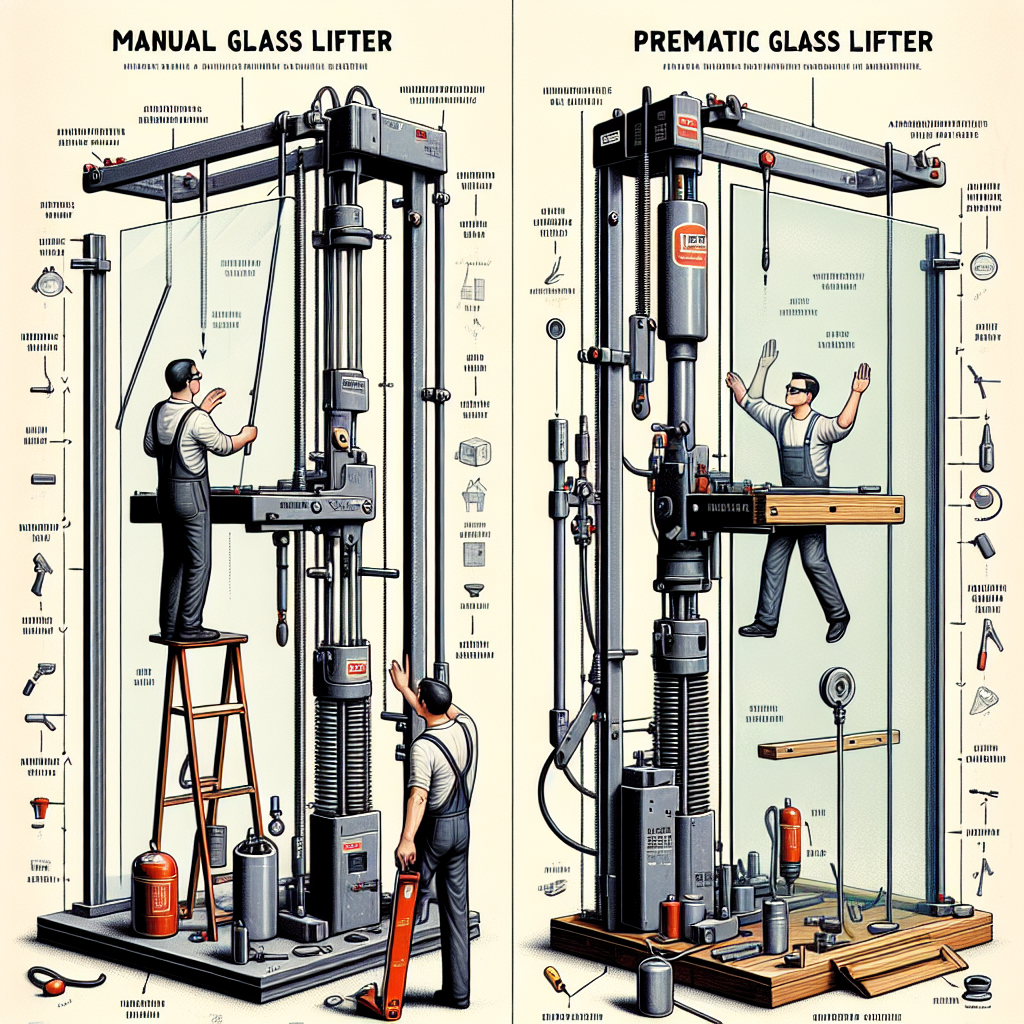

Pros and Cons of Manual Glass Lifters

When it comes to choosing a glass lifter, there are several factors to consider. One of the most important decisions you will need to make is whether to opt for a manual glass lifter or a pneumatic glass lifter. Both options have their own set of pros and cons, and understanding these can help you make an informed decision.

Let’s start by looking at the pros of manual glass lifters. One of the biggest advantages of manual glass lifters is their simplicity. These lifters are typically operated by hand, making them easy to use and maintain. They do not require any external power source, which means you can use them anywhere, even in remote locations where electricity may not be readily available.

Another advantage of manual glass lifters is their affordability. Compared to pneumatic glass lifters, manual lifters are generally more budget-friendly. This makes them a popular choice for small businesses or individuals who may not have a large budget to invest in equipment.

Manual glass lifters also offer a high level of control. With a manual lifter, you have complete control over the lifting and lowering process. This can be particularly beneficial when working with delicate or fragile glass, as you can adjust the lifting speed and pressure to ensure the glass is handled with care.

However, manual glass lifters do have their drawbacks. One of the main disadvantages is the physical effort required to operate them. Lifting heavy glass panels manually can be tiring and may pose a risk of injury, especially if proper lifting techniques are not followed. This can be a significant concern if you frequently need to lift large or heavy glass panels.

Another limitation of manual glass lifters is their lifting capacity. Manual lifters are generally designed for lighter loads, and may not be suitable for lifting extremely heavy or oversized glass panels. If you regularly work with large or heavy glass, a manual lifter may not be the most efficient option for you.

In contrast, pneumatic glass lifters offer several advantages over their manual counterparts. One of the biggest benefits is their lifting capacity. Pneumatic lifters are capable of lifting much heavier loads, making them ideal for handling large glass panels or other heavy materials.

Pneumatic glass lifters also offer a higher level of safety. These lifters are typically equipped with safety features such as vacuum sensors and alarms, which help prevent accidents and ensure the glass is securely held during the lifting process. This can provide peace of mind, especially when working with valuable or fragile glass.

However, pneumatic glass lifters do have some drawbacks. One of the main disadvantages is their reliance on an external power source. Pneumatic lifters require a compressed air supply to operate, which means you will need access to a suitable air compressor. This can limit their portability and may not be feasible in certain locations.

Another limitation of pneumatic glass lifters is their complexity. These lifters often require more maintenance and may be more prone to mechanical issues compared to manual lifters. This can result in higher maintenance costs and downtime if repairs are needed.

In conclusion, choosing between a manual and pneumatic glass lifter depends on your specific needs and requirements. Manual lifters offer simplicity, affordability, and control, but may not be suitable for heavy or oversized glass panels. Pneumatic lifters, on the other hand, offer higher lifting capacity and safety features, but require an external power source and may be more complex to maintain. Consider these pros and cons carefully to make the best decision for your glass lifting needs.

Advantages and Disadvantages of Pneumatic Glass Lifters

Pneumatic glass lifters have become increasingly popular in the construction and manufacturing industries due to their ability to lift and transport heavy glass panels with ease. However, before investing in a pneumatic glass lifter, it is important to consider the advantages and disadvantages of this type of equipment.

One of the main advantages of pneumatic glass lifters is their ability to lift heavy glass panels without requiring manual effort. This can significantly reduce the risk of injury to workers and increase productivity on the job site. Pneumatic glass lifters are equipped with powerful suction cups that create a vacuum seal on the glass surface, allowing the lifter to securely grip and lift the glass panel. This eliminates the need for workers to manually lift and carry heavy glass, which can be physically demanding and potentially dangerous.

Another advantage of pneumatic glass lifters is their versatility. These lifters can be used to lift glass panels of various sizes and shapes, making them suitable for a wide range of applications. Whether you need to lift small windows or large glass sheets, a pneumatic glass lifter can handle the job. Additionally, some models of pneumatic glass lifters are equipped with adjustable suction cups, allowing for precise positioning of the glass panel.

In addition to their advantages, pneumatic glass lifters also have some disadvantages that should be considered. One of the main disadvantages is the need for a power source. Pneumatic glass lifters require a compressed air source to operate, which means that they cannot be used in areas where there is no access to compressed air. This can limit their use in certain job sites or locations.

Another disadvantage of pneumatic glass lifters is their cost. Compared to manual glass lifters, pneumatic lifters tend to be more expensive. This is due to the complex mechanisms and components required to create the vacuum seal and lift the glass panel. However, it is important to consider the long-term benefits and increased productivity that pneumatic glass lifters can provide, which may outweigh the initial investment.

Furthermore, pneumatic glass lifters require regular maintenance and inspection to ensure their proper functioning. The suction cups and seals need to be checked and replaced if necessary to maintain a secure grip on the glass panel. Additionally, the compressed air system needs to be properly maintained to prevent any leaks or malfunctions.

In conclusion, pneumatic glass lifters offer several advantages, including the ability to lift heavy glass panels without manual effort and their versatility in handling different sizes and shapes of glass. However, they also have some disadvantages, such as the need for a power source and the higher cost compared to manual lifters. It is important to carefully consider these factors and assess the specific needs of your job site before deciding whether a pneumatic glass lifter is the right choice for you.

Factors to Consider When Choosing Between Manual and Pneumatic Glass Lifters

When it comes to choosing between a manual and pneumatic glass lifter, there are several factors that need to be considered. Both options have their own advantages and disadvantages, and it is important to carefully evaluate these factors before making a decision.

One of the main factors to consider is the weight of the glass that needs to be lifted. Manual glass lifters are typically designed to handle lighter loads, while pneumatic glass lifters are capable of lifting heavier loads. If you are working with large, heavy pieces of glass, a pneumatic glass lifter may be the better option as it can provide the necessary lifting power.

Another factor to consider is the level of control that you require. Manual glass lifters are operated by hand, allowing for precise control over the lifting process. This can be particularly important when working with delicate or fragile glass. On the other hand, pneumatic glass lifters are powered by compressed air and offer a more automated lifting process. While this can be convenient, it may not provide the same level of control as a manual lifter.

The type of work environment should also be taken into account. Manual glass lifters are generally more portable and easier to maneuver in tight spaces. They do not require a power source, making them suitable for outdoor or remote locations. Pneumatic glass lifters, on the other hand, require a compressed air source and may be less portable. They are typically used in more controlled environments such as factories or warehouses.

Cost is another important factor to consider. Manual glass lifters are generally less expensive than pneumatic glass lifters. They do not require any additional equipment or power source, making them a more cost-effective option. Pneumatic glass lifters, on the other hand, require a compressed air source and may require additional equipment such as hoses and fittings. This can significantly increase the overall cost.

Maintenance and durability should also be taken into consideration. Manual glass lifters are generally simpler in design and require less maintenance. They are less prone to mechanical failures and can last for many years with proper care. Pneumatic glass lifters, on the other hand, require regular maintenance to ensure proper functioning. They may also be more prone to mechanical failures, which can result in costly repairs.

Lastly, it is important to consider the level of training and expertise required to operate the glass lifter. Manual glass lifters are generally easier to operate and require less training. They can be used by individuals with minimal experience. Pneumatic glass lifters, on the other hand, may require more training and expertise to operate safely and efficiently.

In conclusion, choosing between a manual and pneumatic glass lifter requires careful consideration of several factors. The weight of the glass, level of control required, work environment, cost, maintenance, and training are all important factors to evaluate. By carefully considering these factors, you can make an informed decision and choose the glass lifter that best suits your needs.