Importance of Proper Training for Operating a Pneumatic Glass Lifter

Proper training is of utmost importance when it comes to operating a pneumatic glass lifter. This powerful piece of equipment is designed to lift and transport heavy glass panels, making it an essential tool in the construction and glazing industries. However, without the necessary training, using a pneumatic glass lifter can be dangerous and lead to accidents and injuries.

One of the main reasons why proper training is crucial is because a pneumatic glass lifter requires a certain level of skill and knowledge to operate safely. These lifters are equipped with various controls and mechanisms that need to be understood and used correctly to ensure smooth and secure lifting. Without proper training, operators may not be aware of the correct procedures for operating the lifter, which can result in accidents and damage to the glass panels.

Additionally, training helps operators understand the limitations and capabilities of a pneumatic glass lifter. These lifters are designed to handle specific weight capacities and sizes of glass panels. By undergoing training, operators learn how to assess the weight and dimensions of the glass panels and determine whether the lifter is suitable for the task at hand. This knowledge is crucial in preventing overloading the lifter, which can lead to equipment failure and accidents.

Furthermore, training provides operators with the necessary knowledge to identify potential hazards and risks associated with using a pneumatic glass lifter. They learn how to inspect the lifter for any signs of damage or malfunction before each use, ensuring that it is in proper working condition. Operators also learn about the importance of maintaining a clean and clutter-free work area to prevent accidents caused by tripping or slipping.

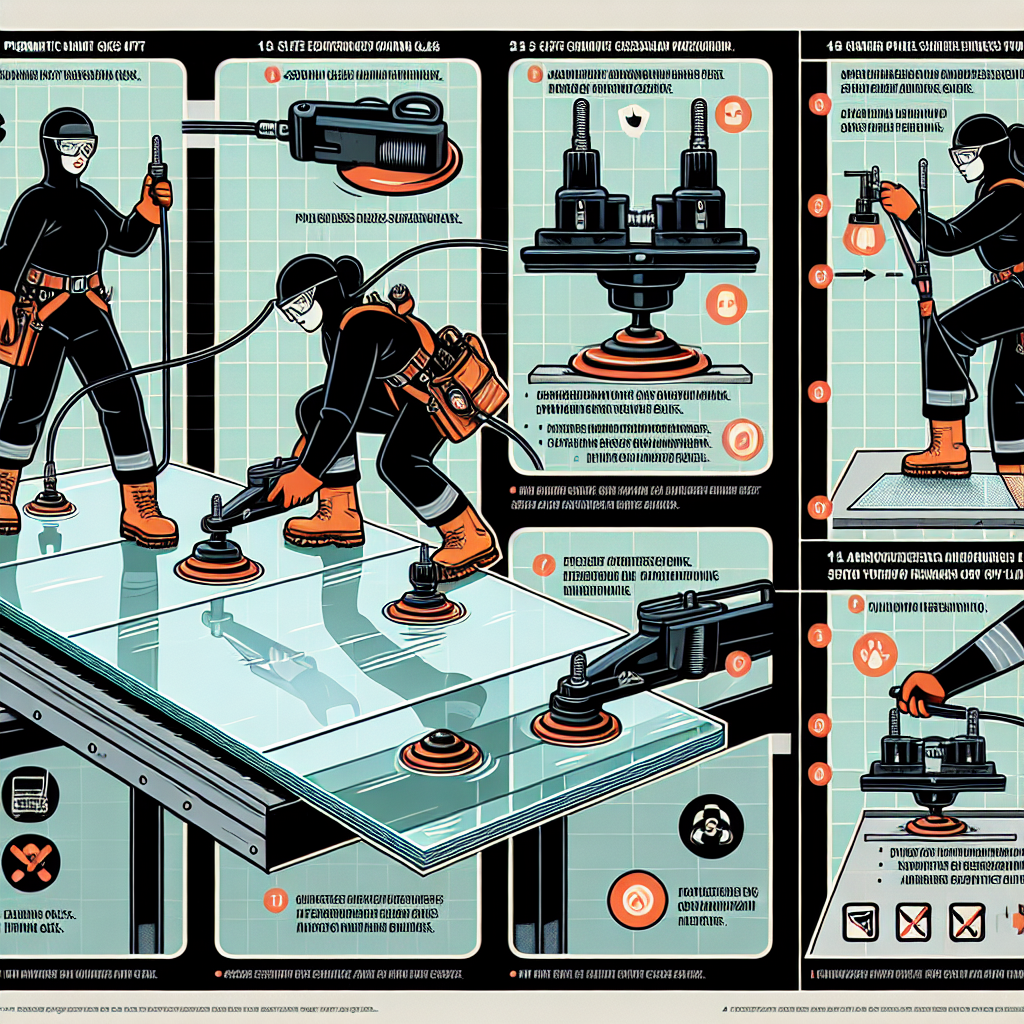

Another important aspect of training is teaching operators the correct lifting techniques. Using a pneumatic glass lifter requires precision and careful maneuvering to ensure that the glass panels are lifted and transported safely. Operators learn how to position the lifter correctly, attach it securely to the glass panels, and operate the controls smoothly. These techniques not only maximize safety but also help prevent damage to the glass panels.

In addition to safety considerations, proper training also helps operators understand the importance of regular maintenance and inspections of the pneumatic glass lifter. They learn how to perform routine maintenance tasks, such as lubricating moving parts and checking for leaks in the pneumatic system. By following these maintenance procedures, operators can ensure that the lifter remains in optimal condition, reducing the risk of accidents and breakdowns.

In conclusion, proper training is essential for anyone operating a pneumatic glass lifter. It provides operators with the necessary skills and knowledge to operate the lifter safely and efficiently. By understanding the correct procedures, limitations, and potential hazards associated with using a pneumatic glass lifter, operators can maximize safety and prevent accidents and injuries. Investing in training not only protects the well-being of the operators but also helps maintain the longevity and reliability of the equipment.

Essential Safety Precautions to Follow When Using a Pneumatic Glass Lifter

A pneumatic glass lifter is a powerful tool that can greatly assist in lifting and moving heavy glass panels. However, it is important to remember that safety should always be the top priority when using this equipment. By following a few essential safety precautions, you can maximize safety and minimize the risk of accidents or injuries.

First and foremost, it is crucial to ensure that the pneumatic glass lifter is in good working condition before use. This means regularly inspecting the equipment for any signs of damage or wear and tear. Check the hoses, valves, and connectors for leaks or cracks, and make sure that all the components are securely fastened. If any issues are detected, the lifter should be immediately taken out of service and repaired by a qualified technician.

Another important safety precaution is to always wear the appropriate personal protective equipment (PPE) when operating a pneumatic glass lifter. This includes safety glasses or goggles to protect the eyes from flying debris, gloves to provide a secure grip on the lifter controls, and steel-toed boots to protect the feet from potential hazards. Additionally, it is recommended to wear a hard hat to protect the head in case of falling objects.

When using a pneumatic glass lifter, it is essential to have a clear understanding of the weight capacity of the lifter and to never exceed this limit. Overloading the lifter can cause it to become unstable and increase the risk of accidents. Always check the weight of the glass panels before attempting to lift them and ensure that the lifter is rated to handle the load.

Proper positioning of the lifter is also crucial for safety. Before lifting a glass panel, make sure that the lifter is on a stable and level surface. If necessary, use leveling devices or shims to ensure stability. It is also important to position the lifter close to the glass panel to minimize the risk of tipping or tilting during the lifting process.

During the lifting operation, it is important to maintain clear communication with other workers involved in the task. Establish clear hand signals or verbal cues to ensure that everyone is on the same page and to avoid any misunderstandings or accidents. Additionally, it is important to never leave the lifter unattended while the glass panel is suspended in the air. Always have at least one person monitoring the lifter and the glass panel to ensure stability and safety.

Finally, it is crucial to follow proper lifting techniques when using a pneumatic glass lifter. This includes using slow and controlled movements to lift and lower the glass panel, avoiding sudden jerks or movements that could cause the panel to swing or fall. It is also important to keep the lifter and the glass panel away from any obstacles or obstructions that could interfere with the lifting operation.

In conclusion, maximizing safety when using a pneumatic glass lifter requires following essential safety precautions. Regularly inspecting the equipment, wearing appropriate PPE, understanding weight capacity, positioning the lifter correctly, maintaining clear communication, and following proper lifting techniques are all crucial steps to ensure a safe and accident-free operation. By prioritizing safety, you can confidently and efficiently use a pneumatic glass lifter to handle heavy glass panels.

Maintenance and Inspection Tips to Ensure Safe and Efficient Operation of a Pneumatic Glass Lifter

A pneumatic glass lifter is a valuable tool that can greatly enhance safety and efficiency when handling glass. However, like any piece of equipment, it requires regular maintenance and inspection to ensure safe and efficient operation. In this section, we will discuss some important maintenance and inspection tips that will help you maximize safety with your pneumatic glass lifter.

First and foremost, it is crucial to regularly inspect the lifter for any signs of wear or damage. This includes checking the hoses, fittings, and valves for leaks or cracks. Any damaged components should be replaced immediately to prevent accidents or malfunctions. Additionally, it is important to inspect the lifting pads for any signs of wear or deterioration. Worn or damaged pads can compromise the lifter’s ability to securely grip the glass, increasing the risk of accidents. Therefore, it is essential to replace any worn or damaged pads promptly.

In addition to regular inspections, proper lubrication is essential for the smooth operation of a pneumatic glass lifter. Lubricate all moving parts, such as the pistons and cylinders, according to the manufacturer’s recommendations. This will help prevent friction and ensure that the lifter operates efficiently. It is also important to regularly clean the lifter to remove any dirt or debris that may accumulate over time. This will help prevent clogs and ensure that the lifter functions properly.

Another important aspect of maintaining a pneumatic glass lifter is to regularly check the air pressure. The lifter relies on compressed air to operate, so it is crucial to ensure that the air pressure is within the recommended range. Use a pressure gauge to check the air pressure regularly and adjust it if necessary. Operating the lifter with insufficient air pressure can lead to decreased lifting capacity and compromised safety. Therefore, it is important to monitor and maintain the proper air pressure at all times.

Furthermore, it is essential to provide proper training to all operators of the pneumatic glass lifter. They should be familiar with the lifter’s operation and safety features, as well as any specific guidelines or precautions provided by the manufacturer. Proper training will help ensure that the lifter is used correctly and safely, minimizing the risk of accidents or injuries.

Lastly, it is important to keep a record of all maintenance and inspections performed on the pneumatic glass lifter. This will help track the lifter’s performance over time and identify any recurring issues or patterns. It will also serve as a valuable reference for future maintenance and inspections. Additionally, keeping a record of maintenance and inspections can be beneficial for compliance with safety regulations and standards.

In conclusion, regular maintenance and inspection are crucial for maximizing safety and efficiency with a pneumatic glass lifter. By regularly inspecting the lifter, lubricating moving parts, checking air pressure, providing proper training, and keeping a record of maintenance and inspections, you can ensure that your pneumatic glass lifter operates safely and effectively. Remember, safety should always be the top priority when using any equipment, and a well-maintained pneumatic glass lifter is no exception.