Benefits of Vacuum Glass Lifters for Handling Large Glass Panels

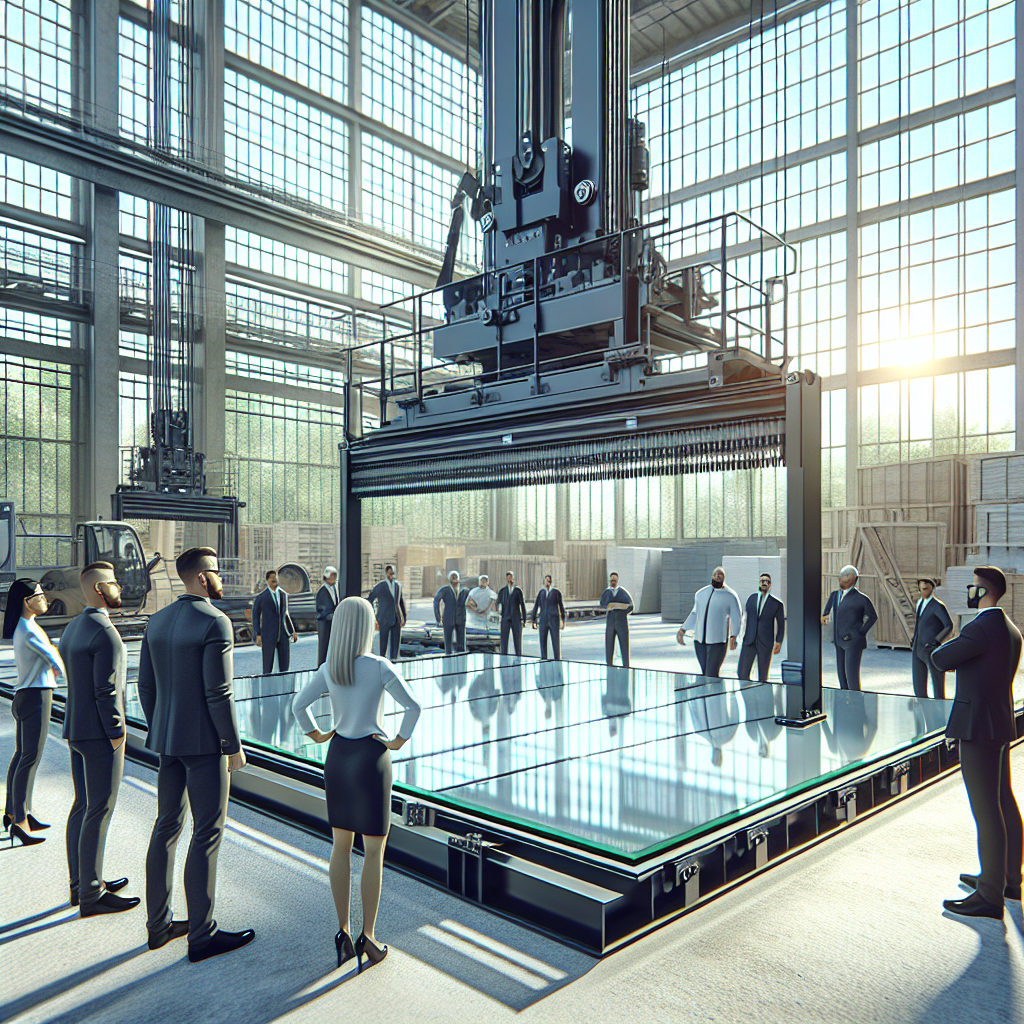

Vacuum Glass Lifters: The Safe Choice for Handling Large Glass Panels

When it comes to handling large glass panels, safety should always be the top priority. These panels are not only heavy but also fragile, making them prone to accidents and damage if not handled properly. That’s where vacuum glass lifters come in. These innovative devices are specifically designed to provide a safe and efficient solution for lifting and moving large glass panels.

One of the key benefits of vacuum glass lifters is their ability to securely grip the glass panels without causing any damage. Traditional lifting methods, such as using ropes or clamps, can often lead to scratches, cracks, or even shattered glass. Vacuum glass lifters, on the other hand, use suction cups to create a strong and reliable grip on the glass surface. This eliminates the risk of damage and ensures that the glass panels are lifted and moved safely.

Another advantage of vacuum glass lifters is their versatility. These devices can be used to handle glass panels of various sizes and shapes, including curved or irregularly shaped ones. The suction cups can be adjusted and positioned to match the specific dimensions of the glass, providing a secure grip regardless of its shape. This flexibility makes vacuum glass lifters a valuable tool for a wide range of industries, including construction, architecture, and manufacturing.

In addition to their versatility, vacuum glass lifters also offer efficiency and time-saving benefits. With traditional lifting methods, it often takes a team of workers to manually lift and move large glass panels. This not only requires more manpower but also increases the risk of accidents and injuries. Vacuum glass lifters, on the other hand, can be operated by a single person, reducing the need for additional labor and streamlining the handling process. This not only saves time but also improves productivity and reduces costs.

Furthermore, vacuum glass lifters are designed with safety features that further enhance their reliability. These features include audible and visual alarms that alert the operator in case of any issues, such as a loss of vacuum pressure. This ensures that any potential risks are immediately identified and addressed, preventing accidents and damage to the glass panels. Additionally, vacuum glass lifters are equipped with backup power systems, allowing them to safely lower the glass panels in the event of a power failure.

Lastly, vacuum glass lifters are designed with ergonomics in mind. They are equipped with adjustable handles and controls, allowing the operator to maintain a comfortable and safe working position. This reduces the risk of strain or injuries caused by repetitive lifting motions. The lightweight and compact design of vacuum glass lifters also make them easy to maneuver in tight spaces, further enhancing their usability and efficiency.

In conclusion, vacuum glass lifters are the safe choice for handling large glass panels. Their ability to securely grip the glass without causing damage, versatility in handling various sizes and shapes, efficiency in reducing labor and time, safety features, and ergonomic design make them an invaluable tool for any industry that deals with large glass panels. By investing in vacuum glass lifters, businesses can ensure the safety of their workers, protect their valuable glass panels, and improve overall productivity.

How Vacuum Glass Lifters Ensure Safety in Glass Panel Handling

Vacuum glass lifters have become the go-to choice for handling large glass panels in various industries. These innovative devices offer a safe and efficient solution for lifting and moving heavy glass panels, ensuring the safety of workers and preventing damage to the delicate material.

One of the key features of vacuum glass lifters is their ability to securely grip glass panels using suction cups. These suction cups are designed to create a vacuum seal with the glass surface, providing a strong and reliable hold. This eliminates the need for manual lifting and reduces the risk of accidents and injuries that can occur when handling heavy objects.

In addition to their secure grip, vacuum glass lifters are equipped with safety mechanisms that further enhance their reliability. These mechanisms include sensors that monitor the vacuum pressure and alert the operator if there is a loss of suction. This ensures that the glass panel remains securely attached to the lifter at all times, preventing any potential accidents or damage.

Furthermore, vacuum glass lifters are designed with ergonomic features that prioritize the safety and comfort of the operator. These features include adjustable handles and controls, allowing the operator to maintain a comfortable and natural posture while operating the lifter. This reduces the risk of strain or injury caused by awkward body positions or excessive physical exertion.

Another important aspect of vacuum glass lifters is their versatility. These devices can be used to handle glass panels of various sizes and shapes, making them suitable for a wide range of applications. Whether it’s lifting large windows, glass doors, or even curved glass panels, vacuum glass lifters can accommodate different requirements, ensuring that the handling process is safe and efficient.

Moreover, vacuum glass lifters are designed to minimize the risk of damage to the glass panels during the lifting and moving process. The suction cups are made from materials that are gentle on the glass surface, preventing scratches or cracks. Additionally, the lifters are equipped with features such as adjustable suction cup frames and tilt mechanisms, allowing for precise positioning and alignment of the glass panels. This ensures that the panels are handled with care and precision, reducing the likelihood of any damage occurring.

In conclusion, vacuum glass lifters offer a safe and efficient solution for handling large glass panels. Their secure grip, safety mechanisms, ergonomic features, and versatility make them the ideal choice for various industries. By using vacuum glass lifters, companies can ensure the safety of their workers, prevent damage to glass panels, and improve overall productivity. Whether it’s in construction, manufacturing, or any other industry that deals with large glass panels, vacuum glass lifters are the safe choice for handling these delicate and valuable materials.

Factors to Consider When Choosing Vacuum Glass Lifters for Large Glass Panels

Vacuum glass lifters are an essential tool for handling large glass panels safely and efficiently. When it comes to choosing the right vacuum glass lifter for your needs, there are several factors to consider. In this article, we will discuss these factors in detail to help you make an informed decision.

First and foremost, it is crucial to consider the weight capacity of the vacuum glass lifter. Large glass panels can be heavy, and you need a lifter that can handle the load. It is essential to choose a lifter with a weight capacity that exceeds the weight of the glass panels you will be working with. This ensures that the lifter can handle the load without any risk of accidents or damage to the glass.

Another factor to consider is the size and shape of the glass panels. Vacuum glass lifters come in various configurations to accommodate different panel sizes and shapes. It is important to choose a lifter that can securely grip the glass panels without any risk of slippage or instability. Some lifters come with adjustable suction cups or arms that can be customized to fit different panel sizes, providing added versatility.

The type of surface the glass panels will be lifted from is also an important consideration. Some vacuum glass lifters are designed specifically for smooth surfaces, such as glass or polished stone. These lifters use suction cups to create a vacuum seal, ensuring a secure grip on the glass. However, if you will be working with rough or uneven surfaces, such as concrete or wood, you will need a lifter that can handle these conditions. Look for lifters with specialized suction cups or additional features, such as rubber pads or gripping mechanisms, to ensure a secure grip on rough surfaces.

In addition to the weight capacity and surface compatibility, it is essential to consider the lifting mechanism of the vacuum glass lifter. Some lifters are manual, requiring physical effort to lift and maneuver the glass panels. These lifters are suitable for smaller projects or occasional use. However, for larger projects or frequent use, it is recommended to choose a lifter with a powered lifting mechanism. These lifters use electric or hydraulic systems to lift and lower the glass panels, reducing the strain on the operator and increasing productivity.

Safety is always a top priority when working with large glass panels. Therefore, it is crucial to choose a vacuum glass lifter that incorporates safety features. Look for lifters with audible and visual alarms that indicate when the vacuum seal is compromised or when the battery is running low. Additionally, some lifters come with backup systems, such as manual release valves or secondary vacuum pumps, to ensure the safe release of the glass panels in case of power failure.

Lastly, consider the overall quality and durability of the vacuum glass lifter. Look for lifters made from high-quality materials, such as stainless steel or aluminum, that can withstand the rigors of daily use. It is also important to choose a lifter from a reputable manufacturer that offers warranties and after-sales support.

In conclusion, choosing the right vacuum glass lifter for handling large glass panels requires careful consideration of several factors. These include weight capacity, size and shape compatibility, surface compatibility, lifting mechanism, safety features, and overall quality. By taking these factors into account, you can ensure that you make the safe and efficient choice for your glass handling needs.