Benefits of Using Pneumatic Glass Lifters in Construction Projects

Benefits of Using Pneumatic Glass Lifters in Construction Projects

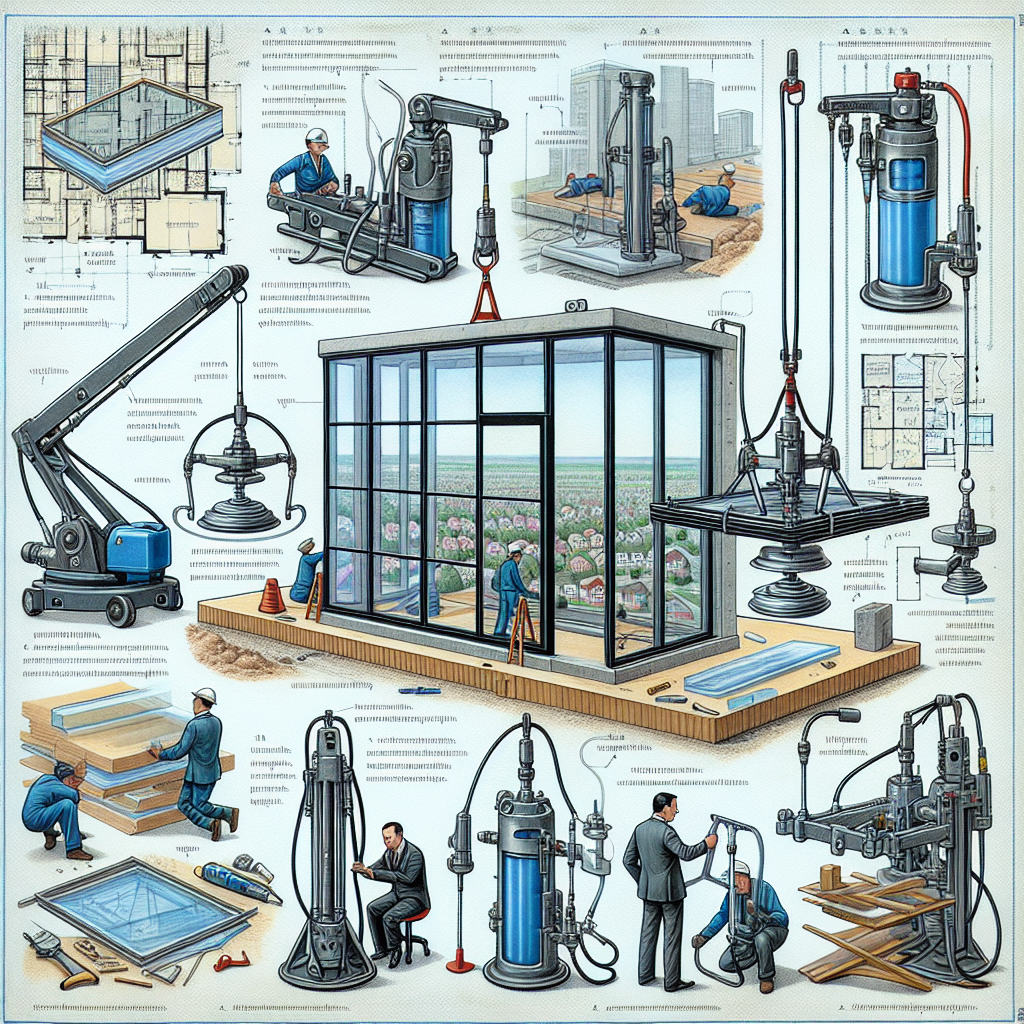

Pneumatic glass lifters have become an essential tool in the construction industry due to their numerous benefits. These lifters are designed to safely and efficiently handle glass panels, making them an invaluable asset for any construction project involving glass installation. In this section, we will explore the various advantages of using pneumatic glass lifters in construction projects.

One of the primary benefits of using pneumatic glass lifters is their ability to enhance worker safety. Glass panels are heavy and fragile, making them challenging to handle manually. By using a pneumatic glass lifter, workers can avoid the risk of injury that comes with lifting and moving heavy glass panels. The lifter’s suction cups securely grip the glass, ensuring a stable and controlled lift, reducing the chances of accidents or damage.

Moreover, pneumatic glass lifters are designed to distribute the weight of the glass evenly, minimizing the strain on workers’ bodies. This feature is particularly crucial when dealing with large and heavy glass panels that would otherwise require multiple workers to lift. By reducing the physical strain on workers, pneumatic glass lifters contribute to a safer and healthier work environment.

Another significant advantage of using pneumatic glass lifters is their efficiency in handling glass panels. These lifters are equipped with powerful vacuum systems that create a strong suction force, allowing for quick and secure lifting and moving of glass panels. This efficiency translates into time savings, as workers can complete glass installation tasks more rapidly compared to manual handling methods. Additionally, the precise control offered by pneumatic glass lifters ensures accurate positioning of glass panels, resulting in a more precise and professional installation.

Furthermore, pneumatic glass lifters are versatile tools that can be used in various construction projects. Whether it is a small-scale residential project or a large commercial building, these lifters can handle glass panels of different sizes and weights. This versatility makes them a cost-effective investment for construction companies, as they can be used across multiple projects without the need for additional equipment.

In addition to their versatility, pneumatic glass lifters are also highly maneuverable. They are designed to be easily transported and operated in tight spaces, such as narrow hallways or confined construction sites. This maneuverability allows for greater flexibility in glass installation, enabling workers to navigate challenging environments with ease.

Lastly, pneumatic glass lifters contribute to a higher quality of workmanship. The precise control and stability provided by these lifters ensure that glass panels are installed accurately and securely. This not only enhances the aesthetic appeal of the finished project but also improves the overall durability and longevity of the glass installation.

In conclusion, the benefits of using pneumatic glass lifters in construction projects are numerous. From enhancing worker safety and efficiency to providing versatility and maneuverability, these lifters have revolutionized the glass installation process. By investing in pneumatic glass lifters, construction companies can improve their productivity, reduce the risk of accidents, and achieve higher quality workmanship.

How to Choose the Right Pneumatic Glass Lifter for Your Needs

Pneumatic glass lifters are an essential tool for anyone working in the glass industry. These devices use compressed air to lift and transport glass panels, making the process safer and more efficient. However, with so many options available on the market, it can be challenging to choose the right pneumatic glass lifter for your specific needs. In this article, we will provide a detailed guide to help you make an informed decision.

When selecting a pneumatic glass lifter, the first thing you need to consider is the weight capacity. Glass panels come in various sizes and thicknesses, so it is crucial to choose a lifter that can handle the weight of the glass you will be working with. It is recommended to choose a lifter with a higher weight capacity than you anticipate needing to ensure it can handle any future projects.

Another important factor to consider is the size and shape of the glass lifter. Some lifters are designed for vertical lifting, while others are more versatile and can handle both vertical and horizontal lifting. If you work with different types of glass panels, it is advisable to choose a lifter that offers both options for maximum flexibility.

The suction cups on the glass lifter are also a crucial consideration. They come in various sizes and shapes, and the right choice depends on the type of glass you will be working with. For example, if you frequently work with curved or irregularly shaped glass panels, you will need suction cups that can conform to these shapes for a secure grip.

Additionally, it is essential to consider the power source of the pneumatic glass lifter. Some models are powered by an onboard air compressor, while others require an external air supply. If you work in a location where a reliable air supply is not readily available, it may be more convenient to choose a lifter with an onboard air compressor.

Furthermore, the control system of the glass lifter is an important aspect to consider. Some lifters have manual controls, while others offer more advanced features such as remote control or programmable settings. The choice depends on your personal preference and the level of control you require for your specific projects.

Lastly, it is crucial to consider the safety features of the pneumatic glass lifter. Look for lifters that have features such as audible alarms, visual indicators, and automatic release valves to ensure safe operation. Additionally, check if the lifter complies with relevant safety standards and regulations to guarantee its reliability and performance.

In conclusion, choosing the right pneumatic glass lifter for your needs requires careful consideration of several factors. These include weight capacity, size and shape, suction cups, power source, control system, and safety features. By taking the time to evaluate these aspects, you can ensure that you select a lifter that meets your requirements and enhances your productivity and safety when working with glass panels.

Common Applications and Industries that Utilize Pneumatic Glass Lifters

Common Applications and Industries that Utilize Pneumatic Glass Lifters

Pneumatic glass lifters are versatile and efficient tools that have found their place in various industries. These lifters are specifically designed to handle glass panels, making them an essential piece of equipment for businesses involved in glass installation, manufacturing, and transportation. In this section, we will explore some of the common applications and industries that rely on pneumatic glass lifters.

One of the primary industries that extensively uses pneumatic glass lifters is the construction industry. Glass is a popular material in modern architecture, and its use in buildings has become increasingly prevalent. From skyscrapers to residential homes, glass panels are used to create stunning facades and provide natural light. However, handling and installing these large and fragile glass panels can be a challenging task. This is where pneumatic glass lifters come into play. With their ability to securely grip and lift glass panels, these lifters make the installation process safer and more efficient.

Another industry that heavily relies on pneumatic glass lifters is the automotive industry. Car manufacturers often use large glass panels for windshields and windows. These panels need to be handled with care to avoid any damage during the manufacturing process. Pneumatic glass lifters provide a reliable solution for lifting and moving these heavy glass panels, ensuring that they are installed correctly without any scratches or cracks.

The furniture industry is yet another sector that benefits from the use of pneumatic glass lifters. Glass is commonly used in the production of tabletops, shelves, and display cases. These glass components need to be lifted and positioned accurately during the manufacturing process. Pneumatic glass lifters offer a precise and secure grip, allowing furniture manufacturers to handle glass panels with ease and precision.

In addition to these industries, the transportation sector also utilizes pneumatic glass lifters. Glass manufacturers often need to transport their products to various locations, such as construction sites or retail stores. Pneumatic glass lifters enable the safe and efficient loading and unloading of glass panels onto trucks or other transportation vehicles. This not only reduces the risk of damage during transit but also saves time and labor costs.

Moreover, the use of pneumatic glass lifters extends beyond industries. These lifters are also commonly employed in residential settings for tasks such as window replacement or installation. Homeowners or contractors can rely on pneumatic glass lifters to safely handle and position glass panels, eliminating the need for multiple individuals and reducing the risk of accidents or injuries.

In conclusion, pneumatic glass lifters have become indispensable tools in various industries and applications. From construction and automotive to furniture manufacturing and transportation, these lifters offer a safe and efficient solution for handling glass panels. Their ability to securely grip and lift heavy and fragile glass makes them an invaluable asset for businesses and individuals alike. Whether it is installing glass facades on skyscrapers or replacing a window at home, pneumatic glass lifters provide the necessary support to ensure the job is done accurately and safely.