Proper Handling Techniques for Vacuum Glass Lifters

Proper Handling Techniques for Vacuum Glass Lifters

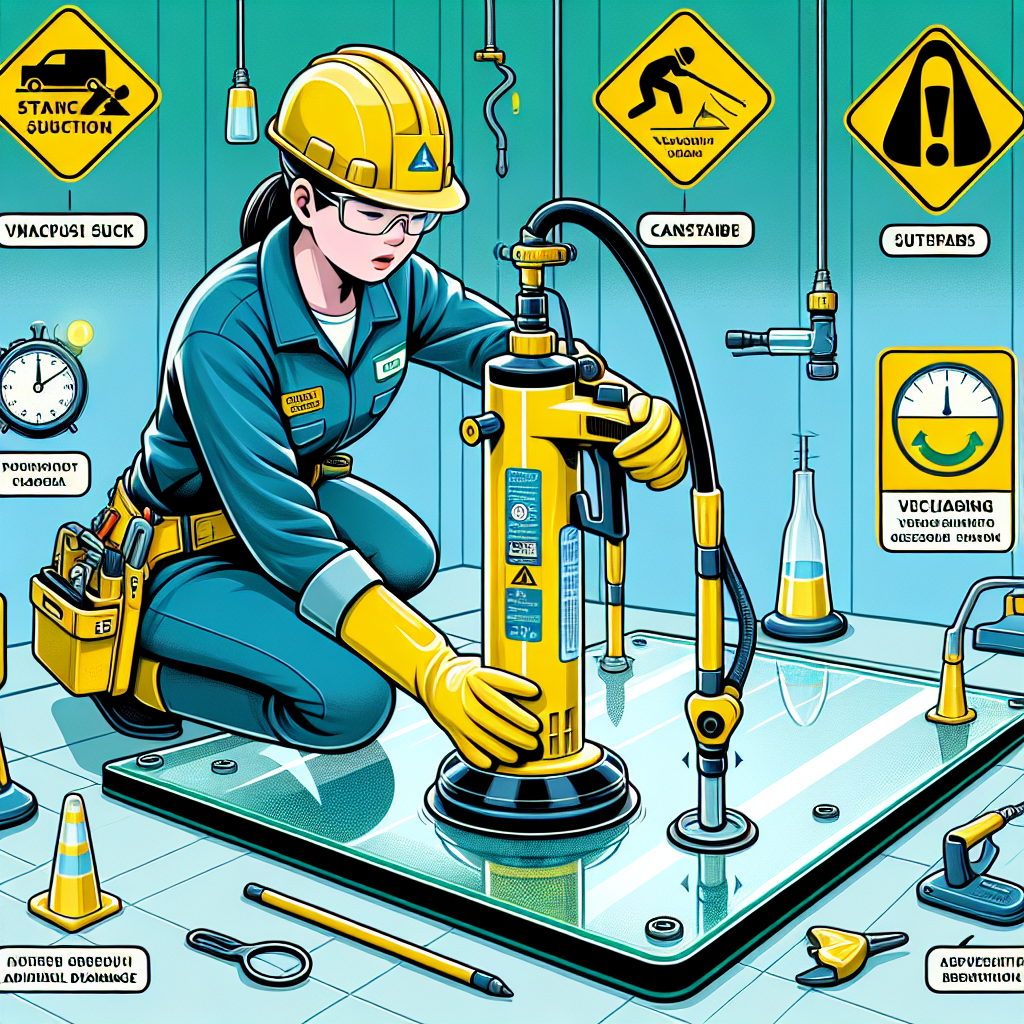

Vacuum glass lifters are an essential tool for handling large glass panels, windows, and other fragile materials. These devices use suction cups to create a vacuum seal, allowing for safe and efficient lifting and moving. However, if not used correctly, vacuum glass lifters can cause damage to the glass or even pose a safety risk. In this article, we will discuss some important handling techniques to help you avoid damage and ensure the safe use of a vacuum glass lifter.

First and foremost, it is crucial to inspect the glass lifter before each use. Check for any signs of wear or damage, such as cracks in the suction cups or leaks in the vacuum system. If any issues are detected, the lifter should be taken out of service and repaired or replaced as necessary. Regular maintenance and inspection are essential to ensure the lifter’s reliability and prevent accidents.

When using a vacuum glass lifter, it is important to ensure that the surface of the glass is clean and free from any debris or contaminants. Even small particles can compromise the vacuum seal and increase the risk of the glass slipping or breaking during lifting. Before attaching the lifter to the glass, thoroughly clean the surface using an appropriate glass cleaner and a lint-free cloth.

Proper positioning of the suction cups is another critical aspect of safe glass lifting. The cups should be placed evenly across the glass panel, ensuring that they are firmly attached and creating a secure vacuum seal. It is recommended to use a lifter with multiple suction cups to distribute the weight evenly and minimize the risk of stress concentration on a single point.

When lifting the glass, it is important to do so slowly and steadily. Jerky or sudden movements can cause the glass to shift or break, especially if it is large or heavy. Use the lifter’s controls to raise or lower the glass smoothly, keeping a close eye on its stability throughout the process. If any signs of instability or slippage are observed, stop immediately and reassess the lifting technique.

During transportation, it is crucial to secure the glass properly to prevent it from shifting or falling. If the glass is being transported horizontally, use straps or other restraints to hold it in place. If it needs to be transported vertically, ensure that it is properly supported and that the lifter’s suction cups remain securely attached. Always follow the manufacturer’s guidelines for the maximum weight and size limits of the lifter to avoid overloading it.

Finally, when lowering the glass, it is important to do so gently and with caution. Lower it onto a stable and level surface, ensuring that there are no obstructions or uneven terrain that could cause the glass to tip or break. Once the glass is safely on the ground, release the vacuum seal gradually and carefully remove the lifter from the glass.

In conclusion, proper handling techniques are essential for the safe and effective use of a vacuum glass lifter. Regular inspection and maintenance, along with a clean and debris-free glass surface, are crucial for preventing damage and accidents. Proper positioning of the suction cups, slow and steady lifting, secure transportation, and gentle lowering are all important steps to ensure the safe handling of glass panels. By following these guidelines, you can avoid damage and ensure the longevity of your vacuum glass lifter.

Essential Maintenance Tips for Vacuum Glass Lifters

Vacuum glass lifters are essential tools for handling and moving glass panels safely and efficiently. They use suction cups to create a vacuum seal, allowing the lifter to securely grip the glass. However, like any tool, vacuum glass lifters require regular maintenance to ensure they continue to function properly and avoid causing damage to the glass.

One of the most important maintenance tips for vacuum glass lifters is to regularly inspect the suction cups. Over time, the suction cups can become worn or damaged, which can compromise their ability to create a strong vacuum seal. Inspecting the suction cups for any signs of wear or damage, such as cracks or tears, is crucial. If any issues are found, the suction cups should be replaced immediately to prevent any potential damage to the glass.

In addition to inspecting the suction cups, it is also important to clean them regularly. Dust, dirt, and debris can accumulate on the suction cups, which can affect their ability to create a strong seal. Cleaning the suction cups with a mild detergent and warm water can help remove any buildup and ensure they are clean and ready for use. It is important to avoid using harsh chemicals or abrasive materials, as these can damage the suction cups.

Another essential maintenance tip for vacuum glass lifters is to check the vacuum pump regularly. The vacuum pump is responsible for creating the suction that holds the glass in place. If the vacuum pump is not functioning properly, it can result in a weak vacuum seal or no seal at all, which can lead to the glass slipping or falling. Checking the vacuum pump for any signs of damage or malfunction, such as unusual noises or a decrease in suction power, is crucial. If any issues are detected, the vacuum pump should be repaired or replaced as soon as possible to prevent any potential accidents or damage.

Furthermore, it is important to store the vacuum glass lifter properly when not in use. Storing the lifter in a clean and dry environment can help prevent any damage to the suction cups or other components. It is also important to avoid placing heavy objects on top of the lifter, as this can cause unnecessary pressure and potentially damage the lifter.

Lastly, regular training and education on the proper use of vacuum glass lifters is essential to avoid damage. Operators should be trained on how to properly attach and detach the lifter from the glass, as well as how to safely maneuver and transport the glass. This can help prevent any mishaps or accidents that could result in damage to the glass or injury to the operator.

In conclusion, regular maintenance is crucial for ensuring the safe and effective use of vacuum glass lifters. Inspecting and cleaning the suction cups, checking the vacuum pump, proper storage, and regular training are all essential maintenance tips to avoid damage. By following these tips, users can ensure that their vacuum glass lifters continue to function properly and safely handle glass panels without causing any damage.

Safety Precautions to Prevent Damage when Using Vacuum Glass Lifters

Vacuum glass lifters are a valuable tool for handling glass panels, windows, and other fragile materials. They provide a secure grip and make it easier to transport heavy and delicate items. However, it is important to use these lifters with caution to avoid any potential damage. In this article, we will discuss some safety precautions that can help prevent damage when using a vacuum glass lifter.

First and foremost, it is crucial to inspect the lifter before each use. Check for any signs of wear and tear, such as cracks or leaks in the suction cups or hoses. If you notice any damage, do not use the lifter and have it repaired or replaced immediately. Using a faulty lifter can lead to accidents and damage to the glass or other materials being lifted.

Before attaching the lifter to the glass, ensure that the surface is clean and free from any debris or contaminants. Even small particles can affect the suction and compromise the lifter’s grip. Use a soft cloth or brush to remove any dirt or dust from the glass surface. This simple step can significantly reduce the risk of damage during lifting.

When attaching the lifter to the glass, make sure to position it correctly. The suction cups should be placed evenly and firmly on the glass surface. Avoid placing them on any edges or corners, as these areas are more prone to cracking or chipping. Additionally, ensure that the lifter is securely attached and that the vacuum is properly activated before lifting the glass. This will provide a stable grip and minimize the chances of the glass slipping or falling.

While lifting the glass, it is important to maintain a steady and controlled movement. Sudden jerks or movements can cause the glass to shift or break. Use slow and smooth motions to transport the glass to its desired location. If you need to change the direction or angle of the glass, do so gradually and carefully. This will help prevent any unnecessary stress on the glass and reduce the risk of damage.

Another crucial safety precaution is to never exceed the lifter’s weight capacity. Each vacuum glass lifter has a specified weight limit that should not be exceeded. Overloading the lifter can lead to a loss of suction and result in the glass slipping or falling. Always check the lifter’s specifications and ensure that the weight of the glass being lifted is within the recommended range.

Lastly, it is important to have a clear and unobstructed path when moving the glass. Make sure there are no obstacles or hazards in the way that could cause the glass to collide with other objects. Clear the area of any debris or clutter to ensure a smooth and safe movement. Additionally, if you are working with a team, establish clear communication and coordination to avoid any accidents or mishaps.

In conclusion, using a vacuum glass lifter can greatly facilitate the handling of fragile materials like glass. However, it is essential to follow safety precautions to prevent any damage. Inspect the lifter before each use, clean the glass surface, position the lifter correctly, maintain steady movements, avoid overloading, and ensure a clear path. By adhering to these precautions, you can safely and effectively use a vacuum glass lifter without causing any damage.