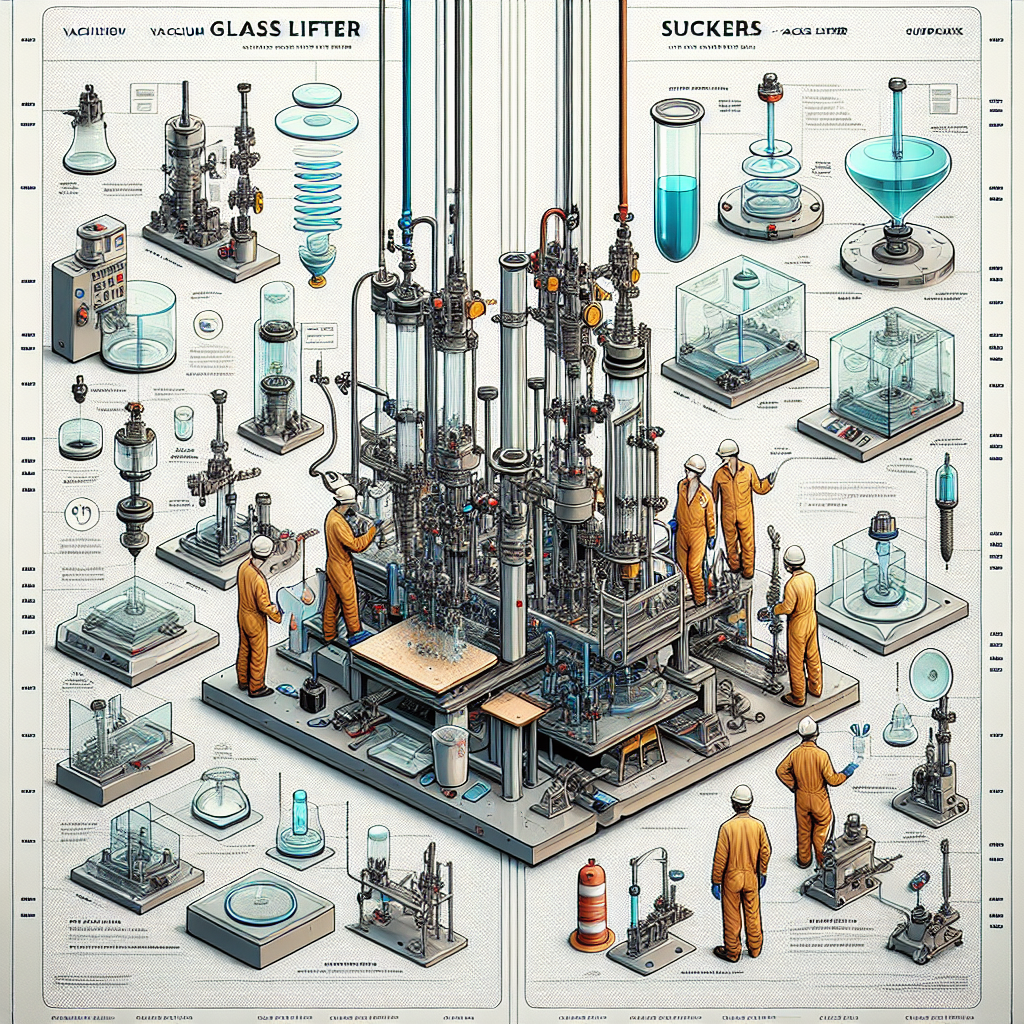

Benefits of Vacuum Glass Lifters in Industrial Applications

Vacuum glass lifters and suckers are both commonly used in industrial applications for handling glass and other smooth, non-porous materials. While they serve the same purpose, there are distinct differences between the two that make vacuum glass lifters a more beneficial choice in many cases.

One of the key benefits of vacuum glass lifters is their ability to handle heavy loads with ease. These lifters are designed to distribute the weight of the load evenly, reducing the risk of damage or breakage. This is particularly important when working with fragile materials such as glass, where even a small amount of pressure can cause cracks or shattering. Vacuum glass lifters use a series of suction cups that create a strong, secure grip on the material, allowing for safe and efficient lifting.

Another advantage of vacuum glass lifters is their versatility. These lifters can be easily adjusted to accommodate different sizes and shapes of materials, making them suitable for a wide range of applications. Whether you need to lift large sheets of glass or smaller, irregularly shaped pieces, vacuum glass lifters can be customized to meet your specific needs. This flexibility is especially valuable in industries such as construction and manufacturing, where materials come in various sizes and dimensions.

In addition to their versatility, vacuum glass lifters also offer increased efficiency in handling materials. The suction cups used in these lifters create a tight seal with the material, minimizing the risk of slippage or dropping. This not only ensures the safety of workers but also reduces the likelihood of damage to the material itself. By securely gripping the material, vacuum glass lifters allow for precise positioning and placement, saving time and effort in the handling process.

Furthermore, vacuum glass lifters are designed with ergonomics in mind. These lifters are equipped with adjustable handles and controls, allowing operators to maintain a comfortable and natural posture while operating the equipment. This reduces the risk of strain or injury, promoting a safer working environment. Additionally, vacuum glass lifters often come with features such as remote control operation, further enhancing operator comfort and convenience.

Lastly, vacuum glass lifters are known for their durability and longevity. These lifters are built to withstand the demands of industrial applications, with robust construction and high-quality materials. This ensures that the lifters can withstand heavy use and continue to perform reliably over time. By investing in vacuum glass lifters, businesses can minimize the need for frequent repairs or replacements, saving both time and money in the long run.

In conclusion, vacuum glass lifters offer numerous benefits in industrial applications. Their ability to handle heavy loads, versatility in accommodating different materials, increased efficiency, ergonomic design, and durability make them a superior choice compared to suckers. Whether you are working with glass, metal, or other smooth materials, vacuum glass lifters provide a safe, efficient, and cost-effective solution for your lifting needs.

Advantages of Suckers for Glass Handling in Construction Projects

Advantages of Suckers for Glass Handling in Construction Projects

When it comes to glass handling in construction projects, there are various tools and equipment available in the market. Two popular options are vacuum glass lifters and suckers. In this section, we will explore the advantages of using suckers for glass handling in construction projects.

One of the main advantages of using suckers is their versatility. Suckers can be used for handling glass of different shapes and sizes. Whether you are working with large glass panels or smaller pieces, suckers can easily adapt to the task at hand. This flexibility makes them a valuable tool for construction projects where glass handling requirements can vary.

Another advantage of using suckers is their ease of use. Suckers are designed to be user-friendly, allowing construction workers to handle glass with minimal effort. The suction cups on the suckers create a strong grip on the glass, making it easier to lift and maneuver. This not only saves time but also reduces the risk of accidents or damage to the glass.

Furthermore, suckers offer a high level of control during glass handling. The suction cups can be adjusted to provide the desired level of grip, ensuring that the glass is securely held in place. This is particularly important when working with delicate or fragile glass, as it minimizes the risk of breakage. The ability to control the grip also allows for precise positioning of the glass, which is crucial in construction projects where accuracy is paramount.

In addition to their versatility, ease of use, and control, suckers also offer a cost-effective solution for glass handling in construction projects. Compared to vacuum glass lifters, suckers are generally more affordable. This makes them a practical choice for construction companies looking to minimize costs without compromising on quality. Moreover, suckers require minimal maintenance, further reducing the overall expenses associated with glass handling.

Another advantage of using suckers is their portability. Suckers are typically lightweight and compact, making them easy to transport and store. This is particularly beneficial for construction projects that involve multiple sites or require frequent movement of glass. The portability of suckers allows for greater flexibility and efficiency in glass handling, as they can be easily transported to different locations as needed.

Lastly, suckers are known for their durability and longevity. Made from high-quality materials, suckers are designed to withstand the rigors of construction projects. They are built to last, ensuring that they can withstand heavy use and continue to perform effectively over time. This durability makes suckers a reliable investment for construction companies, as they can be used for multiple projects without the need for frequent replacements.

In conclusion, suckers offer several advantages for glass handling in construction projects. Their versatility, ease of use, control, cost-effectiveness, portability, and durability make them a practical choice for construction companies. By opting for suckers, construction workers can handle glass with ease, efficiency, and precision, ultimately contributing to the successful completion of construction projects.

Factors to Consider When Choosing Between Vacuum Glass Lifters and Suckers

When it comes to lifting and handling glass, there are several options available in the market. Two popular choices are vacuum glass lifters and suckers. Both of these tools are designed to make glass handling easier and safer, but they have their own unique features and advantages. In this article, we will compare vacuum glass lifters and suckers based on various factors to help you make an informed decision when choosing between the two.

One of the most important factors to consider is the lifting capacity. Vacuum glass lifters are known for their high lifting capacity, which makes them suitable for handling heavy glass panels. They are equipped with powerful vacuum pumps that create a strong suction force, allowing them to lift and transport glass panels weighing several hundred kilograms. On the other hand, suckers have a lower lifting capacity and are more suitable for handling smaller glass pieces or lighter loads.

Another factor to consider is the versatility of the tool. Vacuum glass lifters come in various configurations and can be customized to meet specific requirements. They can be equipped with different types of suction cups, allowing them to handle glass panels of different shapes and sizes. Some vacuum glass lifters also come with additional features such as rotation and tilt functions, which further enhance their versatility. Suckers, on the other hand, are generally less versatile and are more suitable for simple lifting tasks.

The ease of use is another important factor to consider. Vacuum glass lifters are designed to be user-friendly and require minimal effort to operate. They are equipped with ergonomic handles and controls, making them easy to maneuver. Suckers, on the other hand, require manual effort to create suction and lift the glass. This can be physically demanding, especially when handling heavy or large glass panels.

Safety is a crucial consideration when it comes to glass handling. Vacuum glass lifters are designed with safety features such as audible and visual alarms to indicate any loss of vacuum pressure. They also have a backup system that prevents sudden drops in case of power failure. Suckers, on the other hand, do not have these safety features and rely solely on the operator’s vigilance.

Maintenance and durability are also important factors to consider. Vacuum glass lifters require regular maintenance to ensure optimal performance. This includes checking and replacing worn-out suction cups and seals. Suckers, on the other hand, are generally less durable and may require more frequent replacement.

Cost is another factor that can influence your decision. Vacuum glass lifters are generally more expensive than suckers due to their higher lifting capacity and additional features. However, they offer better performance and versatility, which can justify the higher cost for certain applications.

In conclusion, when choosing between vacuum glass lifters and suckers, it is important to consider factors such as lifting capacity, versatility, ease of use, safety, maintenance, durability, and cost. Vacuum glass lifters are generally more suitable for heavy-duty glass handling tasks, while suckers are more suitable for lighter loads. Ultimately, the choice depends on your specific requirements and budget.