Benefits of Using Pneumatic Glass Lifters in Glazing Projects

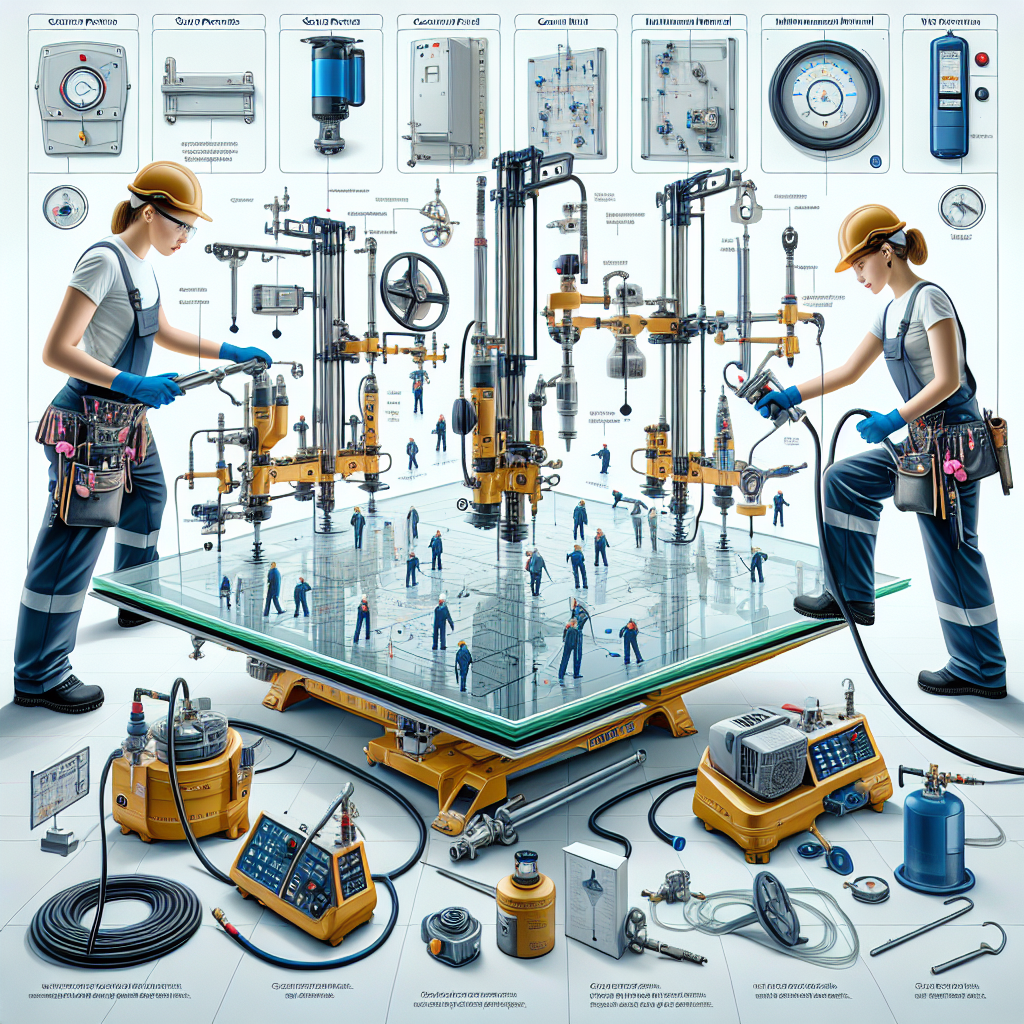

Pneumatic Glass Lifters: A Comprehensive Guide for Glaziers

Benefits of Using Pneumatic Glass Lifters in Glazing Projects

When it comes to glazing projects, the use of pneumatic glass lifters can greatly enhance efficiency and safety. These innovative tools have revolutionized the way glaziers handle and install glass, offering a range of benefits that make them an indispensable asset in the industry.

One of the primary advantages of using pneumatic glass lifters is their ability to lift and transport heavy glass panels with ease. Traditional methods of lifting glass often involve manual labor or the use of cumbersome machinery. However, pneumatic glass lifters utilize air pressure to create a vacuum seal, allowing glaziers to effortlessly lift and maneuver glass panels of various sizes and weights. This not only saves time and effort but also reduces the risk of injuries associated with manual lifting.

Furthermore, pneumatic glass lifters offer a high level of precision and control during glass installation. The vacuum seal created by these lifters ensures a secure grip on the glass, minimizing the chances of accidental drops or damage. Glaziers can easily position the glass panels exactly where they need to be, ensuring a perfect fit every time. This level of accuracy is particularly crucial when working on intricate or custom-designed projects that require precise alignment.

In addition to their lifting capabilities, pneumatic glass lifters also provide glaziers with increased flexibility and mobility on the job site. These lifters are typically lightweight and portable, allowing glaziers to easily transport them from one location to another. This means that glaziers can efficiently move between different areas of a project without the need for additional equipment or manpower. The ability to quickly and easily reposition the lifters also enables glaziers to work in tight or confined spaces, where traditional lifting methods may not be feasible.

Another significant benefit of using pneumatic glass lifters is the reduced risk of glass breakage. The vacuum seal created by these lifters ensures a secure grip on the glass, minimizing the chances of it slipping or shattering during transportation or installation. This not only saves glaziers from the hassle and expense of replacing broken glass but also reduces the potential for injuries caused by shattered glass fragments. By using pneumatic glass lifters, glaziers can confidently handle delicate glass panels without the fear of accidents or damage.

Furthermore, pneumatic glass lifters contribute to a more efficient workflow, allowing glaziers to complete projects in a shorter amount of time. The ease of use and quick setup of these lifters mean that glaziers can start working on glass installation immediately, without the need for time-consuming preparations or adjustments. This increased efficiency translates into cost savings for both glaziers and their clients, as projects can be completed more quickly and with fewer resources.

In conclusion, the benefits of using pneumatic glass lifters in glazing projects are numerous. From their ability to lift heavy glass panels with ease to their precision and control during installation, these tools have revolutionized the way glaziers work. The increased flexibility, reduced risk of glass breakage, and improved efficiency they offer make them an invaluable asset in the glazing industry. By incorporating pneumatic glass lifters into their workflow, glaziers can enhance safety, productivity, and overall project success.

How to Choose the Right Pneumatic Glass Lifter for Your Glazing Needs

Pneumatic Glass Lifters: A Comprehensive Guide for Glaziers

How to Choose the Right Pneumatic Glass Lifter for Your Glazing Needs

When it comes to working with glass, glaziers understand the importance of having the right tools for the job. One such tool that has revolutionized the industry is the pneumatic glass lifter. These devices are designed to make lifting and moving heavy glass panels a breeze, reducing the risk of injury and increasing efficiency. However, with so many options available on the market, it can be overwhelming for glaziers to choose the right pneumatic glass lifter for their specific needs. In this comprehensive guide, we will explore the key factors to consider when selecting a pneumatic glass lifter.

First and foremost, it is crucial to assess the weight capacity of the pneumatic glass lifter. Different lifters have varying weight limits, and it is essential to choose one that can handle the heaviest glass panels you typically work with. It is always better to opt for a lifter with a higher weight capacity than you currently require, as it allows for future growth and versatility.

Another important consideration is the size and dimensions of the glass panels you work with. Pneumatic glass lifters come in various configurations, including single cup, double cup, and multiple cup lifters. Single cup lifters are ideal for smaller glass panels, while double and multiple cup lifters are better suited for larger and heavier panels. Additionally, some lifters offer adjustable cup positions, allowing for greater flexibility when working with glass of different sizes.

The type of glass you work with is also a crucial factor to consider. Some pneumatic glass lifters are specifically designed for handling flat glass, while others are better suited for curved or irregularly shaped glass. It is essential to choose a lifter that is compatible with the type of glass you commonly work with to ensure optimal performance and safety.

In addition to weight capacity and glass type, it is important to consider the lifting mechanism of the pneumatic glass lifter. Some lifters use a vacuum system, while others utilize a suction cup mechanism. Vacuum systems are generally more powerful and provide a stronger grip on the glass, making them suitable for heavy-duty applications. Suction cup lifters, on the other hand, are more lightweight and portable, making them ideal for smaller projects or when mobility is a priority.

Furthermore, it is crucial to assess the safety features of the pneumatic glass lifter. Look for lifters that have built-in safety mechanisms such as audible alarms or visual indicators to alert the operator in case of any issues. Additionally, some lifters offer automatic release valves that prevent the glass from being dropped in the event of a power failure or loss of pressure.

Lastly, consider the overall quality and durability of the pneumatic glass lifter. Look for lifters made from high-quality materials that can withstand the rigors of daily use. It is also advisable to choose a lifter from a reputable manufacturer that offers warranties and after-sales support.

In conclusion, choosing the right pneumatic glass lifter is essential for glaziers to ensure efficient and safe glass handling. Consider factors such as weight capacity, glass type, lifting mechanism, safety features, and overall quality when making your decision. By carefully assessing your specific glazing needs and selecting a lifter that meets those requirements, you can enhance productivity, reduce the risk of injuries, and achieve superior results in your glass installation projects.

Safety Tips and Best Practices for Operating Pneumatic Glass Lifters

Safety Tips and Best Practices for Operating Pneumatic Glass Lifters

When it comes to working with heavy glass panels, safety should always be the top priority for glaziers. One tool that has revolutionized the glass installation process is the pneumatic glass lifter. These devices use compressed air to create a vacuum seal, allowing glaziers to lift and maneuver large glass panels with ease. However, like any piece of equipment, it is important to follow safety guidelines and best practices to ensure a smooth and accident-free operation.

First and foremost, before operating a pneumatic glass lifter, it is crucial to read and understand the manufacturer’s instructions. Each lifter may have specific requirements and limitations that need to be followed. Familiarize yourself with the lifter’s weight capacity, maximum lifting height, and any other specifications provided by the manufacturer. This will help you determine if the lifter is suitable for the task at hand and prevent any accidents or damage to the glass.

Before attaching the lifter to the glass panel, it is essential to inspect the lifter for any signs of damage or wear. Check the vacuum pads for cracks or tears and ensure that all the components are in good working condition. If any defects are found, the lifter should not be used until it has been repaired or replaced. Regular maintenance and inspections are crucial to keep the lifter in optimal condition and prevent any accidents during operation.

When attaching the lifter to the glass panel, make sure that the vacuum pads are clean and free from any debris or contaminants. Dust, dirt, or moisture can compromise the vacuum seal and lead to a potential failure. Clean the glass surface and the vacuum pads thoroughly before attaching the lifter to ensure a secure and reliable grip.

Once the lifter is attached to the glass panel, it is important to test the vacuum seal before lifting. Apply a moderate amount of pressure to the lifter to ensure that it is securely attached and that the vacuum pads are creating a strong seal. This step is crucial to prevent any unexpected detachment during the lifting process.

When lifting the glass panel, it is important to maintain a stable and balanced position. Make sure that the lifter is centered on the glass and that the weight is evenly distributed. Avoid sudden movements or jerks that could cause the glass to shift or become unstable. Slow and controlled movements are key to a safe and successful lift.

During the lifting process, it is important to be aware of any potential hazards or obstacles in the surrounding area. Clear the work area of any debris or objects that could interfere with the lifting operation. Communicate with your team members and establish clear signals or verbal cues to ensure a coordinated and safe lifting process.

Finally, when lowering the glass panel, do so with caution and control. Avoid releasing the vacuum seal abruptly, as this can cause the glass to drop or shatter. Lower the glass panel gently and ensure that it is securely placed before releasing the lifter.

In conclusion, operating a pneumatic glass lifter requires careful attention to safety guidelines and best practices. By following the manufacturer’s instructions, conducting regular inspections, and maintaining a stable and balanced position, glaziers can ensure a safe and efficient glass installation process. Remember to always prioritize safety and take the necessary precautions to protect yourself and others during the operation of a pneumatic glass lifter.