The Importance of Regular Cleaning and Maintenance for Vacuum Glass Lifter Suckers

Vacuum glass lifter suckers are essential tools for professionals in the glass industry. They are used to lift and transport heavy glass panels, making the job easier and safer. However, like any other tool, vacuum glass lifter suckers require regular cleaning and maintenance to ensure their optimal performance and longevity.

Regular cleaning and maintenance of vacuum glass lifter suckers are crucial for several reasons. Firstly, it helps to prevent the buildup of dirt, dust, and debris on the suction cups. Over time, these particles can affect the suction power of the lifter, making it less effective in gripping and lifting glass panels. By regularly cleaning the suction cups, you can ensure that they remain clean and free from any obstructions.

Secondly, regular maintenance allows you to inspect the lifter for any signs of wear and tear. Vacuum glass lifter suckers are subjected to a lot of stress and strain during their use, and this can lead to the deterioration of certain components. By regularly inspecting the lifter, you can identify any damaged or worn-out parts and replace them before they cause any further damage or compromise the safety of the lifter.

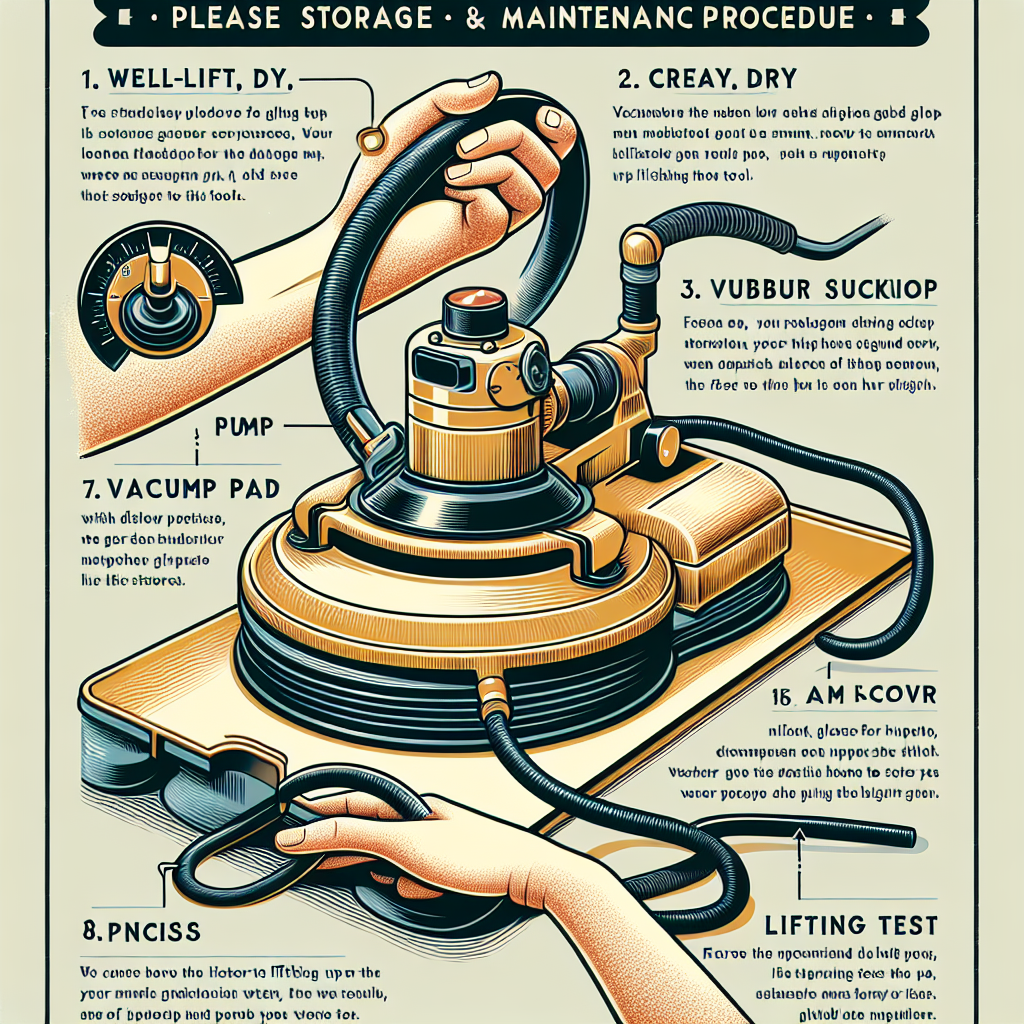

To properly clean and maintain your vacuum glass lifter sucker, you will need a few basic tools and materials. Start by removing the suction cups from the lifter. This can usually be done by unscrewing them or releasing them from their attachment points. Once the suction cups are removed, inspect them for any signs of damage or wear. If you notice any cracks or tears, it is best to replace them with new ones.

Next, clean the suction cups thoroughly using a mild detergent and warm water. Gently scrub the cups with a soft brush to remove any dirt or debris. Rinse them well and allow them to air dry completely before reattaching them to the lifter. It is important to ensure that the suction cups are completely dry before using the lifter again to prevent any slipping or loss of suction power.

While cleaning the suction cups is essential, it is also important to pay attention to other parts of the lifter. Inspect the handle, frame, and any other components for any signs of damage or wear. If you notice any loose screws or bolts, tighten them to ensure the stability and safety of the lifter. Lubricate any moving parts with a silicone-based lubricant to keep them functioning smoothly.

In addition to regular cleaning and maintenance, it is also important to store your vacuum glass lifter sucker properly. When not in use, store the lifter in a clean and dry environment, away from direct sunlight and extreme temperatures. This will help to prevent any damage to the lifter and prolong its lifespan.

In conclusion, regular cleaning and maintenance are essential for the proper functioning and longevity of vacuum glass lifter suckers. By cleaning the suction cups and inspecting the lifter for any signs of wear and tear, you can ensure that it remains in optimal condition. Proper storage is also important to prevent any damage when the lifter is not in use. By following these simple steps, you can keep your vacuum glass lifter sucker in top shape and ensure its effectiveness and safety for years to come.

Best Practices for Storing Vacuum Glass Lifter Suckers to Ensure Longevity

Vacuum glass lifter suckers are essential tools for professionals in the glass industry. These devices are designed to lift and transport heavy glass panels with ease, making them indispensable for tasks such as window installation, glass fabrication, and other construction projects. To ensure the longevity and optimal performance of your vacuum glass lifter sucker, it is crucial to store and maintain it properly. In this article, we will discuss the best practices for storing vacuum glass lifter suckers.

First and foremost, it is important to clean the vacuum glass lifter sucker after each use. Glass panels often leave residue or debris on the suction cups, which can affect the suction power and overall performance of the lifter. To clean the sucker, use a mild detergent and warm water. Gently scrub the suction cups with a soft brush or sponge, ensuring that all dirt and grime are removed. Rinse thoroughly and allow the sucker to air dry before storing it.

Once the vacuum glass lifter sucker is clean and dry, it is time to store it properly. The ideal storage location should be cool, dry, and away from direct sunlight. Excessive heat or moisture can damage the rubber suction cups and compromise their effectiveness. It is also important to avoid storing the sucker in an area with extreme temperature fluctuations, as this can cause the rubber to expand or contract, leading to potential damage.

To prevent any accidental damage, it is advisable to store the vacuum glass lifter sucker in a dedicated case or box. This will protect it from dust, dirt, and potential impacts during storage. If a dedicated case is not available, wrap the sucker in a soft cloth or towel before placing it in a secure location. Avoid stacking heavy objects on top of the sucker, as this can deform the suction cups and affect their performance.

Regular inspection is another crucial aspect of maintaining your vacuum glass lifter sucker. Before each use, carefully examine the suction cups for any signs of wear, cracks, or damage. If any issues are detected, it is important to replace the suction cups immediately. Using a damaged sucker can lead to accidents or damage to the glass panels being lifted.

In addition to regular cleaning and inspection, it is recommended to lubricate the suction cups periodically. This will help maintain their flexibility and ensure a strong seal. Apply a small amount of silicone lubricant to the suction cups and spread it evenly with a clean cloth. Be cautious not to use excessive lubricant, as this can cause the cups to become slippery and compromise their grip.

Lastly, it is essential to follow the manufacturer’s guidelines and recommendations for storing and maintaining your specific vacuum glass lifter sucker model. Different models may have specific requirements or additional steps that need to be followed. Always refer to the user manual or contact the manufacturer for any specific instructions.

In conclusion, proper storage and maintenance are crucial for ensuring the longevity and optimal performance of your vacuum glass lifter sucker. Clean the sucker after each use, store it in a cool and dry location, and inspect it regularly for any signs of wear or damage. By following these best practices, you can extend the lifespan of your vacuum glass lifter sucker and continue to rely on it for your glass handling needs.

How to Extend the Lifespan of Your Vacuum Glass Lifter Sucker through Proper Storage and Maintenance

How to Properly Store and Maintain Your Vacuum Glass Lifter Sucker

Vacuum glass lifter suckers are essential tools for lifting and moving heavy glass panels. They provide a secure grip and make the task much easier and safer. However, like any tool, proper storage and maintenance are crucial to ensure their longevity and optimal performance. In this article, we will discuss some important tips on how to extend the lifespan of your vacuum glass lifter sucker through proper storage and maintenance.

First and foremost, it is important to clean the vacuum glass lifter sucker after each use. Glass panels often leave residue on the suction cups, which can affect their performance over time. To clean the sucker, use a mild detergent and warm water. Gently scrub the suction cups with a soft brush or sponge, making sure to remove any dirt or debris. Rinse thoroughly and allow the sucker to air dry before storing it.

Once the vacuum glass lifter sucker is clean and dry, it is important to store it properly. Avoid leaving it exposed to direct sunlight or extreme temperatures, as this can damage the rubber suction cups. Instead, find a cool and dry place to store the sucker. If possible, keep it in its original case or a dedicated storage box to protect it from dust and other contaminants.

In addition to proper cleaning and storage, regular inspection is also necessary to ensure the vacuum glass lifter sucker is in good working condition. Check the suction cups for any signs of wear or damage. If you notice any cracks, tears, or deformities, it is important to replace them immediately. Damaged suction cups can compromise the lifter’s grip and pose a safety risk.

Furthermore, inspect the vacuum pump and hoses for any leaks or damage. A faulty pump or hose can significantly affect the lifter’s performance. If you notice any issues, it is best to have them repaired or replaced by a professional. Regular maintenance and servicing can help identify and address any potential problems before they escalate.

When using the vacuum glass lifter sucker, it is important to follow the manufacturer’s guidelines and recommendations. Overloading the lifter or using it for purposes other than lifting glass panels can cause unnecessary strain and damage. Always check the weight capacity of the lifter and ensure that it is suitable for the task at hand.

Lastly, it is important to handle the vacuum glass lifter sucker with care. Avoid dropping or mishandling it, as this can cause damage to the suction cups or other components. When not in use, store the lifter in a secure location where it is less likely to be accidentally knocked over or damaged.

In conclusion, proper storage and maintenance are essential for extending the lifespan of your vacuum glass lifter sucker. Regular cleaning, proper storage, and regular inspection can help ensure optimal performance and safety. By following these tips, you can enjoy the benefits of your vacuum glass lifter sucker for years to come.