Increased Efficiency and Productivity in High-Rise Construction Projects

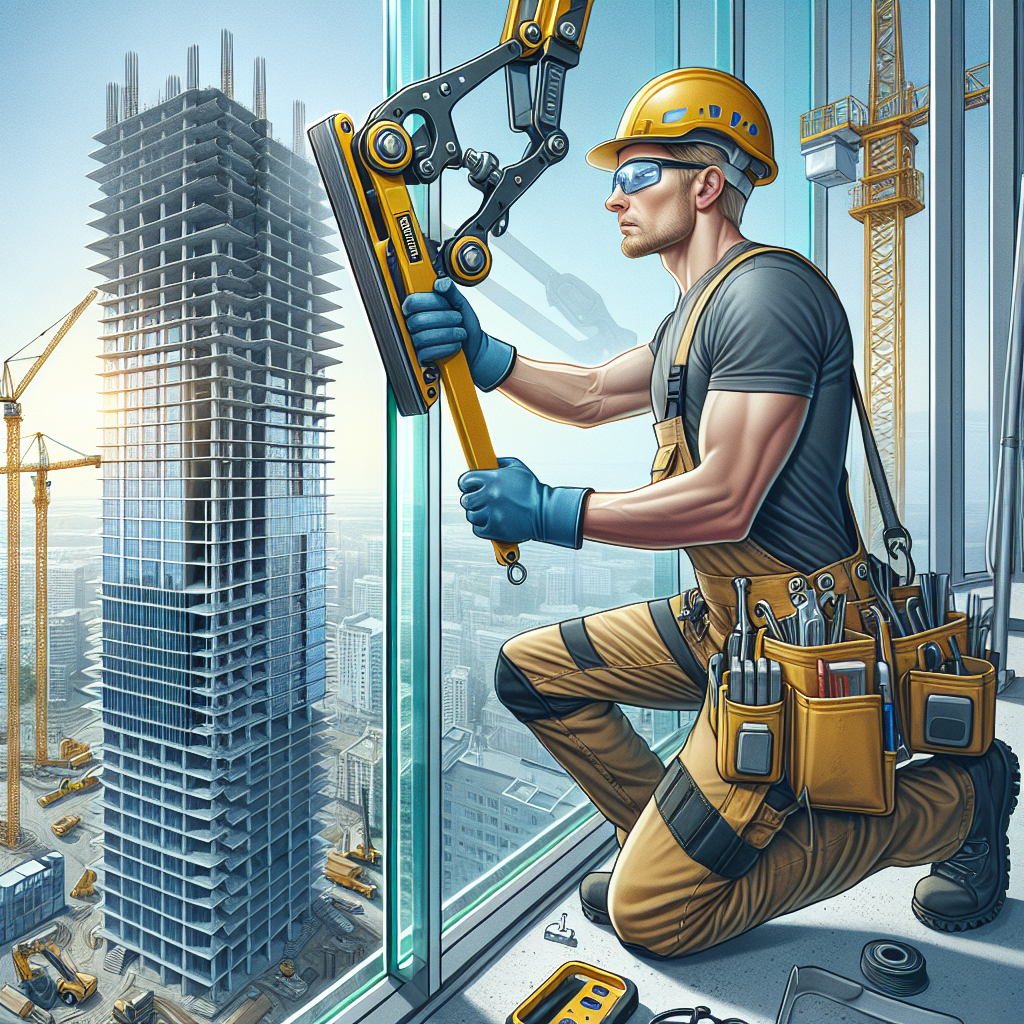

The construction industry is constantly evolving, with new technologies and equipment being developed to improve efficiency and productivity. One such innovation that has gained popularity in recent years is the glass lifter sucker. This device, also known as a vacuum lifter, is specifically designed to handle and transport large glass panels in high-rise construction projects. In this article, we will explore the advantages of using a glass lifter sucker in high-rise projects, focusing on the increased efficiency and productivity it brings to the construction site.

One of the main advantages of using a glass lifter sucker is the significant increase in efficiency it offers. Traditionally, the installation of glass panels in high-rise buildings was a labor-intensive and time-consuming process. Workers had to manually lift and position each panel, often requiring multiple individuals to handle the heavy and fragile material. This not only slowed down the construction process but also posed a safety risk to the workers involved.

With the introduction of glass lifter suckers, the process of handling and installing glass panels has been revolutionized. These devices are equipped with powerful suction cups that securely grip the glass, allowing it to be lifted and moved with ease. This eliminates the need for manual lifting and reduces the risk of accidents or injuries. Moreover, glass lifter suckers are designed to be operated by a single person, further streamlining the installation process.

In addition to increased efficiency, the use of glass lifter suckers also enhances productivity on high-rise construction projects. The ability to quickly and safely transport glass panels means that workers can install them at a much faster pace. This not only saves time but also allows for more panels to be installed in a given timeframe. As a result, the overall construction schedule is expedited, enabling the project to be completed sooner.

Furthermore, the use of glass lifter suckers eliminates the need for additional manpower. In the past, multiple workers were required to handle and position glass panels, which often led to delays and inefficiencies. With the introduction of this innovative device, a single operator can easily maneuver and install the panels, reducing the need for additional labor. This not only saves costs but also allows workers to focus on other tasks, further increasing productivity on the construction site.

Another advantage of using glass lifter suckers in high-rise projects is the improved safety they provide. The suction cups on these devices are designed to securely grip the glass, preventing it from slipping or falling during transportation. This significantly reduces the risk of accidents and injuries, ensuring the well-being of workers and the integrity of the glass panels. Additionally, glass lifter suckers are equipped with safety features such as alarms and indicators that alert the operator in case of any issues or malfunctions.

In conclusion, the use of glass lifter suckers in high-rise construction projects offers numerous advantages, particularly in terms of increased efficiency and productivity. These devices streamline the process of handling and installing glass panels, eliminating the need for manual lifting and reducing the risk of accidents. Moreover, they allow for faster installation and expedite the overall construction schedule. Additionally, glass lifter suckers enhance safety on the construction site, ensuring the well-being of workers and the integrity of the glass panels. With these benefits in mind, it is clear that the use of glass lifter suckers is a valuable investment for any high-rise construction project.

Enhanced Safety Measures and Risk Reduction with Glass Lifter Suckers

The construction industry is constantly evolving, with new technologies and equipment being developed to improve efficiency and safety. One such innovation that has gained popularity in recent years is the glass lifter sucker. This device, also known as a vacuum lifter or glass sucker, is specifically designed to handle and transport large glass panels in high-rise projects. In this article, we will explore the advantages of using a glass lifter sucker in such projects, focusing on the enhanced safety measures and risk reduction it offers.

One of the primary advantages of using a glass lifter sucker is the increased safety it provides for workers. In high-rise projects, working at great heights poses significant risks, and handling large glass panels adds an additional layer of danger. Traditional methods of lifting and moving glass panels often involve manual labor, which can be physically demanding and prone to accidents. However, with a glass lifter sucker, the process becomes much safer and more efficient.

The glass lifter sucker utilizes a vacuum system to create a strong suction force, allowing it to securely grip onto glass panels. This eliminates the need for workers to physically lift and carry the heavy panels, reducing the risk of strain or injury. Additionally, the suction force ensures a firm grip on the glass, minimizing the chances of accidental drops or slips during transportation. This enhanced safety measure not only protects workers from potential harm but also prevents damage to the glass panels, saving both time and money.

Furthermore, the use of a glass lifter sucker significantly reduces the risk of damage to the surrounding structures and materials. When manually handling glass panels, there is always a possibility of accidental collisions or impacts, which can result in costly repairs or delays in the project. However, the precise control offered by the glass lifter sucker minimizes the chances of such incidents occurring. The device allows for smooth and controlled movements, ensuring that the glass panels are transported without causing any damage to the building or other materials.

In addition to the safety benefits, using a glass lifter sucker also improves the overall efficiency of high-rise projects. The device is designed to handle large glass panels with ease, reducing the time and effort required for installation. With traditional methods, multiple workers may be needed to lift and position the panels, which can be time-consuming and labor-intensive. However, a glass lifter sucker can be operated by a single person, streamlining the process and allowing for faster installation.

Moreover, the glass lifter sucker is versatile and adaptable to different project requirements. It can be adjusted to accommodate various sizes and shapes of glass panels, making it suitable for a wide range of high-rise projects. This flexibility not only saves time but also reduces the need for additional equipment or manpower, further enhancing the efficiency of the construction process.

In conclusion, the use of a glass lifter sucker in high-rise projects offers numerous advantages, particularly in terms of enhanced safety measures and risk reduction. By eliminating the need for manual lifting and providing a secure grip on glass panels, the device protects workers from potential injuries and prevents damage to the glass and surrounding structures. Additionally, the efficiency and versatility of the glass lifter sucker contribute to faster installation and overall project success. As the construction industry continues to prioritize safety and efficiency, the adoption of this innovative technology is likely to become increasingly common in high-rise projects.

Cost Savings and Time Optimization through the Use of Glass Lifter Suckers

The use of glass lifter suckers in high-rise projects offers several advantages, including cost savings and time optimization. These devices, also known as vacuum lifters or suction cups, are specifically designed to lift and transport large glass panels safely and efficiently. By utilizing this technology, construction companies can streamline their operations and achieve significant benefits.

One of the primary advantages of using a glass lifter sucker is the cost savings it provides. Traditional methods of lifting and installing glass panels often require the use of cranes or other heavy machinery. These machines can be expensive to rent or purchase, and their operation requires skilled operators. In contrast, glass lifter suckers are relatively affordable and can be operated by a single worker. This eliminates the need for additional machinery and reduces labor costs, resulting in substantial savings for construction companies.

Furthermore, glass lifter suckers offer time optimization benefits. The installation of glass panels in high-rise projects can be a time-consuming process, especially when using traditional methods. The use of cranes or other machinery often requires careful planning and coordination, which can lead to delays and inefficiencies. In contrast, glass lifter suckers are designed to be quick and easy to use. They can be attached to glass panels in a matter of seconds, allowing for rapid installation. This not only speeds up the construction process but also enables workers to complete more tasks in a shorter amount of time.

In addition to cost savings and time optimization, glass lifter suckers also enhance safety on high-rise projects. The lifting and installation of large glass panels can be hazardous, particularly when using traditional methods. The use of cranes or other machinery introduces the risk of accidents and injuries. Glass lifter suckers, on the other hand, are specifically designed to ensure the safe handling of glass panels. They utilize vacuum technology to create a secure grip on the glass, minimizing the risk of slippage or dropping. This reduces the likelihood of accidents and injuries, creating a safer working environment for construction workers.

Moreover, glass lifter suckers are versatile and can be used in a variety of high-rise projects. They are not limited to the installation of glass panels but can also be used for other tasks, such as moving and positioning glass partitions or windows. This versatility makes them a valuable tool for construction companies, as they can be utilized throughout the entire project, from start to finish.

In conclusion, the use of glass lifter suckers in high-rise projects offers several advantages. These devices provide cost savings by eliminating the need for expensive machinery and reducing labor costs. They also optimize time by enabling rapid installation and increasing productivity. Additionally, glass lifter suckers enhance safety by minimizing the risk of accidents and injuries. Their versatility further adds to their value, as they can be used for various tasks throughout the project. By incorporating glass lifter suckers into their operations, construction companies can streamline their processes and achieve significant benefits.