Increased Efficiency and Productivity in Construction with Vacuum Glass Lifters

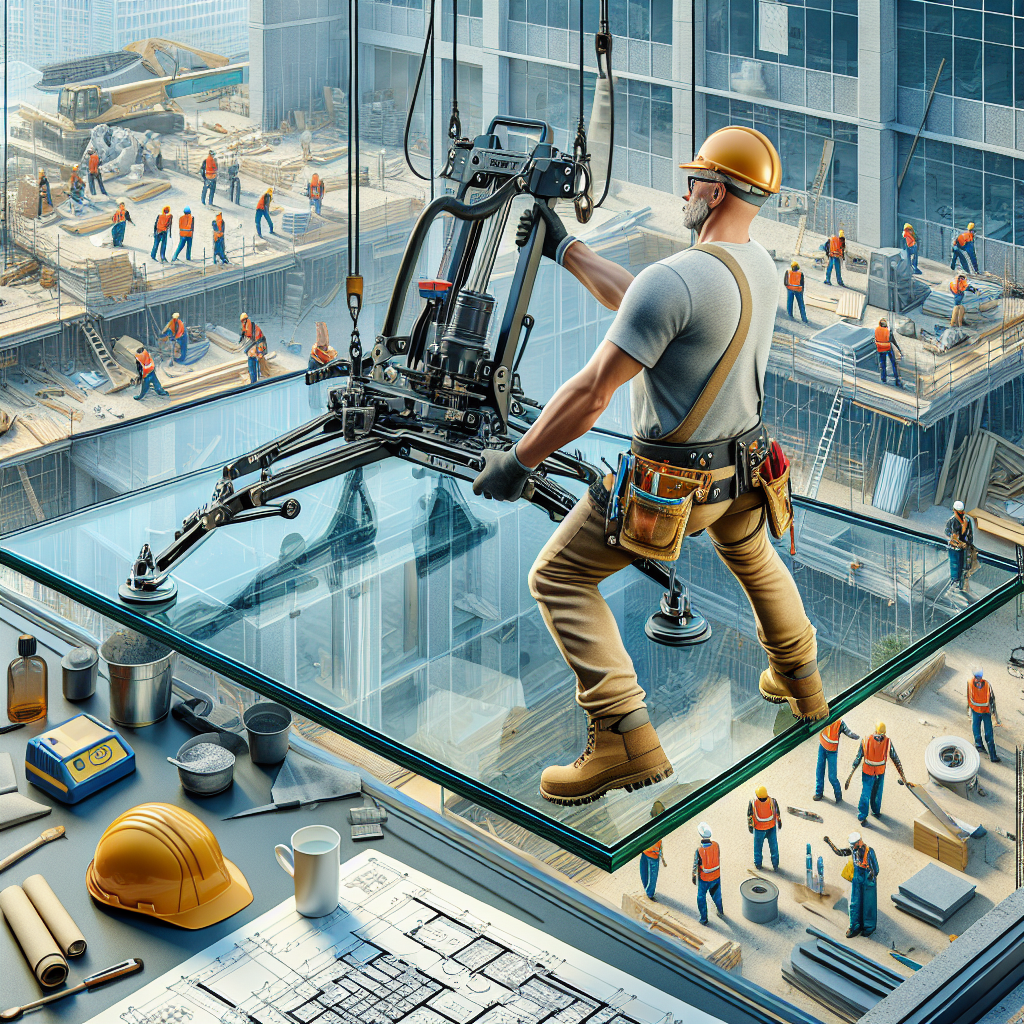

The construction industry is constantly evolving, with new technologies and tools being developed to improve efficiency and productivity. One such tool that has gained popularity in recent years is the vacuum glass lifter sucker. This innovative device has revolutionized the way glass panels are handled and installed in construction projects, offering a range of benefits that can greatly enhance efficiency and productivity.

One of the key advantages of using a vacuum glass lifter sucker is the increased speed at which glass panels can be moved and installed. Traditionally, glass panels were lifted and transported manually, which was not only time-consuming but also posed a significant risk to workers. With a vacuum glass lifter sucker, however, the process is streamlined and much faster. The device uses suction cups to securely grip the glass panel, allowing it to be lifted and moved with ease. This eliminates the need for manual lifting and reduces the risk of accidents or injuries.

In addition to speed, a vacuum glass lifter sucker also offers improved precision and control during the installation process. The device is designed to provide a secure grip on the glass panel, ensuring that it remains stable and in the desired position. This level of control is particularly important when working with large or heavy glass panels, as even the slightest misalignment can have significant consequences. By using a vacuum glass lifter sucker, construction workers can ensure that the glass panels are installed accurately and with minimal effort.

Another benefit of using a vacuum glass lifter sucker is the reduction in labor costs. Manual glass lifting and installation require a team of workers, which can be both time-consuming and expensive. With a vacuum glass lifter sucker, however, the process can be completed by a single operator. This not only reduces the number of workers required but also frees up resources that can be allocated to other tasks. As a result, construction projects can be completed more efficiently and at a lower cost.

Furthermore, the use of a vacuum glass lifter sucker can also contribute to a safer working environment. Manual glass lifting is a physically demanding task that can put a strain on workers’ bodies, leading to fatigue and potential injuries. By using a vacuum glass lifter sucker, the risk of musculoskeletal injuries is significantly reduced, as the device does the heavy lifting. This not only protects the health and well-being of workers but also reduces the likelihood of accidents or damage to the glass panels.

In conclusion, the use of a vacuum glass lifter sucker in construction offers a range of benefits that can greatly enhance efficiency and productivity. From increased speed and precision to reduced labor costs and improved safety, this innovative tool has revolutionized the way glass panels are handled and installed. As the construction industry continues to evolve, it is essential for companies to embrace new technologies and tools that can help them stay ahead of the competition. By incorporating a vacuum glass lifter sucker into their operations, construction companies can streamline their processes, save time and money, and ultimately deliver better results.

Enhanced Safety Measures and Risk Reduction with Vacuum Glass Lifters in Construction

The construction industry is known for its demanding and often dangerous work environments. Workers are constantly exposed to various risks and hazards, making safety a top priority. In recent years, there has been a growing trend towards the use of advanced technology and equipment to enhance safety measures and reduce risks on construction sites. One such technology that has gained popularity is the vacuum glass lifter sucker.

A vacuum glass lifter sucker is a device specifically designed for lifting and moving glass panels, windows, and other smooth and non-porous materials. It works by creating a vacuum seal between the lifter and the object, allowing it to be lifted and transported with ease. This innovative tool offers several benefits that contribute to enhanced safety measures and risk reduction in construction.

First and foremost, the use of a vacuum glass lifter sucker eliminates the need for manual lifting and carrying of heavy glass panels. In the past, construction workers had to rely on their physical strength to lift and transport these materials, which often led to strain and injuries. With the vacuum glass lifter sucker, the lifting process is mechanized, reducing the risk of musculoskeletal injuries and fatigue. This not only protects the workers’ health but also improves overall productivity on the construction site.

Furthermore, the vacuum glass lifter sucker provides a secure and stable grip on the glass panels, minimizing the risk of accidents and breakages. Traditional methods of lifting glass panels often involved the use of clamps or suction cups, which were not always reliable and could easily slip or detach. This posed a significant danger to both the workers and the materials being transported. The vacuum glass lifter sucker, on the other hand, creates a strong vacuum seal that firmly holds the glass panel in place, ensuring safe and secure lifting and movement.

Another advantage of using a vacuum glass lifter sucker is its versatility. It can be used for a wide range of applications, including the installation of windows, glass walls, and curtain walls. This versatility allows construction workers to handle different types and sizes of glass panels with ease, reducing the need for multiple tools and equipment. By streamlining the lifting process, the vacuum glass lifter sucker helps to save time and effort, ultimately improving efficiency and reducing the risk of errors or accidents.

In addition to these benefits, the vacuum glass lifter sucker also offers increased control and precision during the lifting process. It allows for smooth and controlled movements, making it easier to position the glass panels accurately. This is particularly important when working in tight or confined spaces, where even a slight misalignment can have significant consequences. By providing better control and precision, the vacuum glass lifter sucker helps to minimize the risk of damage to the materials and surrounding structures, ensuring a safer and more efficient construction process.

In conclusion, the use of a vacuum glass lifter sucker in construction offers several benefits that contribute to enhanced safety measures and risk reduction. By eliminating manual lifting, providing a secure grip, offering versatility, and increasing control and precision, this innovative tool helps to protect workers’ health, prevent accidents, and improve overall productivity. As the construction industry continues to prioritize safety, the vacuum glass lifter sucker is becoming an essential piece of equipment on construction sites worldwide.

Cost Savings and Time Optimization through the Use of Vacuum Glass Lifter Suckers in Construction

The construction industry is constantly evolving, with new technologies and tools being developed to improve efficiency and safety on job sites. One such tool that has gained popularity in recent years is the vacuum glass lifter sucker. This innovative device offers numerous benefits, including cost savings and time optimization, making it a valuable asset for construction projects.

One of the primary advantages of using a vacuum glass lifter sucker is the cost savings it provides. Traditional methods of lifting and installing glass panels often require the use of heavy machinery or multiple workers. This not only increases labor costs but also poses a risk of damage to the glass, resulting in additional expenses. In contrast, a vacuum glass lifter sucker eliminates the need for excessive manpower and heavy equipment, reducing labor costs significantly. Moreover, the gentle suction cups of the lifter ensure that the glass is lifted and transported without any damage, minimizing the risk of costly replacements or repairs.

In addition to cost savings, the use of a vacuum glass lifter sucker also optimizes time on construction sites. Installing glass panels manually can be a time-consuming process, requiring careful coordination and precision. However, with a vacuum glass lifter sucker, the installation becomes much quicker and more efficient. The device’s suction cups securely hold the glass, allowing it to be lifted and positioned with ease. This eliminates the need for time-consuming adjustments and ensures that the glass is installed accurately on the first attempt. As a result, construction projects can be completed faster, reducing overall project timelines and allowing for quicker occupancy or turnover.

Furthermore, the use of a vacuum glass lifter sucker enhances safety on construction sites. Lifting and installing glass panels manually can be a hazardous task, with the risk of accidents and injuries. The vacuum glass lifter sucker eliminates the need for workers to physically handle the glass, reducing the risk of strains, sprains, or falls. The device’s secure grip on the glass ensures stability during transportation and installation, minimizing the chances of accidents or damage. By prioritizing safety, construction companies can avoid costly workplace injuries and maintain a positive reputation within the industry.

Another advantage of using a vacuum glass lifter sucker is its versatility. This tool can be used for various types of glass panels, including large and heavy ones. Whether it’s for windows, doors, or curtain walls, the vacuum glass lifter sucker can handle the task efficiently. Its adjustable suction cups allow for customization based on the size and weight of the glass, ensuring a secure grip and safe transportation. This versatility makes the device a valuable investment for construction companies, as it can be utilized across multiple projects and applications.

In conclusion, the use of a vacuum glass lifter sucker in construction offers numerous benefits. From cost savings and time optimization to enhanced safety and versatility, this innovative tool has revolutionized the way glass panels are handled and installed. By investing in a vacuum glass lifter sucker, construction companies can streamline their operations, reduce expenses, and improve overall project efficiency. As the industry continues to evolve, it is crucial for construction professionals to embrace new technologies that can drive progress and success.