Increased Efficiency and Productivity in Glass Handling with Pneumatic Glass Lifters

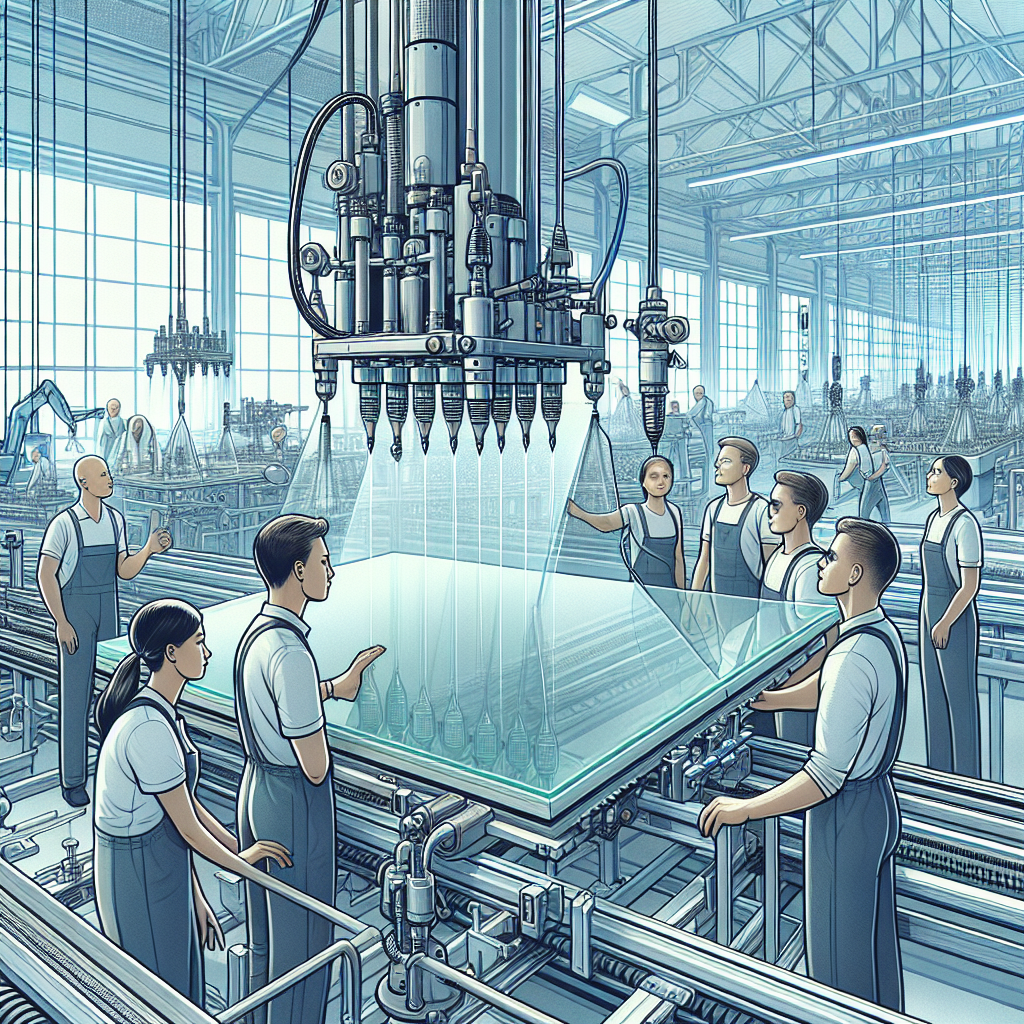

The glass industry has seen significant advancements in recent years, with one of the most notable being the introduction of pneumatic glass lifters. These innovative devices have revolutionized the way glass is handled, offering increased efficiency and productivity in glass handling processes.

Pneumatic glass lifters are designed to lift and transport glass panels with ease. They utilize the power of compressed air to create a vacuum seal between the lifter and the glass surface, allowing for secure and stable lifting. This eliminates the need for manual lifting and reduces the risk of accidents and injuries associated with glass handling.

One of the key benefits of pneumatic glass lifters is their ability to streamline the glass handling process. Traditional methods of glass handling often involve multiple workers and specialized equipment, such as cranes or forklifts. This can be time-consuming and labor-intensive, leading to delays in production and increased costs.

With pneumatic glass lifters, however, the process becomes much simpler and more efficient. A single operator can easily maneuver the lifter and position it precisely where it is needed. This eliminates the need for additional manpower and reduces the time required to complete glass handling tasks. As a result, companies can increase their productivity and meet tight deadlines more effectively.

Furthermore, pneumatic glass lifters offer a high level of versatility. They can be used to handle a wide range of glass sizes and shapes, including curved or irregularly shaped panels. This flexibility allows glass manufacturers to take on a variety of projects without the need for specialized equipment or additional investments.

In addition to increased efficiency, pneumatic glass lifters also contribute to improved safety in the workplace. Glass handling can be a hazardous task, as glass panels are heavy and fragile. Accidents can easily occur if proper precautions are not taken.

Pneumatic glass lifters address these safety concerns by providing a secure and stable lifting solution. The vacuum seal created between the lifter and the glass surface ensures that the panels are held firmly in place during transport. This reduces the risk of glass breakage and minimizes the potential for injuries to workers.

Moreover, pneumatic glass lifters are equipped with safety features such as audible alarms and visual indicators to alert operators of any potential issues. This allows for quick response and prevents accidents from occurring.

In conclusion, pneumatic glass lifters have revolutionized the glass industry by offering increased efficiency and productivity in glass handling processes. These devices streamline the handling process, eliminating the need for manual lifting and reducing the risk of accidents and injuries. They also provide versatility, allowing for the handling of various glass sizes and shapes. Additionally, pneumatic glass lifters contribute to improved safety in the workplace, ensuring that workers can handle glass panels securely and without risk. With these benefits, it is clear that pneumatic glass lifters are a valuable tool for the glass industry, enabling companies to meet the demands of their customers more effectively and efficiently.

Enhancing Safety Measures in the Glass Industry through Pneumatic Glass Lifters

The glass industry has seen significant advancements in recent years, with new technologies and equipment revolutionizing the way glass is handled and transported. One such innovation that has gained popularity is the pneumatic glass lifter. These devices have proven to be a game-changer in the industry, enhancing safety measures and streamlining operations.

Pneumatic glass lifters are designed to lift and transport glass panels with ease and precision. They utilize the power of compressed air to create a vacuum seal, securely gripping the glass and allowing it to be lifted and moved without the need for manual handling. This eliminates the risk of accidents and injuries that are commonly associated with lifting heavy glass panels.

One of the key advantages of pneumatic glass lifters is their ability to handle large and heavy glass panels with minimal effort. In the past, workers had to rely on manual lifting techniques, which often led to strained muscles, back injuries, and even dropped glass panels. With pneumatic glass lifters, these risks are significantly reduced, as the devices do the heavy lifting, allowing workers to focus on other tasks.

Furthermore, pneumatic glass lifters are designed with safety features that further enhance their effectiveness. Many models come equipped with sensors that detect any loss of vacuum pressure, immediately alerting the operator and preventing accidents. Additionally, some lifters are equipped with tilt sensors that detect any tilting or shifting of the glass panel, ensuring that it remains stable and secure during transportation.

Another advantage of pneumatic glass lifters is their versatility. These devices can be easily adjusted to accommodate different sizes and shapes of glass panels, making them suitable for a wide range of applications. Whether it’s lifting large windows for installation in high-rise buildings or handling delicate glass artwork, pneumatic glass lifters can be customized to meet the specific needs of the task at hand.

In addition to enhancing safety measures, pneumatic glass lifters also contribute to increased efficiency and productivity in the glass industry. With the ability to lift and transport glass panels quickly and effortlessly, workers can complete tasks in a fraction of the time it would take using traditional methods. This not only saves time but also allows for more projects to be completed, ultimately boosting profitability for glass manufacturers and installers.

Furthermore, the use of pneumatic glass lifters minimizes the risk of damage to glass panels during handling and transportation. The secure vacuum seal ensures that the glass remains stable and free from scratches or cracks. This is particularly important for high-value glass products, such as architectural glass or custom-made glass pieces, where any damage could result in significant financial losses.

In conclusion, pneumatic glass lifters have revolutionized the glass industry by enhancing safety measures and streamlining operations. These devices eliminate the risks associated with manual lifting, allowing workers to handle large and heavy glass panels with ease. With their versatility and safety features, pneumatic glass lifters have become an indispensable tool in the industry, contributing to increased efficiency and productivity. As the glass industry continues to evolve, it is clear that pneumatic glass lifters will play a crucial role in its future.

Cost Savings and Environmental Benefits of Pneumatic Glass Lifters in the Glass Industry

The glass industry has seen significant advancements in recent years, with new technologies and equipment revolutionizing the way glass is handled and transported. One such innovation that has gained popularity is the pneumatic glass lifter. These devices have proven to be a game-changer for the industry, offering numerous benefits in terms of cost savings and environmental impact.

One of the primary advantages of pneumatic glass lifters is their ability to streamline operations and reduce costs. Traditional methods of handling glass, such as manual lifting or the use of cranes, can be time-consuming and labor-intensive. This not only increases the risk of accidents and injuries but also adds to the overall cost of production. Pneumatic glass lifters, on the other hand, are designed to lift and transport glass with ease, significantly reducing the need for manual labor. This not only saves time but also cuts down on labor costs, making it a cost-effective solution for glass manufacturers.

In addition to cost savings, pneumatic glass lifters also offer significant environmental benefits. The glass industry is known for its high energy consumption and carbon emissions. Traditional methods of glass handling often require the use of heavy machinery or vehicles, which contribute to pollution and greenhouse gas emissions. Pneumatic glass lifters, however, operate on compressed air, eliminating the need for fossil fuels and reducing carbon emissions. This makes them a more sustainable and environmentally friendly option for glass manufacturers.

Furthermore, pneumatic glass lifters are designed to be highly efficient, minimizing waste and breakage. Glass is a fragile material that requires careful handling to prevent damage. Traditional methods of glass handling, such as manual lifting or the use of cranes, can often result in breakage and waste. Pneumatic glass lifters, with their precise control and gentle grip, minimize the risk of breakage, ensuring that glass products reach their destination intact. This not only reduces waste but also saves money by minimizing the need for replacements or repairs.

Another advantage of pneumatic glass lifters is their versatility. These devices can be easily adjusted to accommodate different sizes and shapes of glass, making them suitable for a wide range of applications. Whether it’s lifting large sheets of glass for architectural purposes or delicate glassware for the hospitality industry, pneumatic glass lifters can handle it all. This versatility not only improves efficiency but also allows glass manufacturers to diversify their product offerings, opening up new opportunities for growth and expansion.

In conclusion, pneumatic glass lifters have emerged as a game-changer in the glass industry, offering significant cost savings and environmental benefits. By streamlining operations, reducing labor costs, and minimizing waste, these devices have revolutionized the way glass is handled and transported. Their use of compressed air instead of fossil fuels also makes them a more sustainable and environmentally friendly option. With their versatility and efficiency, pneumatic glass lifters have become an indispensable tool for glass manufacturers, enabling them to meet the demands of a rapidly evolving industry.