Benefits of Using a Vacuum Glass Lifter Sucker for Efficient Material Handling

Efficiency is a key factor in any industry, and when it comes to material handling, finding ways to maximize efficiency is crucial. One tool that can greatly contribute to efficiency in material handling is a vacuum glass lifter sucker. This innovative device offers numerous benefits that can streamline the process of moving and handling glass and other materials.

One of the primary benefits of using a vacuum glass lifter sucker is its ability to securely grip and lift heavy objects. Traditional methods of lifting and moving glass often involve manual labor, which can be time-consuming and physically demanding. With a vacuum glass lifter sucker, however, the process becomes much easier and less strenuous. The device uses suction to create a strong grip on the glass, allowing it to be lifted and moved with minimal effort. This not only saves time but also reduces the risk of injury to workers.

Another advantage of using a vacuum glass lifter sucker is its versatility. These devices are designed to handle a wide range of materials, including glass, metal, plastic, and even stone. This means that they can be used in a variety of industries, from construction and manufacturing to automotive and aerospace. The ability to handle different types of materials makes the vacuum glass lifter sucker a valuable tool for any business that deals with heavy objects.

In addition to its versatility, a vacuum glass lifter sucker also offers precision and control. The device is equipped with adjustable suction cups that can be positioned to fit the shape and size of the material being lifted. This allows for a secure grip and ensures that the material is held in place during transport. The precision and control provided by the vacuum glass lifter sucker not only increase efficiency but also reduce the risk of damage to the material.

Furthermore, using a vacuum glass lifter sucker can help save space and improve workflow. Traditional methods of material handling often require large, bulky equipment that takes up valuable floor space. In contrast, a vacuum glass lifter sucker is compact and can be easily maneuvered in tight spaces. This means that businesses can optimize their workspace and create a more efficient workflow. The compact design of the device also allows for easy transportation and storage when not in use.

Lastly, a vacuum glass lifter sucker can contribute to cost savings. By reducing the need for manual labor and minimizing the risk of damage to materials, businesses can save both time and money. Additionally, the durability and longevity of these devices mean that they can be used for years without the need for frequent repairs or replacements. This makes them a cost-effective investment for any business looking to improve efficiency in material handling.

In conclusion, a vacuum glass lifter sucker offers numerous benefits for efficient material handling. From its ability to securely grip and lift heavy objects to its versatility and precision, this device can streamline the process of moving and handling materials. Its compact design and cost-saving features further contribute to its value. By incorporating a vacuum glass lifter sucker into their operations, businesses can maximize efficiency and improve their overall productivity.

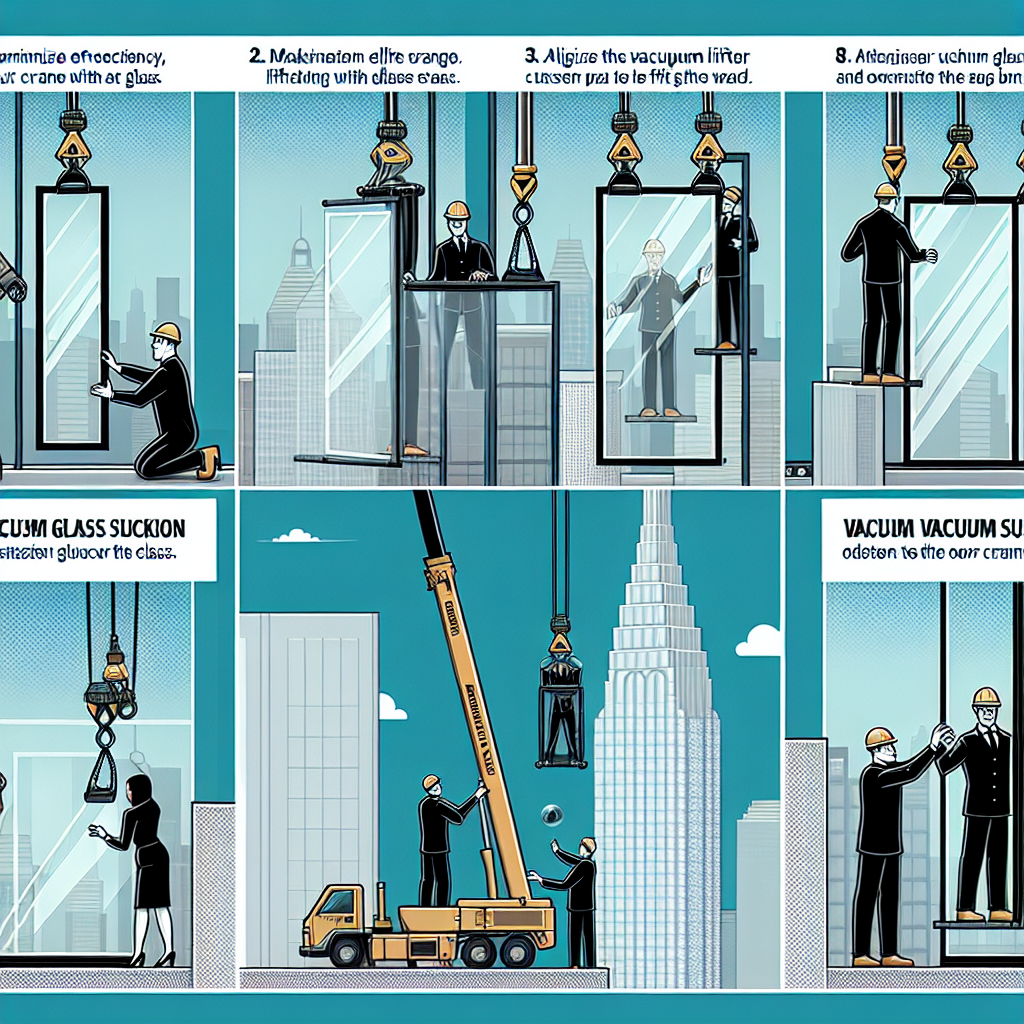

Tips and Techniques for Optimizing Efficiency with a Vacuum Glass Lifter Sucker

A vacuum glass lifter sucker is a powerful tool that can greatly enhance efficiency in various industries. Whether you are in the construction, manufacturing, or logistics sector, utilizing this equipment can help streamline your operations and save valuable time and resources. In this article, we will explore some tips and techniques for optimizing efficiency with a vacuum glass lifter sucker.

First and foremost, it is crucial to choose the right type of vacuum glass lifter sucker for your specific needs. There are various models available, each designed for different applications. Consider factors such as the weight and size of the glass or other materials you will be handling, as well as any specific requirements or limitations of your work environment. By selecting the most suitable lifter sucker, you can ensure maximum efficiency and safety.

Once you have chosen the appropriate vacuum glass lifter sucker, it is essential to properly maintain and inspect it regularly. This includes checking for any signs of wear and tear, ensuring that all components are functioning correctly, and cleaning the equipment after each use. Regular maintenance not only prolongs the lifespan of the lifter sucker but also ensures optimal performance and minimizes the risk of accidents or malfunctions.

Another tip for maximizing efficiency with a vacuum glass lifter sucker is to train your employees on its proper usage. Familiarize them with the equipment’s features, controls, and safety protocols. Provide comprehensive training on how to handle different types of glass or materials, as well as how to secure and release them using the lifter sucker. By ensuring that your employees are well-trained, you can minimize the risk of accidents and errors, thereby increasing overall efficiency.

Furthermore, it is crucial to plan and organize your workflow effectively when using a vacuum glass lifter sucker. Before starting any task, assess the layout of your work area and determine the most efficient way to move and position the glass or materials. Consider factors such as the weight, size, and fragility of the items, as well as any obstacles or obstructions that may be present. By carefully planning your workflow, you can minimize unnecessary movements and optimize the use of the lifter sucker, ultimately saving time and effort.

In addition to proper planning, communication among team members is vital for maximizing efficiency. Ensure that everyone involved in the task is aware of their roles and responsibilities, as well as any specific instructions or precautions. Establish clear communication channels and encourage open dialogue to address any concerns or issues promptly. Effective communication not only enhances efficiency but also promotes a safer working environment.

Lastly, consider investing in additional accessories or attachments that can further enhance the efficiency of your vacuum glass lifter sucker. For example, some models offer adjustable suction cups or extension arms, allowing you to handle a wider range of materials or reach higher heights. Additionally, there are specialized attachments available for lifting curved or irregularly shaped glass. By utilizing these accessories, you can expand the capabilities of your lifter sucker and optimize its efficiency for various tasks.

In conclusion, a vacuum glass lifter sucker is a valuable tool for maximizing efficiency in various industries. By choosing the right equipment, maintaining it properly, training your employees, planning your workflow, promoting effective communication, and utilizing additional accessories, you can optimize the performance of your lifter sucker and streamline your operations. Implement these tips and techniques to enhance efficiency and achieve greater productivity in your workplace.

Common Mistakes to Avoid When Using a Vacuum Glass Lifter Sucker for Maximum Efficiency

When it comes to maximizing efficiency with a vacuum glass lifter sucker, there are several common mistakes that should be avoided. These mistakes can hinder the effectiveness of the lifter and prevent you from achieving the desired results. By being aware of these mistakes and taking steps to avoid them, you can ensure that you are getting the most out of your vacuum glass lifter sucker.

One common mistake is not properly inspecting the glass surface before using the lifter. It is important to ensure that the glass is clean and free from any debris or contaminants that could interfere with the suction. Before attaching the lifter, take the time to thoroughly clean the glass surface and remove any dirt or dust. This will help to create a strong seal and ensure that the lifter can effectively lift and transport the glass.

Another mistake is not properly positioning the lifter on the glass surface. It is important to place the lifter in the correct position to ensure maximum efficiency. The lifter should be centered on the glass and positioned in a way that allows for an even distribution of weight. This will help to prevent any imbalances and ensure that the lifter can securely hold the glass without any risk of it slipping or falling.

In addition to proper positioning, it is also important to avoid overloading the lifter. Each vacuum glass lifter sucker has a specific weight capacity that should not be exceeded. Overloading the lifter can put unnecessary strain on the suction cups and decrease their effectiveness. Before using the lifter, make sure to check the weight capacity and ensure that the glass being lifted falls within the recommended range. If the glass is too heavy, consider using a different lifter or seeking assistance to avoid any potential accidents or damage.

Another mistake to avoid is not properly maintaining the lifter. Like any tool, a vacuum glass lifter sucker requires regular maintenance to ensure optimal performance. This includes regularly inspecting the suction cups for any signs of wear or damage and replacing them as needed. It is also important to clean the lifter after each use to remove any dirt or debris that may have accumulated. By properly maintaining the lifter, you can extend its lifespan and ensure that it continues to function at its best.

Lastly, it is important to avoid rushing when using a vacuum glass lifter sucker. Taking the time to properly position the lifter, inspect the glass surface, and ensure that everything is in order will help to prevent any accidents or mishaps. Rushing through the process can lead to mistakes and potentially damage the glass or the lifter itself. By being patient and thorough, you can maximize efficiency and achieve the desired results.

In conclusion, there are several common mistakes that should be avoided when using a vacuum glass lifter sucker for maximum efficiency. These include not properly inspecting the glass surface, not properly positioning the lifter, overloading the lifter, not properly maintaining the lifter, and rushing through the process. By being aware of these mistakes and taking steps to avoid them, you can ensure that you are getting the most out of your vacuum glass lifter sucker and achieving optimal results.