Benefits of Using a Vacuum Glass Lifter for Large-Scale Installations

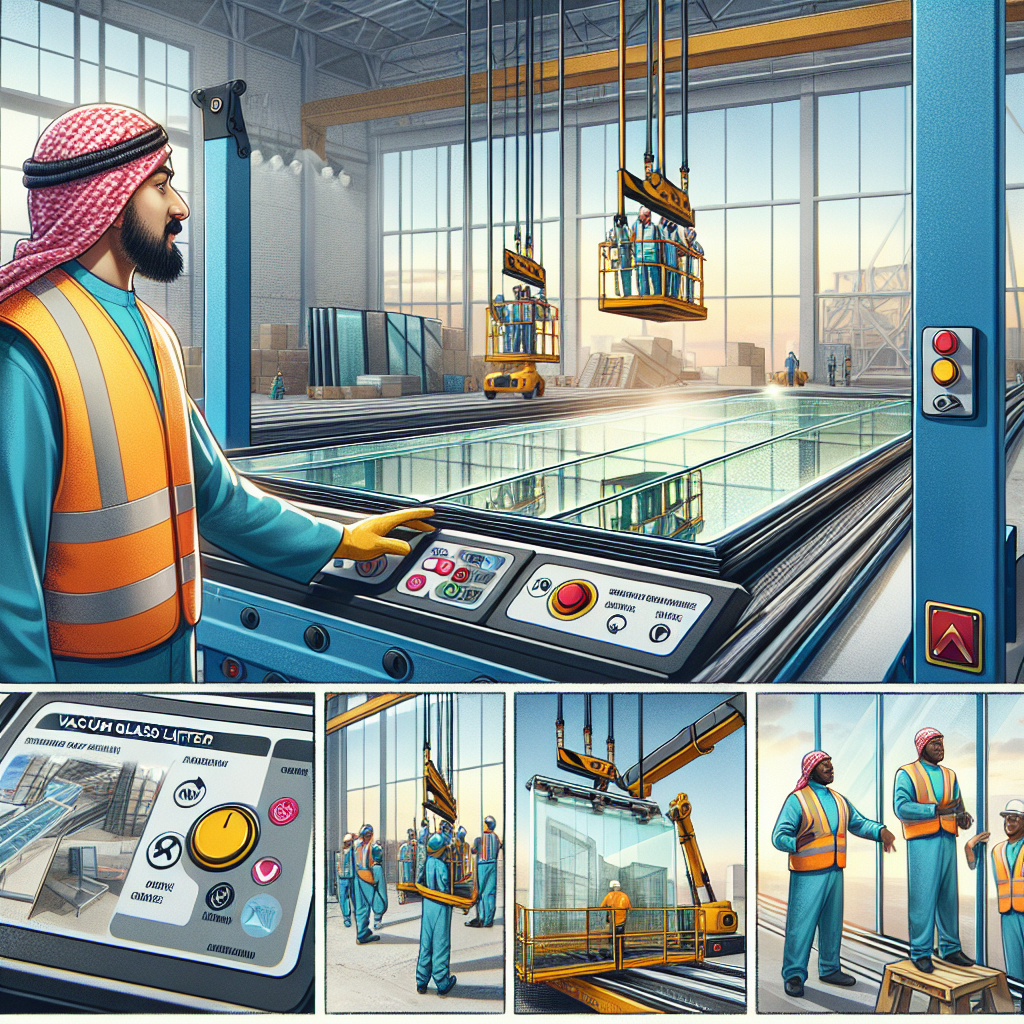

When it comes to large-scale installations, such as glass panels for skyscrapers or windows for commercial buildings, the use of a vacuum glass lifter can greatly simplify the process. This innovative tool offers numerous benefits that make it an essential piece of equipment for any construction or installation project.

One of the primary benefits of using a vacuum glass lifter is its ability to handle heavy loads with ease. These lifters are specifically designed to lift and transport large glass panels, which can weigh hundreds or even thousands of pounds. By utilizing the power of vacuum suction, the lifter securely attaches to the glass surface, allowing it to be lifted and moved effortlessly. This not only saves time and effort but also reduces the risk of accidents or injuries that can occur when manually lifting heavy objects.

Another advantage of using a vacuum glass lifter is its versatility. These lifters come in various sizes and configurations, allowing them to be used for a wide range of installation projects. Whether you need to lift a small window or a massive glass curtain wall, there is a vacuum glass lifter available to suit your needs. Additionally, many lifters come with adjustable suction cups, which can be positioned to accommodate different glass sizes and shapes. This flexibility makes the lifter a valuable tool for any installation job, regardless of its complexity.

In addition to their lifting capabilities, vacuum glass lifters also offer enhanced precision and control. The suction cups are designed to create a strong seal with the glass surface, ensuring a secure grip. This allows for precise positioning and alignment of the glass panels, which is crucial for achieving a seamless and professional-looking installation. The lifters also often come equipped with features such as tilt and rotation functions, further enhancing their maneuverability and control. With these advanced features, installers can easily adjust the position of the glass panels to fit perfectly into place, even in challenging or hard-to-reach areas.

Furthermore, using a vacuum glass lifter can significantly reduce the risk of damage to the glass panels during installation. The suction cups distribute the weight evenly across the surface, minimizing the risk of cracks, chips, or other forms of damage. This is particularly important when working with delicate or expensive glass materials, as any damage can result in costly replacements or repairs. By using a vacuum glass lifter, installers can ensure that the glass panels are handled with care and installed safely, minimizing the risk of accidents or mishaps.

In conclusion, the benefits of using a vacuum glass lifter for large-scale installations are numerous. From its ability to handle heavy loads with ease to its versatility and precision, this tool is an invaluable asset for any construction or installation project. By utilizing a vacuum glass lifter, installers can save time and effort, while also ensuring the safety and quality of the installation. Whether it’s for a skyscraper or a commercial building, a vacuum glass lifter is a must-have tool for any large-scale glass installation.

Step-by-Step Guide on Using a Vacuum Glass Lifter for Large-Scale Installations

How to Use a Vacuum Glass Lifter for Large-Scale Installations

When it comes to large-scale installations, such as glass panels for skyscrapers or windows for commercial buildings, using a vacuum glass lifter can make the job much easier and safer. A vacuum glass lifter is a specialized tool that uses suction cups to lift and transport heavy glass panels. In this step-by-step guide, we will walk you through the process of using a vacuum glass lifter for large-scale installations.

Step 1: Choose the Right Vacuum Glass Lifter

The first step in using a vacuum glass lifter is to choose the right one for your specific needs. Vacuum glass lifters come in various sizes and weight capacities, so it is important to select one that can handle the size and weight of the glass panels you will be working with. Additionally, make sure the lifter has a reliable and powerful vacuum pump to ensure a secure grip on the glass.

Step 2: Inspect the Glass Panels

Before using the vacuum glass lifter, thoroughly inspect the glass panels to ensure they are free from any defects or damage. Cracks, chips, or other imperfections can compromise the integrity of the glass and make it unsafe to handle. If you notice any issues, it is best to replace the glass panels before proceeding with the installation.

Step 3: Prepare the Vacuum Glass Lifter

Once you have chosen the right lifter and inspected the glass panels, it is time to prepare the vacuum glass lifter for use. Start by attaching the suction cups to the lifter, making sure they are securely fastened. Then, connect the lifter to a power source and turn on the vacuum pump. Allow the pump to run for a few minutes to ensure a strong vacuum is created.

Step 4: Position the Vacuum Glass Lifter

With the lifter prepared, carefully position it near the glass panel you will be lifting. Make sure the suction cups are aligned with the center of the glass and press them firmly against the surface. Once the cups are in place, engage the vacuum by activating the suction control valve. You should feel resistance as the cups adhere to the glass.

Step 5: Lift and Transport the Glass Panel

Once the vacuum is engaged, you can begin lifting and transporting the glass panel. Slowly raise the lifter using the control handles, keeping a steady and controlled motion. It is important to maintain a firm grip on the lifter and to move slowly to prevent any sudden shifts or jolts that could cause the glass to break or become dislodged.

Step 6: Position the Glass Panel for Installation

Once the glass panel is lifted, carefully position it in the desired location for installation. This may require the assistance of additional workers to guide and align the panel. Once the panel is in place, release the vacuum by opening the suction control valve. Slowly lower the lifter and detach the suction cups from the glass.

Using a vacuum glass lifter for large-scale installations can greatly simplify the process and improve safety. By following this step-by-step guide, you can ensure a smooth and successful installation of glass panels. Remember to always prioritize safety and take the necessary precautions when working with heavy and fragile materials.

Safety Precautions to Consider When Using a Vacuum Glass Lifter for Large-Scale Installations

Safety Precautions to Consider When Using a Vacuum Glass Lifter for Large-Scale Installations

When it comes to large-scale glass installations, using a vacuum glass lifter can greatly simplify the process. These powerful tools are designed to lift and transport heavy glass panels with ease, making them an essential piece of equipment for any construction or renovation project. However, it is important to remember that safety should always be the top priority when using a vacuum glass lifter. In this article, we will discuss some important safety precautions to consider when using a vacuum glass lifter for large-scale installations.

First and foremost, it is crucial to ensure that the vacuum glass lifter is in good working condition before each use. This means checking for any signs of damage or wear and tear, such as cracks in the suction cups or frayed cables. If any issues are detected, the lifter should be taken out of service immediately and repaired or replaced as necessary. Regular maintenance and inspections are also essential to keep the lifter in optimal condition and prevent any potential accidents.

Another important safety precaution is to always use the appropriate lifting capacity for the glass panels being installed. Each vacuum glass lifter is designed to handle a specific weight limit, and exceeding this limit can lead to equipment failure and serious injuries. It is crucial to carefully calculate the weight of the glass panels and ensure that the lifter being used is capable of safely lifting and transporting them. If in doubt, it is always better to err on the side of caution and use a lifter with a higher weight capacity.

Proper training is also essential when using a vacuum glass lifter. Operators should be thoroughly trained on how to safely operate the equipment, including how to attach and detach the suction cups, how to control the lifting and lowering functions, and how to maneuver the lifter without causing damage to the glass panels or surrounding structures. It is also important to train operators on how to recognize and respond to potential hazards, such as uneven or slippery surfaces, overhead obstacles, or sudden changes in weather conditions.

In addition to proper training, it is crucial to use personal protective equipment (PPE) when operating a vacuum glass lifter. This includes wearing safety gloves to protect hands from pinch points or sharp edges, safety goggles to protect eyes from flying debris, and sturdy footwear with slip-resistant soles to prevent slips and falls. It is also important to ensure that the work area is clear of any obstacles or debris that could pose a tripping hazard.

Lastly, it is important to always follow the manufacturer’s instructions and guidelines when using a vacuum glass lifter. This includes using the lifter only for its intended purpose, avoiding any modifications or alterations to the equipment, and adhering to any specific safety precautions or limitations outlined by the manufacturer. It is also important to keep the lifter’s user manual readily available for reference and to consult with the manufacturer or a qualified professional if any questions or concerns arise.

In conclusion, using a vacuum glass lifter for large-scale installations can greatly simplify the process of lifting and transporting heavy glass panels. However, it is crucial to prioritize safety when using this equipment. By ensuring that the lifter is in good working condition, using the appropriate lifting capacity, receiving proper training, using personal protective equipment, and following the manufacturer’s instructions, operators can minimize the risk of accidents and injuries. Remember, safety should always be the top priority when using a vacuum glass lifter for large-scale installations.