Safety Features of Pneumatic Glass Lifters

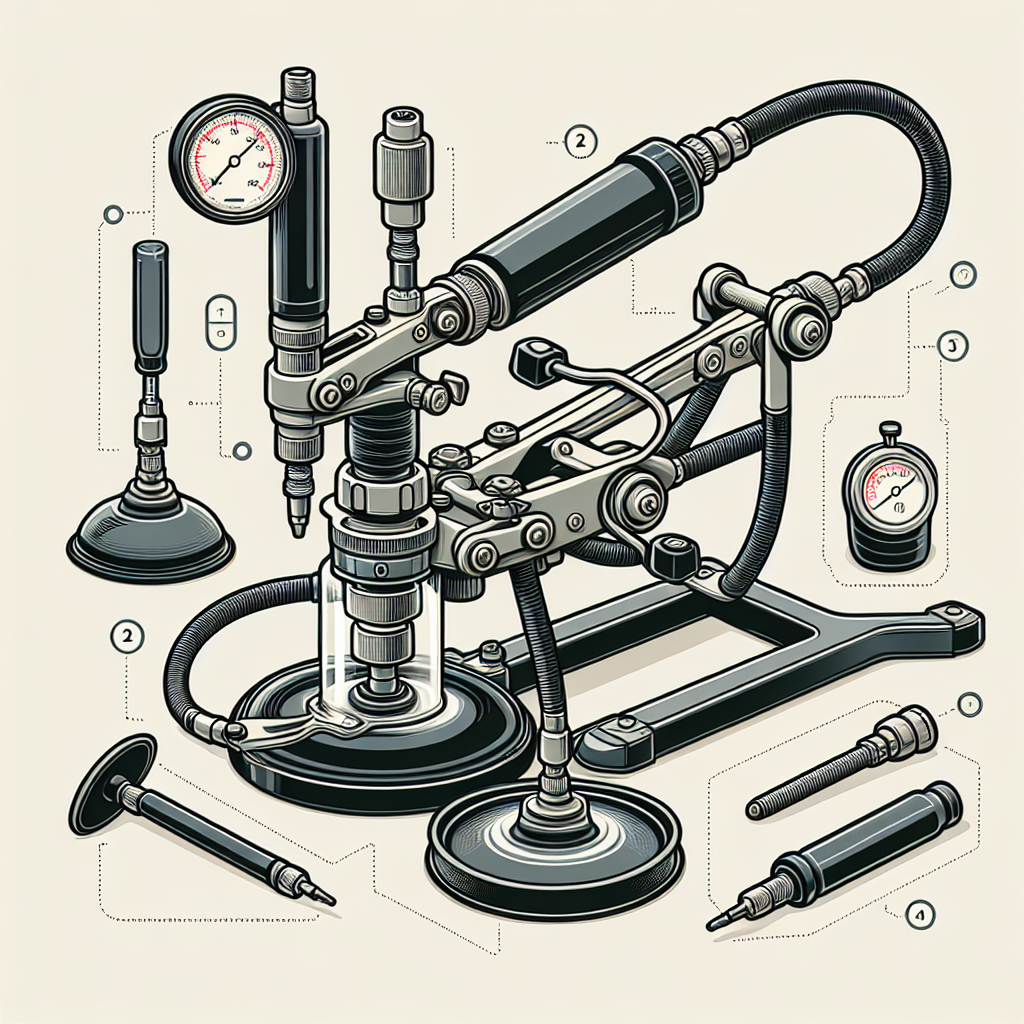

Pneumatic glass lifters are essential tools for safely and efficiently handling glass panels in various industries, including construction, manufacturing, and transportation. These devices use compressed air to create a vacuum seal, allowing them to lift and move heavy glass with ease. When choosing a pneumatic glass lifter, it is crucial to consider the safety features it offers to ensure the well-being of workers and the protection of valuable glass materials.

One of the most important safety features to look for in a pneumatic glass lifter is a reliable vacuum system. The vacuum system is responsible for creating and maintaining a strong suction force that securely holds the glass panel in place during lifting and transportation. A high-quality vacuum system should have a robust pump capable of generating sufficient suction power to handle the weight of the glass. Additionally, it should include a vacuum gauge or indicator that allows operators to monitor the vacuum level and ensure it remains within the safe range.

Another crucial safety feature is a fail-safe mechanism that prevents the glass from falling in the event of a power failure or loss of vacuum pressure. This mechanism typically consists of a backup power source, such as a battery or a generator, that kicks in automatically when the primary power source fails. It ensures that the glass remains securely held by the lifter, preventing accidents and damage to the glass.

To further enhance safety, some pneumatic glass lifters are equipped with an audible and visual alarm system. This system alerts operators if the vacuum pressure drops below a certain threshold or if any other malfunction occurs. The alarms serve as a warning to operators, allowing them to take immediate action and prevent accidents before they happen.

In addition to these safety features, it is essential to consider the ergonomics of the pneumatic glass lifter. A well-designed lifter should have adjustable handles and controls that allow operators to maintain a comfortable and natural posture while operating the device. This helps reduce the risk of strain or injury to the operator’s back, shoulders, and arms.

Furthermore, a pneumatic glass lifter should have a sturdy and stable construction to ensure safe and reliable operation. It should be made of high-quality materials that can withstand the rigors of heavy-duty use. The lifter should also have a non-slip base or feet to prevent it from sliding or tipping over during operation.

Lastly, it is crucial to consider the ease of maintenance and servicing of the pneumatic glass lifter. Look for a lifter that has easily accessible components, such as filters and seals, which may require regular cleaning or replacement. A lifter with a user-friendly design and clear instructions for maintenance will help ensure that it remains in optimal working condition, reducing the risk of malfunctions and accidents.

In conclusion, when choosing a pneumatic glass lifter, prioritizing safety features is of utmost importance. Look for a lifter with a reliable vacuum system, a fail-safe mechanism, and an audible and visual alarm system. Consider the ergonomics, construction, and ease of maintenance of the lifter to ensure safe and efficient glass handling operations. By selecting a pneumatic glass lifter with these top safety features, you can protect your workers and valuable glass materials from accidents and damage.

Efficiency and Performance of Pneumatic Glass Lifters

Pneumatic glass lifters are essential tools in the construction and manufacturing industries. They are designed to lift and transport heavy glass panels with ease and precision. When choosing a pneumatic glass lifter, it is important to consider its efficiency and performance. In this article, we will discuss the top features to look for in a pneumatic glass lifter to ensure optimal efficiency and performance.

One of the key features to consider is the lifting capacity of the glass lifter. Different models have different weight capacities, so it is important to choose one that can handle the weight of the glass panels you will be working with. It is always better to choose a glass lifter with a higher lifting capacity than you need, as this will provide a safety margin and prevent any accidents or damage to the glass panels.

Another important feature to look for is the suction cup configuration. The suction cups are responsible for gripping the glass panels securely. It is important to choose a glass lifter with suction cups that are specifically designed for glass lifting. These suction cups should be made of high-quality materials that provide a strong grip and prevent any slippage during lifting. Additionally, the suction cups should be adjustable to accommodate different sizes and shapes of glass panels.

The control system of the glass lifter is also a crucial feature to consider. A good glass lifter should have a user-friendly control system that allows for easy operation. It should have intuitive controls that are easy to understand and operate. Additionally, the control system should provide precise control over the lifting and lowering of the glass panels, allowing for smooth and accurate positioning.

The power source of the glass lifter is another important consideration. Pneumatic glass lifters are powered by compressed air, which is supplied by an air compressor. It is important to choose a glass lifter that is compatible with the air compressor you have or plan to use. Additionally, the glass lifter should have a reliable and efficient air supply system that ensures consistent and uninterrupted operation.

Safety features are also crucial when choosing a pneumatic glass lifter. Look for features such as safety sensors that detect any obstructions or irregularities during lifting. These sensors will automatically stop the lifting process to prevent any accidents or damage. Additionally, the glass lifter should have a backup power source or emergency release system in case of power failure or other emergencies.

Finally, consider the overall build quality and durability of the glass lifter. It should be made of high-quality materials that can withstand the rigors of heavy-duty lifting. Look for features such as reinforced frames and sturdy construction that ensure long-lasting performance.

In conclusion, when choosing a pneumatic glass lifter, it is important to consider its efficiency and performance. Look for features such as lifting capacity, suction cup configuration, control system, power source, safety features, and build quality. By considering these features, you can ensure that you choose a glass lifter that meets your specific needs and provides optimal efficiency and performance.

Versatility and Adaptability of Pneumatic Glass Lifters

Pneumatic glass lifters have become an essential tool in the construction and manufacturing industries. These devices are designed to lift and transport heavy glass panels with ease and precision. When it comes to choosing the right pneumatic glass lifter, there are several key features that you should consider. In this article, we will explore the versatility and adaptability of pneumatic glass lifters, and why these features are crucial for any lifting operation.

One of the top features to look for in a pneumatic glass lifter is its versatility. A versatile lifter is capable of handling a wide range of glass sizes and weights. This is important because glass panels come in various dimensions and thicknesses, and you need a lifter that can accommodate these variations. A versatile lifter will have adjustable suction cups or pads that can be easily repositioned to fit different glass sizes. This allows you to use the same lifter for different projects, saving you time and money.

Another important feature to consider is the lifter’s adaptability. An adaptable lifter is one that can be used in different working environments and conditions. For example, if you are working on a construction site, you may need a lifter that can handle rough terrain or uneven surfaces. In this case, look for a lifter with large, rugged wheels that can easily navigate through obstacles. Similarly, if you are working in a confined space, you may need a lifter with a compact design that can maneuver easily in tight corners.

Furthermore, an adaptable lifter should also have a wide range of lifting capacities. This means that it should be able to lift both light and heavy glass panels. Some lifters have a lifting capacity of up to 1,000 pounds, while others can handle even heavier loads. The lifting capacity of the lifter should be determined by the weight of the glass panels you will be working with. It is always better to choose a lifter with a higher lifting capacity to ensure that it can handle any glass panel you encounter.

In addition to versatility and adaptability, it is also important to consider the safety features of a pneumatic glass lifter. Safety should always be a top priority when working with heavy glass panels. Look for a lifter that has a reliable suction system that can securely hold the glass in place. The lifter should also have a fail-safe mechanism that prevents the glass from falling in case of a power failure or sudden loss of pressure. Additionally, the lifter should have a sturdy frame and construction to ensure stability during lifting operations.

In conclusion, when choosing a pneumatic glass lifter, it is important to consider its versatility and adaptability. A versatile lifter can handle different glass sizes and weights, allowing you to use it for various projects. An adaptable lifter can be used in different working environments and conditions, making it suitable for a wide range of applications. Additionally, the lifter should have a wide range of lifting capacities and safety features to ensure efficient and secure lifting operations. By considering these top features, you can find the perfect pneumatic glass lifter for your needs.