as this can be invaluable in ensuring that your employees are able to use the lifter effectively and safely.

In conclusion, choosing the right pneumatic glass lifter for your business requires careful consideration of several key factors. By assessing the lifting capacity, reach, type, safety features, ease of use, and maintenance options, you can make an informed decision that meets the specific needs of your business. Investing in the right glass lifter will not only improve the efficiency and safety of your operations but also contribute to the overall success of your business.

Understanding the Different Types of Pneumatic Glass Lifters and Their Applications

Pneumatic glass lifters are essential tools for businesses that deal with glass installation or transportation. These devices use compressed air to create a vacuum, allowing them to lift and move heavy glass panels with ease. However, with so many different types of pneumatic glass lifters available on the market, it can be challenging to choose the right one for your specific needs. In this section, we will explore the various types of pneumatic glass lifters and their applications, helping you make an informed decision.

One of the most common types of pneumatic glass lifters is the single-cup lifter. As the name suggests, this lifter features a single suction cup that attaches to the glass surface. Single-cup lifters are ideal for smaller glass panels or when working in tight spaces. They are lightweight and easy to maneuver, making them suitable for tasks that require precision and control.

For larger glass panels or heavier loads, a multiple-cup lifter may be more appropriate. These lifters have multiple suction cups arranged in a pattern, allowing for a more even distribution of weight. This design provides greater stability and lifting capacity, making it suitable for larger glass panels or when working with thicker glass.

Another type of pneumatic glass lifter is the rotating lifter. These lifters feature a rotating mechanism that allows the glass panel to be rotated while being lifted. This feature is particularly useful when installing glass in hard-to-reach areas or when precise positioning is required. Rotating lifters are commonly used in architectural projects where glass needs to be installed at various angles or orientations.

In some cases, businesses may require a pneumatic glass lifter that can handle both vertical and horizontal lifting. For these situations, a versatile lifter with adjustable suction cups may be the best choice. These lifters allow for easy adjustment of the cup positions, enabling them to lift glass panels in both orientations. This versatility is especially beneficial for businesses that handle a wide range of glass installation projects.

When choosing a pneumatic glass lifter, it is also essential to consider the lifting capacity and safety features. The lifting capacity refers to the maximum weight that the lifter can handle. It is crucial to select a lifter that can handle the weight of the glass panels you typically work with. Additionally, look for lifters with safety features such as audible alarms or visual indicators that alert the operator if the vacuum seal is compromised.

Lastly, consider the power source of the pneumatic glass lifter. Some lifters are powered by an external air compressor, while others have an integrated air pump. The choice between these two options depends on the availability of compressed air in your workspace and the portability requirements of your business.

In conclusion, understanding the different types of pneumatic glass lifters and their applications is crucial when choosing the right one for your business. Consider factors such as the size and weight of the glass panels you work with, the need for rotation or versatility, and the lifting capacity and safety features. By carefully evaluating these factors, you can select a pneumatic glass lifter that meets your specific needs and enhances the efficiency and safety of your glass installation or transportation processes.

Tips for Evaluating the Performance and Safety Features of Pneumatic Glass Lifters

Pneumatic glass lifters are essential tools for businesses that deal with glass installation or handling. These devices are designed to lift and transport heavy glass panels safely and efficiently. However, with so many options available in the market, choosing the right pneumatic glass lifter for your business can be a daunting task. To help you make an informed decision, this article will provide you with tips for evaluating the performance and safety features of pneumatic glass lifters.

First and foremost, it is crucial to consider the lifting capacity of the glass lifter. The lifting capacity refers to the maximum weight that the lifter can handle. It is essential to choose a lifter that can handle the weight of the glass panels you typically work with. Overloading a glass lifter can lead to accidents and damage to the equipment or the glass itself. Therefore, it is advisable to choose a lifter with a higher lifting capacity than your heaviest glass panel to ensure safety and efficiency.

Another important factor to consider is the lifting height of the glass lifter. The lifting height refers to the maximum height to which the lifter can raise the glass panel. It is crucial to choose a lifter that can reach the desired height for your specific application. Whether you need to lift glass panels to a certain floor or install them at a specific height, selecting a lifter with an appropriate lifting height is essential.

In addition to lifting capacity and height, evaluating the maneuverability of the glass lifter is also crucial. A pneumatic glass lifter should be easy to maneuver and operate, allowing your workers to handle glass panels with precision and control. Look for lifters with features such as adjustable suction cups, swivel capabilities, and smooth movement mechanisms. These features will enhance the maneuverability of the lifter and make it easier for your workers to position and transport glass panels.

Safety features should also be a top priority when evaluating pneumatic glass lifters. Look for lifters that have safety mechanisms in place to prevent accidents and protect both the workers and the glass panels. Features such as automatic suction loss detection, audible alarms, and emergency stop buttons are essential for ensuring the safety of your workers and preventing damage to the glass.

Furthermore, it is advisable to choose a glass lifter that is easy to maintain and service. Regular maintenance is crucial for keeping the lifter in optimal condition and prolonging its lifespan. Look for lifters that have easily accessible components and come with clear maintenance instructions. Additionally, consider the availability of spare parts and the reputation of the manufacturer for providing reliable customer support.

Lastly, it is always a good idea to read reviews and seek recommendations from other businesses in your industry. Hearing about the experiences of others who have used a particular glass lifter can provide valuable insights and help you make an informed decision.

In conclusion, choosing the right pneumatic glass lifter for your business requires careful evaluation of its performance and safety features. Consider factors such as lifting capacity, lifting height, maneuverability, safety features, ease of maintenance, and customer reviews. By taking these factors into account, you can select a glass lifter that meets your specific needs, enhances productivity, and ensures the safety of your workers and glass panels.