Increased Efficiency and Productivity with Vacuum Glass Lifters

Why Every Construction Site Needs a Vacuum Glass Lifter

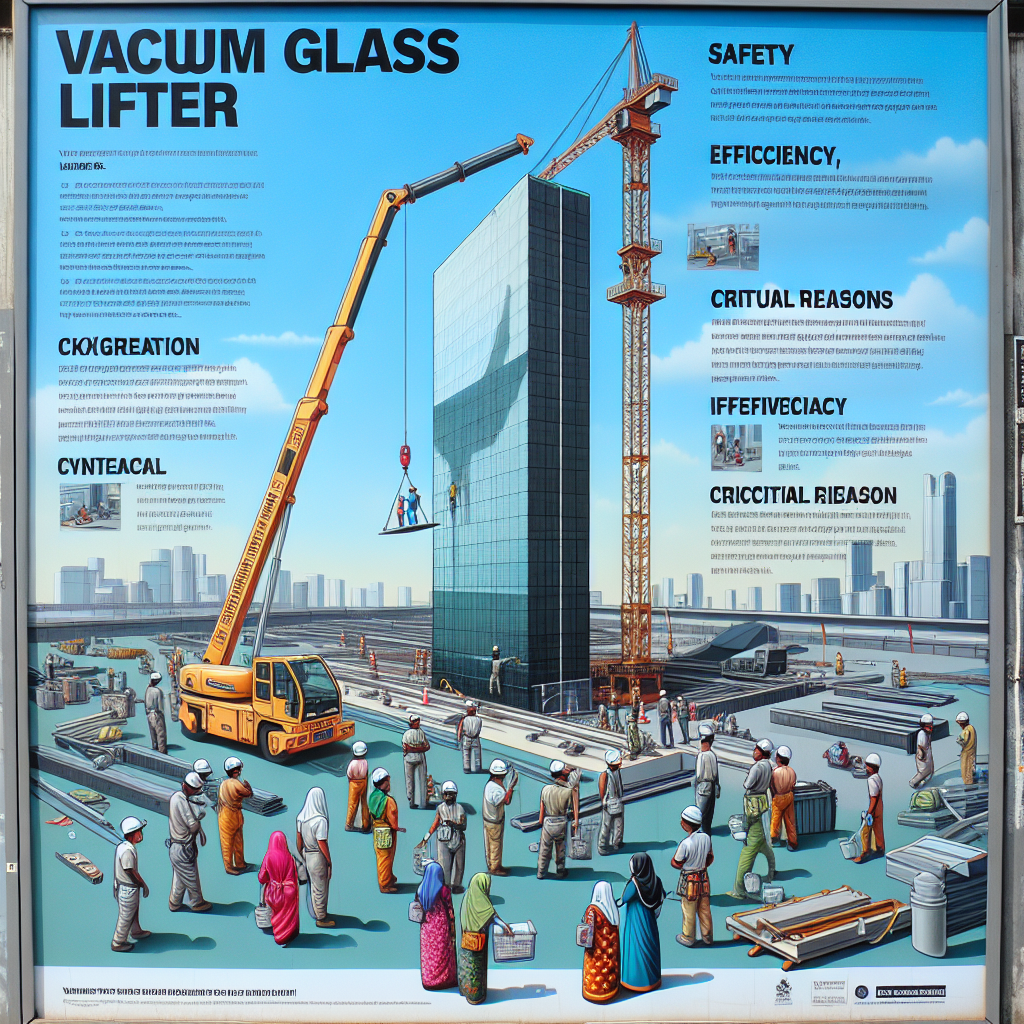

Construction sites are bustling with activity, with workers engaged in various tasks to ensure the successful completion of a project. One crucial aspect of construction is the installation of glass panels, which not only adds aesthetic appeal but also allows natural light to flood the interior spaces. However, handling and installing glass panels can be a challenging and time-consuming task. This is where vacuum glass lifters come into play, offering increased efficiency and productivity on construction sites.

One of the primary advantages of using a vacuum glass lifter is the ability to handle heavy glass panels with ease. Traditional methods of glass installation often involve multiple workers manually lifting and maneuvering the glass, which can be physically demanding and time-consuming. With a vacuum glass lifter, a single operator can effortlessly lift and transport glass panels, reducing the need for additional manpower and minimizing the risk of injuries.

Furthermore, vacuum glass lifters are designed to provide a secure grip on glass panels, ensuring their safe transportation and installation. The suction cups on the lifter create a vacuum seal, firmly holding the glass in place. This eliminates the risk of the glass slipping or falling during transportation, reducing the chances of accidents and damage to the glass panels. The secure grip provided by vacuum glass lifters also allows for precise positioning of the glass, ensuring accurate installation and alignment.

In addition to increased safety, vacuum glass lifters also contribute to improved productivity on construction sites. The efficiency of these lifters allows for faster installation of glass panels, reducing the overall project timeline. With traditional methods, the time spent on lifting and maneuvering glass panels can be significant, causing delays in other construction activities. By using a vacuum glass lifter, construction workers can quickly and efficiently move glass panels into position, allowing other tasks to progress smoothly.

Moreover, vacuum glass lifters are versatile tools that can be used for various glass installation tasks. Whether it is installing large windows, glass doors, or even curtain walls, these lifters can handle a wide range of glass panel sizes and shapes. This versatility eliminates the need for multiple lifting devices, streamlining the construction process and reducing equipment costs.

Another advantage of vacuum glass lifters is their ease of use. These lifters are designed to be user-friendly, with intuitive controls and ergonomic features. Operators can quickly learn how to operate the lifter, minimizing the need for extensive training. This ease of use also reduces the chances of operator error, ensuring the safe and efficient handling of glass panels.

In conclusion, vacuum glass lifters offer numerous benefits for construction sites. From increased efficiency and productivity to enhanced safety and ease of use, these lifters are essential tools for handling and installing glass panels. By investing in a vacuum glass lifter, construction companies can streamline their operations, reduce costs, and ensure the successful completion of projects. With the growing demand for glass in modern architecture, having a vacuum glass lifter is no longer a luxury but a necessity for every construction site.

Enhanced Safety Measures on Construction Sites with Vacuum Glass Lifters

Why Every Construction Site Needs a Vacuum Glass Lifter

Construction sites are known for their bustling activity, with workers engaged in various tasks to bring a project to fruition. However, amidst the hustle and bustle, safety should always be a top priority. One area where enhanced safety measures can be implemented is the handling of glass panels, which are commonly used in modern construction. Vacuum glass lifters have emerged as a valuable tool in ensuring the safety of workers and the integrity of glass installations on construction sites.

One of the primary reasons why vacuum glass lifters are essential on construction sites is their ability to reduce the risk of accidents and injuries. Traditional methods of glass handling, such as manual lifting or the use of slings and clamps, can be hazardous and prone to human error. The sheer weight and fragility of glass panels make them susceptible to slipping, dropping, or shattering, leading to severe injuries or even fatalities. Vacuum glass lifters, on the other hand, provide a secure and controlled grip on the glass, minimizing the chances of accidents and ensuring the safety of workers.

Moreover, vacuum glass lifters offer increased efficiency and productivity on construction sites. With their ability to lift and transport glass panels with ease, these devices save valuable time and effort. Manual handling of glass panels is not only physically demanding but also time-consuming. By using vacuum glass lifters, workers can complete glass installation tasks more quickly, allowing them to focus on other critical aspects of the construction project. This increased efficiency translates into cost savings for construction companies, as projects can be completed within shorter timeframes.

Another advantage of vacuum glass lifters is their versatility. These devices can be used for a wide range of glass panel sizes and shapes, making them suitable for various construction projects. Whether it is large floor-to-ceiling windows or intricate glass facades, vacuum glass lifters can handle them all. This versatility eliminates the need for multiple lifting tools, simplifying the logistics and reducing the equipment required on construction sites. Additionally, vacuum glass lifters can be easily adjusted to accommodate different angles and orientations, ensuring precise and accurate glass installations.

In addition to their safety and efficiency benefits, vacuum glass lifters also contribute to the overall quality of glass installations. The controlled grip provided by these devices minimizes the risk of damage to glass panels during handling and transportation. This is particularly crucial for high-end projects where flawless glass installations are essential. By using vacuum glass lifters, construction companies can ensure that glass panels are delivered and installed without any scratches, chips, or cracks, enhancing the aesthetic appeal and longevity of the finished structure.

In conclusion, vacuum glass lifters have become an indispensable tool on construction sites due to their ability to enhance safety, efficiency, and quality. By reducing the risk of accidents and injuries, these devices protect the well-being of workers and prevent costly damages. Their versatility and ease of use make them suitable for various glass panel sizes and shapes, simplifying logistics and reducing equipment requirements. Furthermore, vacuum glass lifters contribute to the overall quality of glass installations, ensuring flawless results. With these benefits in mind, it is clear why every construction site should invest in a vacuum glass lifter to improve safety measures and streamline glass handling processes.

Cost Savings and Time Optimization with Vacuum Glass Lifters

Why Every Construction Site Needs a Vacuum Glass Lifter

Cost Savings and Time Optimization with Vacuum Glass Lifters

In the construction industry, time is money. Every minute wasted on inefficient processes or equipment can result in significant financial losses. That’s why it’s crucial for construction sites to invest in tools and machinery that can streamline operations and maximize productivity. One such tool that has proven to be indispensable in the industry is the vacuum glass lifter.

A vacuum glass lifter is a specialized piece of equipment designed to lift and transport glass panels with ease and precision. It utilizes the power of suction to securely grip the glass, eliminating the need for manual lifting or the use of cumbersome and potentially dangerous equipment like cranes or forklifts. This not only reduces the risk of accidents and injuries but also significantly speeds up the installation process.

One of the key advantages of using a vacuum glass lifter is the cost savings it offers. Traditional methods of glass installation often require multiple workers and heavy machinery, which can be expensive to operate and maintain. In contrast, a vacuum glass lifter can be operated by just one person, reducing labor costs and freeing up resources that can be allocated to other areas of the construction project.

Furthermore, the use of a vacuum glass lifter eliminates the need for additional equipment such as slings, straps, or clamps, which can add to the overall cost of the project. The lifter’s suction cups are specifically designed to securely hold the glass panels without causing any damage, ensuring a smooth and efficient installation process.

Not only does a vacuum glass lifter offer cost savings, but it also optimizes time management on construction sites. The lifter’s ability to securely grip and transport glass panels eliminates the need for manual handling, which can be time-consuming and physically demanding. With a vacuum glass lifter, workers can quickly and effortlessly move glass panels from one location to another, reducing the time required for installation.

Additionally, the lifter’s precision and control allow for more accurate placement of glass panels, minimizing the need for adjustments or rework. This not only saves time but also ensures a higher quality of workmanship, enhancing the overall aesthetics and functionality of the building.

Another time-saving feature of a vacuum glass lifter is its versatility. It can be easily adjusted to accommodate different sizes and shapes of glass panels, making it suitable for a wide range of construction projects. Whether it’s installing windows, glass facades, or interior partitions, a vacuum glass lifter can handle the task efficiently and effectively.

In conclusion, a vacuum glass lifter is an essential tool for any construction site looking to optimize cost savings and time management. Its ability to securely grip and transport glass panels not only reduces the risk of accidents and injuries but also streamlines the installation process. By eliminating the need for manual handling and additional equipment, it offers significant cost savings. Moreover, its precision and versatility make it a valuable asset for any construction project. Investing in a vacuum glass lifter is a wise decision that can greatly enhance the efficiency and productivity of construction sites.