Factors to Consider When Selecting a Glass Lifter Sucker

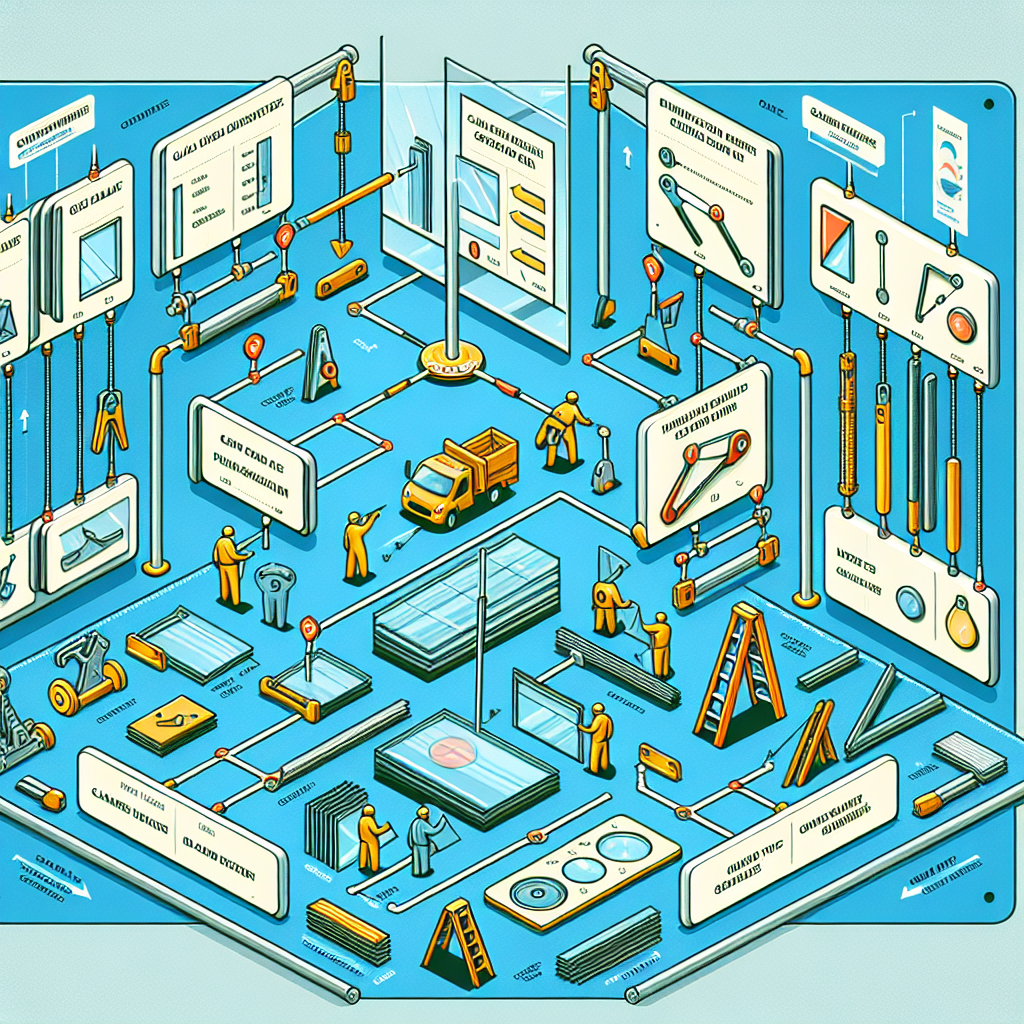

When it comes to working with glass, having the right tools is essential. One tool that is commonly used in the glass industry is a glass lifter sucker. This device is designed to lift and move glass panels safely and efficiently. However, with so many options available on the market, it can be overwhelming to choose the right glass lifter sucker for your project. In this article, we will discuss the factors that you should consider when selecting a glass lifter sucker.

The first factor to consider is the weight capacity of the glass lifter sucker. Different lifters have different weight capacities, so it is important to choose one that can handle the weight of the glass panels you will be working with. It is always better to choose a lifter with a higher weight capacity than you think you will need, as this will ensure that it can handle any unexpected situations that may arise.

Another important factor to consider is the size and shape of the glass panels you will be working with. Glass lifters come in various sizes and shapes, and it is important to choose one that is compatible with the panels you will be lifting. Some lifters are designed specifically for flat glass panels, while others are designed for curved or irregularly shaped panels. Make sure to choose a lifter that is suitable for the type of glass panels you will be working with.

The type of suction cups used in the glass lifter sucker is also an important consideration. Suction cups come in different materials and designs, and choosing the right ones can greatly affect the performance of the lifter. For example, if you will be working with rough or textured glass, it is important to choose suction cups that have a strong grip. On the other hand, if you will be working with delicate or thin glass, it is important to choose suction cups that are gentle and will not damage the glass.

The power source of the glass lifter sucker is another factor to consider. Some lifters are powered by electricity, while others are powered by air or manual operation. The choice of power source depends on your specific needs and preferences. Electric lifters are generally more powerful and can handle heavier loads, but they require access to electricity. Air-powered lifters are more portable and can be used in areas without electricity, but they may not have the same lifting capacity as electric lifters. Manual lifters are the most basic and require physical effort to operate, but they can be a cost-effective option for smaller projects.

Lastly, it is important to consider the safety features of the glass lifter sucker. Working with glass can be dangerous, so it is important to choose a lifter that has safety features such as a locking mechanism or an emergency release valve. These features can prevent accidents and ensure the safety of the operator and the glass panels.

In conclusion, choosing the right glass lifter sucker for your project requires careful consideration of several factors. These include the weight capacity, size and shape compatibility, suction cup type, power source, and safety features. By taking these factors into account, you can ensure that you choose a glass lifter sucker that is suitable for your specific needs and will help you complete your glass projects safely and efficiently.

Different Types of Glass Lifters and Their Applications

Different Types of Glass Lifters and Their Applications

When it comes to working with glass, having the right tools is essential. One such tool that is commonly used in the glass industry is the glass lifter sucker. Glass lifters are designed to provide a secure grip on glass panels, making it easier and safer to transport and install them. However, with so many different types of glass lifters available on the market, it can be overwhelming to choose the right one for your project. In this article, we will discuss the different types of glass lifters and their applications, helping you make an informed decision.

One of the most common types of glass lifters is the vacuum glass lifter. This type of lifter uses suction cups to create a vacuum seal between the lifter and the glass panel. Vacuum glass lifters are versatile and can be used for a wide range of glass lifting applications, including lifting and moving large glass panels, windows, and doors. They are particularly useful for projects that require lifting heavy or oversized glass panels, as they provide a secure grip and prevent the glass from slipping or falling.

Another type of glass lifter is the manual glass lifter. As the name suggests, manual glass lifters are operated manually, without the need for any external power source. These lifters are typically used for smaller glass panels or in situations where power is not readily available. Manual glass lifters are lightweight and portable, making them ideal for projects that require frequent movement or lifting in tight spaces. They are also a cost-effective option for those on a budget.

For projects that require lifting glass panels in tight or hard-to-reach areas, a compact glass lifter may be the best choice. Compact glass lifters are designed to be small and lightweight, allowing them to fit into narrow spaces and maneuver easily. They are often used in construction projects where space is limited, such as high-rise buildings or renovation projects. Compact glass lifters are also commonly used in the automotive industry for installing windshields and windows.

In addition to these types of glass lifters, there are also specialized lifters available for specific applications. For instance, there are glass lifters designed specifically for curved glass panels. These lifters have a curved shape that matches the contour of the glass, providing a secure grip and preventing any damage to the glass during lifting. Similarly, there are glass lifters designed for lifting glass with textured or uneven surfaces. These lifters have special suction cups or gripping mechanisms that ensure a secure grip on the glass, regardless of its surface texture.

When choosing a glass lifter sucker for your project, it is important to consider the specific requirements of your project, such as the size and weight of the glass panels, the type of surface texture, and the available space for maneuvering. Additionally, it is crucial to ensure that the glass lifter you choose meets all safety standards and regulations. Investing in a high-quality glass lifter will not only make your project easier and more efficient but also ensure the safety of your workers and the integrity of the glass panels.

In conclusion, choosing the right glass lifter sucker for your project is crucial for ensuring the safe and efficient handling of glass panels. By understanding the different types of glass lifters and their applications, you can make an informed decision that meets the specific requirements of your project. Whether you need a vacuum glass lifter, a manual glass lifter, a compact glass lifter, or a specialized lifter, there is a wide range of options available on the market. Take the time to research and choose a glass lifter that is not only suitable for your project but also meets all safety standards and regulations.

Tips for Choosing the Right Glass Lifter Sucker for Your Specific Project

Choosing the right glass lifter sucker for your project is crucial to ensure the safety and efficiency of your work. With so many options available in the market, it can be overwhelming to make the right choice. However, by considering a few key factors, you can easily select the perfect glass lifter sucker for your specific project.

First and foremost, it is important to assess the weight and size of the glass you will be working with. Glass lifters come in various weight capacities, so it is essential to choose one that can handle the weight of your glass panels. Additionally, consider the size of the glass and ensure that the suction cups on the lifter are large enough to securely hold the glass in place. This will prevent any accidents or damage during the lifting process.

Another important factor to consider is the type of surface you will be working on. Different glass lifters are designed for specific surfaces, such as smooth or rough. If you are working on a smooth surface, such as glass or marble, a lifter with suction cups specifically designed for smooth surfaces will provide the best grip. On the other hand, if you are working on a rough surface, such as concrete or wood, opt for a lifter with suction cups that are designed to handle rough surfaces. This will ensure that the lifter adheres securely to the surface, providing stability and safety.

Furthermore, consider the type of glass you will be working with. Some glass lifters are designed for flat glass panels, while others are suitable for curved or irregularly shaped glass. If you are working with curved or irregularly shaped glass, choose a lifter that has adjustable suction cups or specialized attachments to accommodate the shape of the glass. This will ensure a secure grip and prevent any damage to the glass during the lifting process.

In addition to these factors, it is important to consider the overall quality and durability of the glass lifter sucker. Look for lifters that are made from high-quality materials, such as stainless steel or aluminum, as they are more likely to withstand heavy use and provide long-lasting performance. Additionally, check for any safety features, such as a pressure release valve, which allows for easy and controlled release of the suction cups.

Lastly, consider your budget when choosing a glass lifter sucker. While it is important to invest in a high-quality lifter, it is also essential to find one that fits within your budget. Compare prices and features of different lifters to find the best value for your money.

In conclusion, choosing the right glass lifter sucker for your project requires careful consideration of factors such as weight and size of the glass, type of surface, type of glass, overall quality and durability, and budget. By taking these factors into account, you can ensure that you select a lifter that is safe, efficient, and suitable for your specific project. Remember to always prioritize safety and quality when making your decision, as this will ultimately determine the success of your glass lifting endeavors.