Benefits of Using a Vacuum Glass Lifter for Accident Prevention

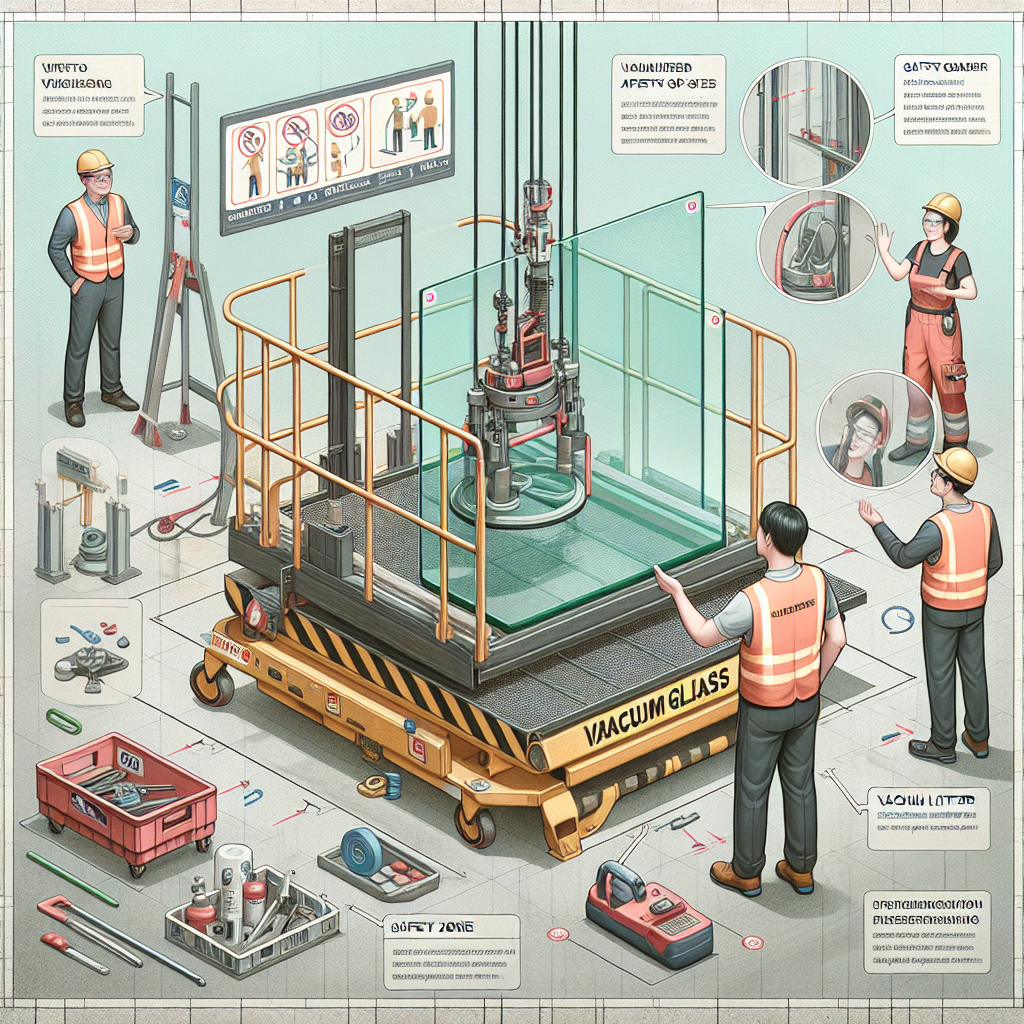

Glass lifting can be a hazardous task, especially when done manually. Accidents can occur, resulting in injuries to workers and damage to the glass. However, with the use of a vacuum glass lifter, these accidents can be prevented, ensuring the safety of workers and the integrity of the glass.

One of the key benefits of using a vacuum glass lifter is that it eliminates the need for manual lifting. Manual lifting of glass can be risky, as it requires workers to exert a significant amount of force and balance the glass carefully. This can lead to strain on the body and increase the chances of accidents occurring. By using a vacuum glass lifter, the glass can be lifted and moved without any physical effort from the workers. This reduces the risk of strain and injuries, making the task much safer.

Another advantage of using a vacuum glass lifter is that it provides a secure grip on the glass. Glass is a fragile material that can easily break or shatter if mishandled. When lifting glass manually, there is always a risk of the glass slipping or falling, causing injuries and damage. However, a vacuum glass lifter uses suction cups to create a strong grip on the glass, ensuring that it remains securely in place during lifting and movement. This significantly reduces the chances of accidents occurring and protects the glass from any potential damage.

Furthermore, a vacuum glass lifter allows for precise and controlled movement of the glass. When working with large or heavy glass panels, it can be challenging to maneuver them accurately. This can lead to accidental collisions with other objects or surfaces, resulting in damage to the glass and potential injuries. However, a vacuum glass lifter is equipped with controls that allow for precise positioning and movement of the glass. This ensures that the glass can be maneuvered safely and accurately, reducing the risk of accidents and damage.

In addition to preventing accidents during lifting and movement, a vacuum glass lifter also helps to prevent accidents during installation. Installing glass panels can be a complex and delicate process, requiring careful alignment and placement. Without the proper equipment, this task can be challenging and dangerous. However, a vacuum glass lifter provides the necessary support and stability to ensure that the glass is installed correctly and securely. This eliminates the risk of the glass falling or shifting during installation, preventing accidents and ensuring the longevity of the glass.

In conclusion, a vacuum glass lifter is a valuable tool for preventing accidents when working with glass. By eliminating the need for manual lifting, providing a secure grip, allowing for precise movement, and ensuring safe installation, a vacuum glass lifter significantly reduces the risk of injuries and damage. Whether it is for lifting and moving glass panels or installing them, using a vacuum glass lifter is a wise investment that prioritizes the safety of workers and the protection of glass.

How Vacuum Glass Lifters Enhance Workplace Safety

How a Vacuum Glass Lifter Can Help Prevent Accidents

In any workplace, safety should always be a top priority. Accidents can happen at any time, and it is crucial to take proactive measures to prevent them. One area where accidents can occur is in the handling of glass. Glass is fragile and can easily break, leading to injuries and damage. However, with the use of a vacuum glass lifter, workplace safety can be greatly enhanced.

A vacuum glass lifter is a device specifically designed to lift and transport glass safely. It works by creating a vacuum seal between the lifter and the glass surface, allowing it to securely hold the glass without the need for manual lifting. This eliminates the risk of glass slipping or falling, which can cause serious injuries.

One of the main advantages of using a vacuum glass lifter is that it reduces the physical strain on workers. Lifting and carrying heavy glass panels manually can put a significant amount of stress on the body, particularly the back and shoulders. Over time, this can lead to chronic pain and musculoskeletal disorders. By using a vacuum glass lifter, the weight of the glass is evenly distributed, reducing the strain on individual workers and minimizing the risk of long-term injuries.

Furthermore, a vacuum glass lifter allows for precise and controlled movement of glass panels. When handling glass manually, there is always a risk of accidental drops or collisions with other objects. These incidents can not only cause injuries but also result in costly damage to the glass itself. With a vacuum glass lifter, workers have better control over the glass, reducing the likelihood of accidents and minimizing the potential for damage.

Another important aspect of workplace safety is efficiency. Accidents and injuries can lead to downtime and increased costs for businesses. By using a vacuum glass lifter, the process of handling glass becomes faster and more efficient. Workers can lift and transport glass panels with ease, reducing the time required for each task. This not only improves productivity but also minimizes the risk of accidents that can occur when rushing or handling glass in a hurry.

Additionally, a vacuum glass lifter can be customized to meet the specific needs of different workplaces. Whether it is a small glass shop or a large construction site, there are vacuum glass lifters available in various sizes and configurations. This ensures that the lifter can be adapted to the specific requirements of each workplace, further enhancing safety and efficiency.

In conclusion, a vacuum glass lifter is a valuable tool for enhancing workplace safety when handling glass. By reducing physical strain, providing better control, improving efficiency, and offering customization options, it helps prevent accidents and injuries. Investing in a vacuum glass lifter not only protects the well-being of workers but also contributes to the overall success and productivity of businesses.

Preventing Accidents with Vacuum Glass Lifters: A Comprehensive Guide

How a Vacuum Glass Lifter Can Help Prevent Accidents

Accidents involving glass can be dangerous and costly. From shattered windows to broken mirrors, the potential for injury and property damage is significant. That’s why it’s crucial to have the right tools and equipment to handle glass safely. One such tool that can greatly reduce the risk of accidents is a vacuum glass lifter.

A vacuum glass lifter is a device specifically designed to lift and move glass panels with ease and precision. It works by creating a vacuum seal between the lifter and the glass surface, allowing for a secure grip. This eliminates the need for manual lifting and reduces the chances of dropping or mishandling the glass.

One of the main advantages of using a vacuum glass lifter is its ability to distribute the weight of the glass evenly. This is particularly important when dealing with large and heavy glass panels. By evenly distributing the weight, the lifter minimizes the strain on the operator’s body, reducing the risk of back injuries and muscle strains.

Furthermore, a vacuum glass lifter provides a secure grip on the glass, preventing it from slipping or sliding during transportation. This is especially crucial when working at heights or in tight spaces where a dropped glass panel could cause significant damage or injury. The vacuum seal ensures that the glass remains firmly in place, giving the operator peace of mind and confidence in their ability to handle the glass safely.

In addition to preventing accidents during transportation, a vacuum glass lifter also reduces the risk of accidents during installation. Installing glass panels can be a delicate and challenging task, requiring precision and careful handling. A vacuum glass lifter simplifies this process by providing a stable and controlled grip on the glass, allowing for accurate placement and alignment.

Moreover, a vacuum glass lifter can be equipped with various attachments and accessories to further enhance its safety features. For instance, some lifters come with adjustable suction cups that can accommodate different sizes and shapes of glass. This ensures a secure grip regardless of the glass panel’s dimensions, reducing the risk of accidents caused by improper lifting techniques.

Additionally, some vacuum glass lifters are equipped with safety alarms and indicators. These features alert the operator if the vacuum seal is compromised or if the lifter’s battery is running low. By providing real-time feedback, these alarms help prevent accidents by ensuring that the lifter is in optimal working condition before lifting and moving glass panels.

It’s worth noting that while a vacuum glass lifter can greatly reduce the risk of accidents, proper training and adherence to safety protocols are still essential. Operators should be trained on how to use the lifter correctly, including how to inspect and maintain it regularly. They should also be aware of the weight limits and other specifications of the lifter to avoid overloading or using it inappropriately.

In conclusion, a vacuum glass lifter is a valuable tool for preventing accidents when handling and installing glass panels. Its ability to distribute weight evenly, provide a secure grip, and offer additional safety features makes it an indispensable asset in any glass-related industry. By investing in a vacuum glass lifter and ensuring proper training, businesses can significantly reduce the risk of accidents, protecting both their employees and their valuable glass products.