Key Factors to Consider When Selecting a Pneumatic Glass Lifter

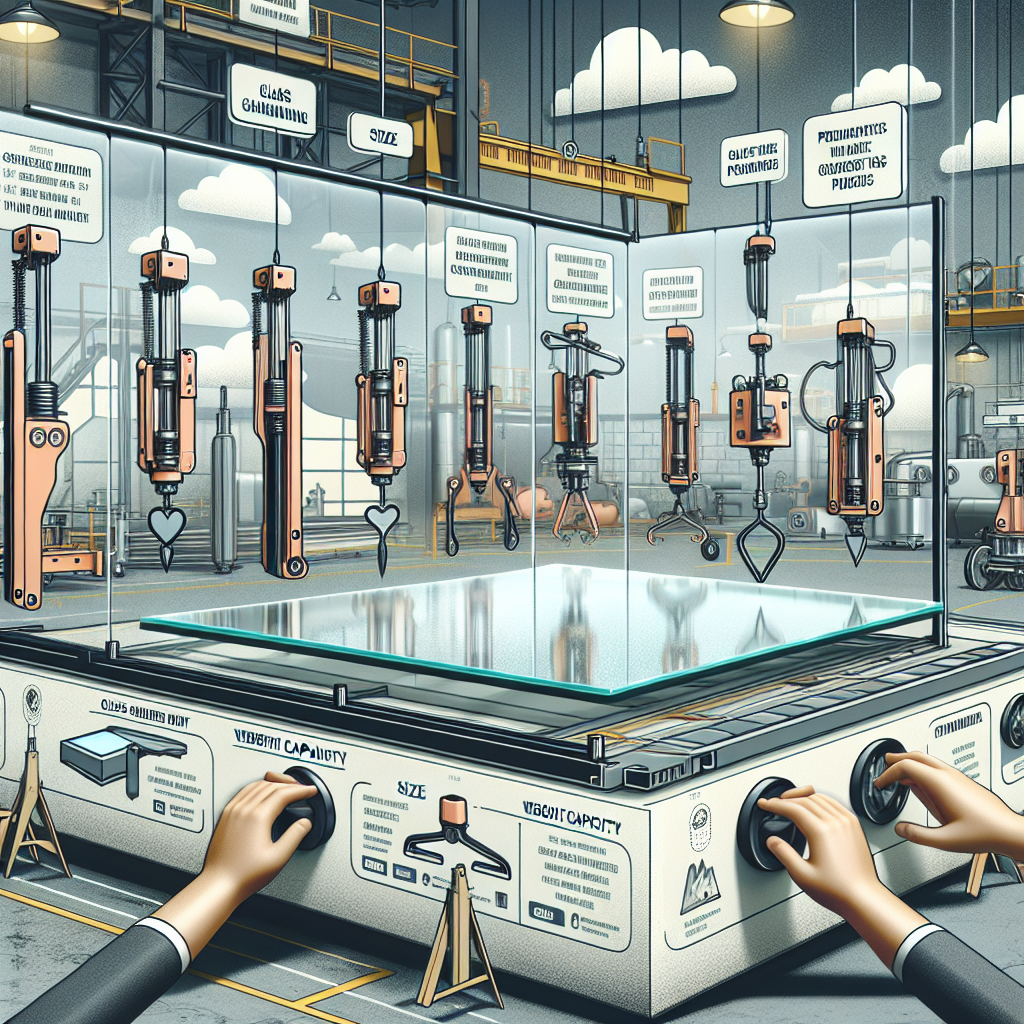

When it comes to selecting a pneumatic glass lifter for your business, there are several key factors that you need to consider. This article will guide you through the process of choosing the right pneumatic glass lifter, ensuring that you make an informed decision that meets the specific needs of your business.

The first factor to consider is the lifting capacity of the glass lifter. It is important to determine the maximum weight that the lifter will need to handle in order to ensure that it is capable of lifting the glass panels that you work with. You should also consider the size and dimensions of the glass panels, as this will affect the lifter’s ability to securely grip and lift them.

Another important factor to consider is the reach of the glass lifter. You need to determine the maximum height that the lifter will need to reach in order to safely install or remove glass panels. This will depend on the specific requirements of your business, such as the height of the buildings that you work on. It is also worth considering whether you need a lifter with a telescopic arm, which can provide additional reach when needed.

The type of glass lifter is also an important consideration. There are various types available, including suction cup lifters and vacuum lifters. Suction cup lifters are typically used for smaller glass panels, while vacuum lifters are better suited for larger and heavier panels. You should carefully assess your needs and the types of glass panels that you work with in order to determine the most suitable type of lifter for your business.

In addition to the lifting capacity, reach, and type of lifter, you should also consider the safety features of the glass lifter. Safety should always be a top priority, especially when working with heavy and fragile materials such as glass. Look for lifters that have features such as automatic suction loss detection and alarms, as well as safety interlocks to prevent accidental release of the glass panels.

Furthermore, it is important to consider the ease of use and maneuverability of the glass lifter. Look for lifters that are user-friendly and have intuitive controls. Consider the weight and size of the lifter, as well as its maneuverability in tight spaces or on uneven surfaces. This will ensure that your employees can operate the lifter efficiently and safely.

Lastly, you should also consider the maintenance and servicing requirements of the glass lifter. Look for lifters that are easy to maintain and have readily available spare parts. It is also worth considering whether the manufacturer offers training and support for the lifter, as this can be beneficial for your employees.

In conclusion, choosing the right pneumatic glass lifter for your business requires careful consideration of several key factors. These include the lifting capacity, reach, type, safety features, ease of use, and maintenance requirements of the lifter. By taking the time to assess your specific needs and thoroughly research the available options, you can ensure that you select a glass lifter that meets the requirements of your business and enhances your productivity and safety.

Understanding the Different Types of Pneumatic Glass Lifters and Their Applications

Pneumatic glass lifters are essential tools for businesses that deal with glass installation or transportation. These devices use compressed air to create a vacuum, allowing them to lift and move heavy glass panels with ease. However, with so many different types of pneumatic glass lifters available on the market, it can be challenging to choose the right one for your specific needs. In this section, we will discuss the various types of pneumatic glass lifters and their applications, helping you make an informed decision.

One of the most common types of pneumatic glass lifters is the single-cup lifter. As the name suggests, this lifter features a single suction cup that attaches to the glass surface. Single-cup lifters are ideal for smaller glass panels or when working in tight spaces. They are lightweight and easy to maneuver, making them suitable for tasks that require precision and control.

For larger glass panels or heavier loads, a multiple-cup lifter may be more appropriate. These lifters have multiple suction cups arranged in a pattern, allowing for a more even distribution of weight. This design provides greater stability and lifting capacity, making it suitable for lifting larger glass panels or other heavy objects.

Another type of pneumatic glass lifter is the rotating lifter. These lifters feature a rotating mechanism that allows the glass panel to be rotated while being lifted. This feature is particularly useful when installing glass in hard-to-reach areas or when precise positioning is required. Rotating lifters are commonly used in construction projects or when installing glass in high-rise buildings.

In addition to the different types of lifters, it is also essential to consider the lifting capacity and safety features of the pneumatic glass lifter. The lifting capacity refers to the maximum weight that the lifter can safely handle. It is crucial to choose a lifter that can handle the weight of the glass panels you will be working with to ensure safe and efficient operation.

Safety features are another crucial aspect to consider when choosing a pneumatic glass lifter. Look for lifters that have features such as automatic vacuum monitoring, which alerts the operator if the vacuum seal is compromised. This feature helps prevent accidents and ensures the safety of both the operator and the glass panels being lifted.

Furthermore, it is essential to consider the power source of the pneumatic glass lifter. Some lifters are powered by an external air compressor, while others have an integrated air pump. The choice between these two options depends on the availability of a compressed air source and the portability requirements of your business.

Lastly, consider the overall quality and durability of the pneumatic glass lifter. Look for lifters made from high-quality materials that can withstand the demands of your business. It is also advisable to choose lifters from reputable manufacturers that offer warranties and after-sales support.

In conclusion, choosing the right pneumatic glass lifter for your business requires careful consideration of the different types available and their specific applications. Consider factors such as lifting capacity, safety features, power source, and overall quality to ensure that you select a lifter that meets your needs and provides reliable performance. By making an informed decision, you can enhance the efficiency and safety of your glass installation or transportation processes.

Tips for Evaluating the Performance and Safety Features of Pneumatic Glass Lifters

Pneumatic glass lifters are essential tools for businesses that deal with glass installation or handling. These devices provide a safe and efficient way to lift and transport heavy glass panels, reducing the risk of accidents and injuries. However, with so many options available in the market, choosing the right pneumatic glass lifter for your business can be a daunting task. In this article, we will provide you with some tips for evaluating the performance and safety features of pneumatic glass lifters, helping you make an informed decision.

First and foremost, it is crucial to consider the lifting capacity of the glass lifter. Different models have different weight capacities, so you need to ensure that the lifter you choose can handle the size and weight of the glass panels you typically work with. It is always better to choose a lifter with a higher lifting capacity than you currently need, as it allows for future growth and flexibility.

Another important factor to consider is the lifting mechanism of the glass lifter. Pneumatic glass lifters use compressed air to create a vacuum seal, allowing them to lift and hold glass panels securely. However, the quality and efficiency of the lifting mechanism can vary between models. Look for lifters that have a reliable and powerful vacuum pump, as this will ensure a strong and secure grip on the glass.

In addition to the lifting mechanism, you should also evaluate the safety features of the glass lifter. Safety should always be a top priority, especially when working with heavy and fragile materials like glass. Look for lifters that have features such as automatic safety locks, which prevent accidental release of the glass panels. Some models also come with audible and visual alarms to alert operators in case of any issues or malfunctions.

Furthermore, it is essential to consider the maneuverability and ease of use of the glass lifter. Look for models that have swivel casters or wheels, as these allow for easy movement and positioning of the lifter. Additionally, choose lifters that have user-friendly controls and ergonomic handles, as these will make the operation of the lifter more comfortable and efficient.

When evaluating the performance of a glass lifter, it is also important to consider its power source. Pneumatic glass lifters can be powered by either electricity or compressed air. Electric-powered lifters are generally more convenient and easier to use, as they do not require an external air supply. However, they may not be suitable for all environments, especially those with limited access to electricity. Compressed air-powered lifters, on the other hand, are more versatile and can be used in a wider range of settings. Consider your specific needs and the availability of power sources when choosing between electric and pneumatic lifters.

Lastly, do not forget to consider the overall build quality and durability of the glass lifter. Look for models that are made from high-quality materials and have a sturdy construction. A well-built lifter will not only last longer but also provide better performance and safety.

In conclusion, choosing the right pneumatic glass lifter for your business requires careful evaluation of its performance and safety features. Consider factors such as lifting capacity, lifting mechanism, safety features, maneuverability, power source, and build quality. By taking these factors into account, you can ensure that you invest in a glass lifter that meets your business needs and provides a safe and efficient solution for handling glass panels.