The Benefits of Using Vacuum Glass Lifters in Construction Projects

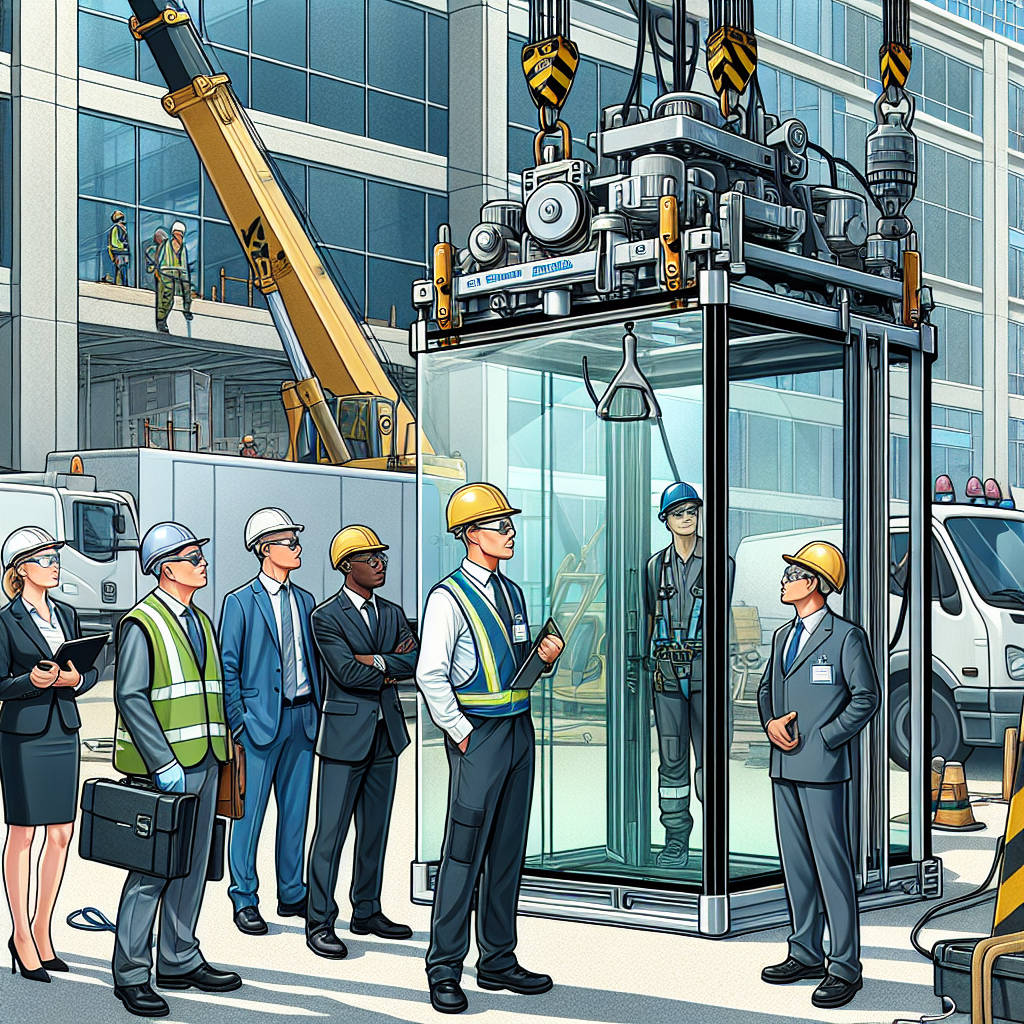

Vacuum glass lifters have become an essential tool in construction projects, revolutionizing the way glass panels are handled and installed. These innovative devices offer numerous benefits that not only improve safety but also enhance efficiency on the job site.

One of the primary advantages of using vacuum glass lifters is the increased safety they provide. Traditional methods of lifting and installing glass panels often involve manual labor, which can be hazardous and prone to accidents. With vacuum glass lifters, the risk of injuries is significantly reduced. These devices utilize suction cups that securely grip the glass, eliminating the need for workers to physically handle the panels. This minimizes the chances of glass breakage and the potential for cuts or other injuries.

Furthermore, vacuum glass lifters are designed to distribute the weight of the glass evenly, preventing any undue stress on the panels. This ensures that the glass remains intact during the lifting and installation process, reducing the risk of accidents caused by glass breakage. The stability provided by these lifters also allows for precise positioning of the glass, ensuring a perfect fit and minimizing the need for adjustments or rework.

In addition to improving safety, vacuum glass lifters also enhance efficiency on construction projects. These devices are equipped with powerful suction systems that can lift and transport heavy glass panels with ease. This eliminates the need for manual lifting, which can be time-consuming and physically demanding. With vacuum glass lifters, workers can quickly and effortlessly move glass panels from one location to another, saving valuable time and energy.

Moreover, vacuum glass lifters are versatile tools that can be used in various construction scenarios. Whether it’s installing windows in high-rise buildings or handling large glass panels for interior partitions, these lifters can adapt to different project requirements. They can be easily adjusted to accommodate different sizes and shapes of glass, making them suitable for a wide range of applications. This versatility allows construction teams to streamline their operations and complete projects more efficiently.

Another advantage of using vacuum glass lifters is the reduced risk of damage to the glass panels. Traditional lifting methods often involve the use of clamps or hooks, which can cause scratches or other forms of damage to the glass surface. Vacuum glass lifters, on the other hand, use suction cups that provide a secure grip without causing any harm to the glass. This ensures that the panels remain in pristine condition throughout the installation process, eliminating the need for costly repairs or replacements.

In conclusion, vacuum glass lifters offer numerous benefits that significantly improve safety and efficiency on construction projects. These devices eliminate the need for manual lifting, reducing the risk of injuries and glass breakage. They also enhance efficiency by allowing for quick and precise positioning of glass panels. With their versatility and ability to prevent damage to the glass, vacuum glass lifters have become an indispensable tool in the construction industry. By investing in these innovative devices, construction teams can ensure a safer work environment and complete projects more efficiently.

How Vacuum Glass Lifters Enhance Workplace Safety and Reduce Accidents

Vacuum glass lifters have become an essential tool in the construction and manufacturing industries, as they offer a safe and efficient way to handle heavy glass panels. These innovative devices have revolutionized the way glass is handled, significantly reducing the risk of accidents and injuries in the workplace.

One of the primary benefits of vacuum glass lifters is their ability to enhance workplace safety. Traditional methods of lifting and moving glass panels involved manual labor, which often led to accidents and injuries. Workers had to rely on their physical strength to lift and carry heavy glass, which put them at risk of strains, sprains, and even fractures.

With vacuum glass lifters, the need for manual lifting is eliminated. These devices use suction cups to securely grip the glass panels, allowing workers to move them effortlessly. By removing the physical strain associated with lifting heavy objects, vacuum glass lifters significantly reduce the risk of injuries in the workplace.

Furthermore, vacuum glass lifters are designed with safety features that further enhance workplace safety. These features include audible and visual alarms that alert workers if the vacuum seal is compromised. This ensures that workers are aware of any potential risks and can take immediate action to prevent accidents.

In addition to improving safety, vacuum glass lifters also enhance efficiency on the job. Traditional methods of handling glass panels were time-consuming and required multiple workers to complete a task. This not only slowed down the workflow but also increased labor costs.

With vacuum glass lifters, a single worker can easily handle and maneuver glass panels, reducing the need for additional manpower. This allows for faster completion of tasks and increased productivity. Moreover, the precision and control offered by vacuum glass lifters ensure that glass panels are positioned accurately, saving time and effort in readjustments.

Another advantage of vacuum glass lifters is their versatility. These devices can be used to handle a wide range of glass panel sizes and shapes, making them suitable for various applications. Whether it’s installing windows in a high-rise building or handling delicate glass artwork, vacuum glass lifters provide a safe and efficient solution.

It is worth noting that vacuum glass lifters are not only beneficial for workers but also for the glass panels themselves. The suction cups used in these devices distribute the weight evenly, reducing the risk of damage to the glass. This is particularly important when handling expensive or fragile glass panels, as any damage can result in significant financial losses.

In conclusion, vacuum glass lifters have revolutionized the way glass is handled in the construction and manufacturing industries. By eliminating the need for manual lifting and providing enhanced safety features, these devices significantly reduce the risk of accidents and injuries in the workplace. Moreover, their efficiency and versatility make them a valuable tool for improving productivity and handling various glass panel applications. With vacuum glass lifters, workers can now handle heavy glass panels with ease, ensuring both their safety and the integrity of the glass.

Increasing Efficiency and Productivity with Vacuum Glass Lifters in Glass Installation

Vacuum glass lifters have revolutionized the glass installation industry, providing a safer and more efficient way to handle and transport glass panels. These innovative devices have become an essential tool for glaziers and construction workers, allowing them to complete their tasks with greater ease and speed.

One of the key benefits of using vacuum glass lifters is the significant increase in efficiency and productivity. Traditional methods of glass installation often involve multiple workers manually lifting and carrying heavy glass panels, which can be time-consuming and physically demanding. With vacuum glass lifters, a single operator can easily handle and transport glass panels, reducing the need for additional manpower and streamlining the installation process.

The efficiency of vacuum glass lifters is further enhanced by their ability to lift and position glass panels with precision. These devices are equipped with powerful suction cups that create a strong vacuum seal, securely holding the glass in place. This eliminates the risk of glass panels slipping or falling during installation, reducing the likelihood of accidents and damage to the glass. The precise control offered by vacuum glass lifters allows for accurate positioning of the glass panels, ensuring a perfect fit and alignment.

In addition to improving efficiency, vacuum glass lifters also contribute to a safer working environment. The manual lifting and carrying of heavy glass panels can pose a significant risk of injury to workers. Back strains, muscle sprains, and other musculoskeletal injuries are common in the glass installation industry. By eliminating the need for manual lifting, vacuum glass lifters greatly reduce the risk of these injuries, protecting the health and well-being of workers.

Furthermore, the use of vacuum glass lifters minimizes the potential for accidents and damage to the glass panels. The secure vacuum seal created by the suction cups ensures that the glass remains firmly in place during transportation and installation. This eliminates the risk of glass panels slipping or falling, which can cause injuries to workers and result in costly damage to the glass. The enhanced safety provided by vacuum glass lifters not only protects workers but also reduces the financial burden associated with accidents and repairs.

Another advantage of vacuum glass lifters is their versatility. These devices can be used for a wide range of glass installation tasks, including lifting, tilting, rotating, and transporting glass panels of various sizes and shapes. This versatility allows glaziers and construction workers to handle different types of glass with ease, making vacuum glass lifters a valuable investment for any glass installation project.

In conclusion, vacuum glass lifters have proven to be a game-changer in the glass installation industry. By increasing efficiency and productivity, improving safety, and offering versatility, these devices have become an indispensable tool for glaziers and construction workers. The use of vacuum glass lifters not only streamlines the installation process but also protects the well-being of workers and minimizes the risk of accidents and damage to glass panels. With their numerous benefits, vacuum glass lifters are undoubtedly a valuable asset for any glass installation project, ensuring a safer and more efficient working environment.