The Benefits of Using Vacuum Glass Lifters for Glass Handling

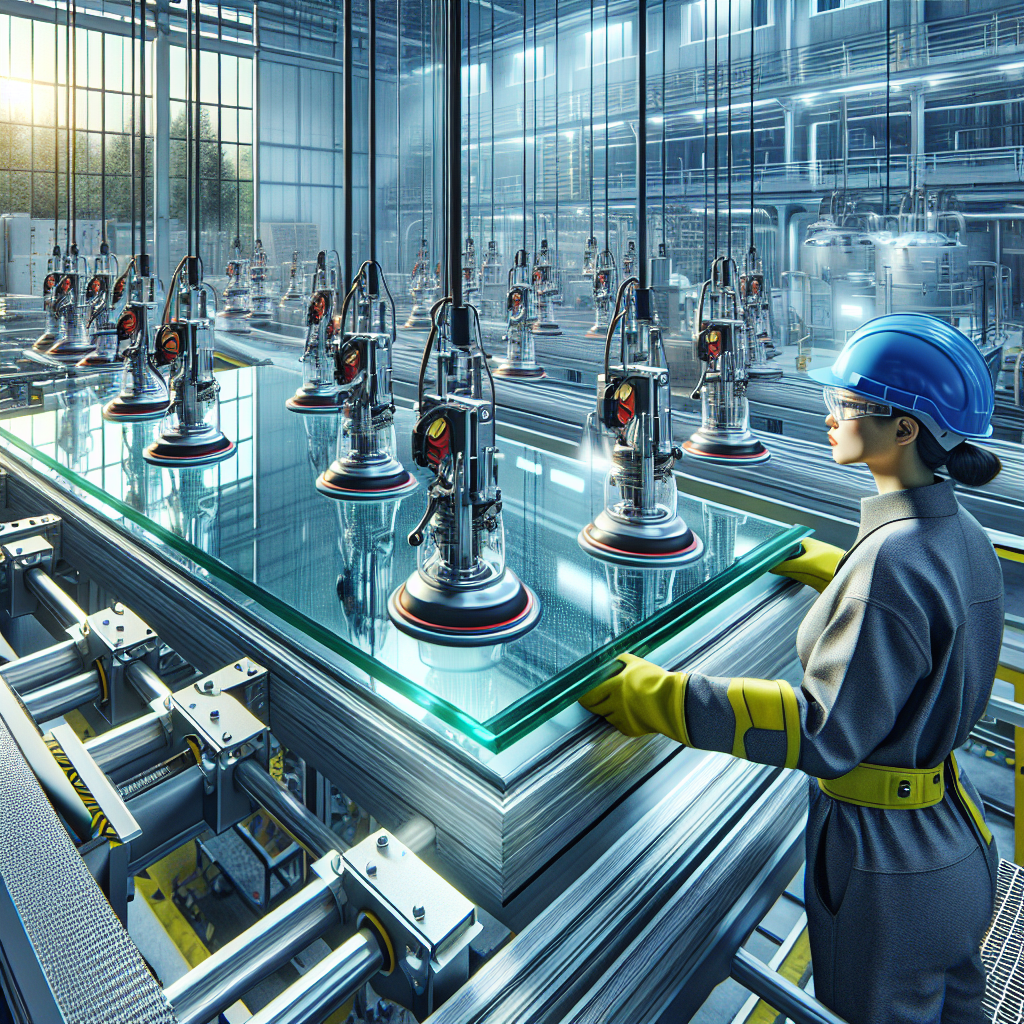

Vacuum glass lifters have revolutionized the way glass is handled in various industries. These innovative devices offer a range of benefits that enhance safety and efficiency in glass handling operations. In this article, we will explore the advantages of using vacuum glass lifters and how they contribute to a safer working environment.

One of the primary benefits of vacuum glass lifters is their ability to reduce the risk of accidents and injuries during glass handling. Traditional methods of lifting and moving glass involve manual labor, which can be physically demanding and hazardous. With vacuum glass lifters, the need for manual lifting is eliminated, significantly reducing the risk of strains, sprains, and other musculoskeletal injuries.

Furthermore, vacuum glass lifters provide a secure grip on the glass, ensuring that it remains stable and intact during transportation. The vacuum suction cups adhere firmly to the glass surface, preventing any slippage or movement that could lead to breakage. This feature is particularly crucial when handling large and heavy glass panels, which can be challenging to maneuver safely without the assistance of a vacuum glass lifter.

In addition to enhancing safety, vacuum glass lifters also improve efficiency in glass handling operations. These devices are designed to lift and transport glass with minimal effort and time. The suction cups can be easily adjusted to accommodate different glass sizes and shapes, allowing for versatile use in various applications. This flexibility eliminates the need for multiple lifting tools, streamlining the glass handling process and reducing downtime.

Moreover, vacuum glass lifters enable precise positioning of glass panels, ensuring accurate installation and alignment. The lifters can be maneuvered with precision, allowing for smooth and controlled movements. This level of control is especially beneficial when working in tight spaces or when dealing with delicate glass pieces that require careful handling.

Another advantage of vacuum glass lifters is their adaptability to different work environments. These devices can be used both indoors and outdoors, making them suitable for a wide range of industries, including construction, manufacturing, and glazing. They are also compatible with various types of glass, such as tempered, laminated, and insulated glass, further expanding their applicability.

Furthermore, vacuum glass lifters are designed with safety features that provide additional protection during glass handling. Many models are equipped with alarms and indicators that alert operators to any potential issues, such as low battery or loss of vacuum pressure. These features help prevent accidents and ensure that the lifter is functioning optimally at all times.

In conclusion, vacuum glass lifters offer numerous benefits that enhance safety and efficiency in glass handling operations. By eliminating manual lifting, providing a secure grip, and enabling precise positioning, these devices significantly reduce the risk of accidents and injuries. They also improve productivity by streamlining the glass handling process and allowing for versatile use in different work environments. With their safety features and adaptability, vacuum glass lifters have become an indispensable tool in the glass industry, contributing to a safer and more efficient working environment.

How Vacuum Glass Lifters Improve Workplace Safety in the Glass Industry

Vacuum glass lifters have become an essential tool in the glass industry, revolutionizing the way glass is handled and improving workplace safety. These innovative devices use the power of suction to securely lift and transport glass panels, reducing the risk of accidents and injuries that were once common in the industry.

One of the main advantages of vacuum glass lifters is their ability to handle heavy and fragile glass panels with ease. In the past, workers had to rely on manual lifting techniques, which often led to strained muscles, back injuries, and even dropped glass panels. With vacuum glass lifters, the risk of dropping glass is significantly reduced, as the suction cups create a strong and reliable grip on the glass surface.

Furthermore, vacuum glass lifters are designed to distribute the weight of the glass evenly, minimizing the strain on individual workers. This is particularly important when dealing with large and heavy glass panels, which can be challenging to lift and maneuver. By reducing the physical effort required to handle glass, vacuum glass lifters help prevent fatigue and reduce the likelihood of accidents caused by tired or overexerted workers.

Another significant advantage of vacuum glass lifters is their ability to enhance precision and control during glass handling. The suction cups can be adjusted to fit different glass sizes and shapes, ensuring a secure grip regardless of the panel’s dimensions. This level of customization allows workers to handle glass panels with greater accuracy, reducing the risk of accidental damage or breakage.

Moreover, vacuum glass lifters are equipped with safety features that further enhance workplace safety. Many models are designed with audible and visual alarms that alert workers if the vacuum seal is compromised or if the lifting capacity is exceeded. These warnings help prevent accidents by providing immediate feedback and allowing workers to take corrective action before any mishaps occur.

In addition to their safety benefits, vacuum glass lifters also improve efficiency and productivity in the glass industry. With traditional lifting methods, it often took multiple workers to handle large glass panels, slowing down the production process. Vacuum glass lifters, on the other hand, allow a single worker to handle glass panels quickly and efficiently, reducing the need for additional manpower and increasing overall productivity.

Furthermore, the speed and ease of glass handling provided by vacuum glass lifters enable workers to complete tasks in a shorter amount of time. This not only saves labor costs but also allows for faster project completion, which is crucial in meeting tight deadlines and satisfying customer demands.

In conclusion, vacuum glass lifters have revolutionized the glass industry by significantly improving workplace safety. These devices provide a secure grip on glass panels, reducing the risk of accidents and injuries caused by dropped or mishandled glass. They also enhance precision and control during glass handling, minimizing the likelihood of accidental damage. With their safety features and efficiency benefits, vacuum glass lifters have become an indispensable tool in the glass industry, ensuring a safer and more productive work environment.

Key Features to Consider When Choosing Vacuum Glass Lifters for Glass Handling

Vacuum glass lifters have become an essential tool in the glass industry, as they provide a safe and efficient way to handle glass. These devices use suction cups to create a vacuum seal on the glass, allowing it to be lifted and moved without the need for manual handling. When choosing a vacuum glass lifter, there are several key features to consider to ensure that it meets your specific needs and enhances safety in glass handling.

One of the most important features to consider is the lifting capacity of the vacuum glass lifter. This refers to the maximum weight that the lifter can safely handle. It is crucial to choose a lifter that can handle the weight of the glass you will be working with. Overloading the lifter can lead to accidents and damage to the glass. Therefore, it is essential to carefully assess the weight of the glass and choose a lifter with an appropriate lifting capacity.

Another important feature to consider is the number and arrangement of suction cups on the lifter. The suction cups are responsible for creating the vacuum seal on the glass, so it is crucial to have enough cups to ensure a secure grip. The arrangement of the cups is also important, as it should be designed to evenly distribute the weight of the glass and prevent any imbalances. A lifter with a well-designed suction cup arrangement will provide a more stable and secure grip on the glass, reducing the risk of accidents.

The type of suction cups used on the lifter is also an important consideration. Different types of suction cups are designed for specific applications and types of glass. For example, there are suction cups specifically designed for curved glass or textured glass. Choosing the right type of suction cups for your specific needs will ensure a secure grip on the glass and prevent any damage or accidents.

In addition to the lifting capacity and suction cup arrangement, it is also important to consider the power source of the vacuum glass lifter. Some lifters are powered by electricity, while others are powered by compressed air. Electric lifters are generally more convenient and easier to use, as they do not require any additional equipment. However, they may not be suitable for all environments, especially those with limited access to electricity. Compressed air-powered lifters, on the other hand, are more versatile and can be used in a wider range of environments. However, they require a separate air compressor, which can add to the overall cost and complexity of the lifter.

Finally, it is important to consider the safety features of the vacuum glass lifter. Look for lifters that have features such as automatic release valves, which allow for quick and safe release of the glass in case of an emergency. Additionally, lifters with built-in safety alarms or indicators can provide an extra layer of protection by alerting the operator if there is a loss of vacuum or any other potential safety issue.

In conclusion, when choosing a vacuum glass lifter for glass handling, it is important to consider several key features. These include the lifting capacity, suction cup arrangement, type of suction cups, power source, and safety features. By carefully considering these features, you can ensure that the lifter meets your specific needs and enhances safety in glass handling.